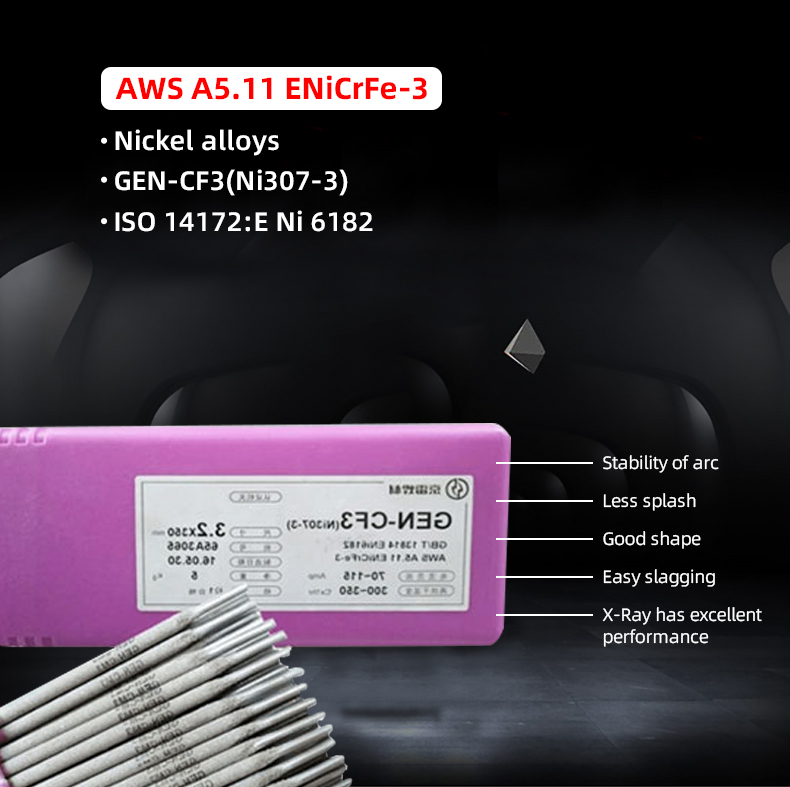

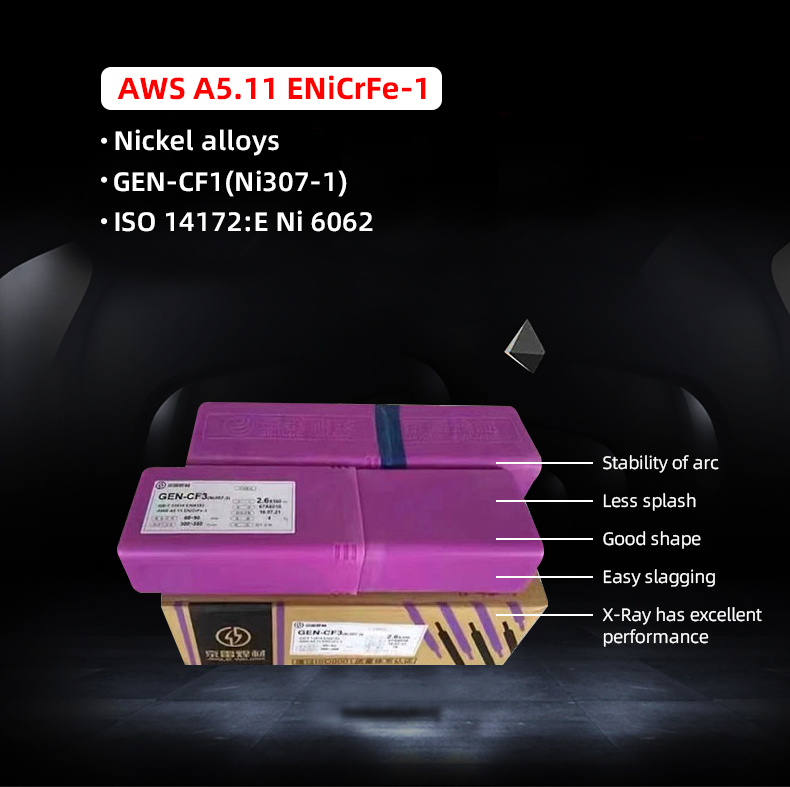

Nickel alloys Phau ntawv electrode ENiCrFe-3 Welding jointing

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Fe | Nb+Ta | P | S | |

| GB/T RULES | 0.10 | 5.0-10.0 Nws | 1.00 Nws | 13.0-17.0 Nws | ≥60 | 10.00 Nws | 1.0-3.5 | 0.02 ib | 0.015 ib | |

| AWS RULES | 0.10 | 5.0-9.5 | 1.00 Nws | 13.0-17.0 Nws | ≥59 | 10.00 Nws | 1.0-2.5 hli | 0.03 ib | 0.015 ib | |

| EXAMPLE VALUE | 0.046 ib | 7.6 | 0.45 ib | 15.7 ib | 15.7 ib | 3.56 ib | 1.76 ib | 0.005 ib | 0.004 ib | |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 360 | 550 | - | 27 | ||||

| AWS RULES | - | 550 | - | 30 | ||||

| EXAMPLE VALUE | 410 | 650 | - | 40 | ||||

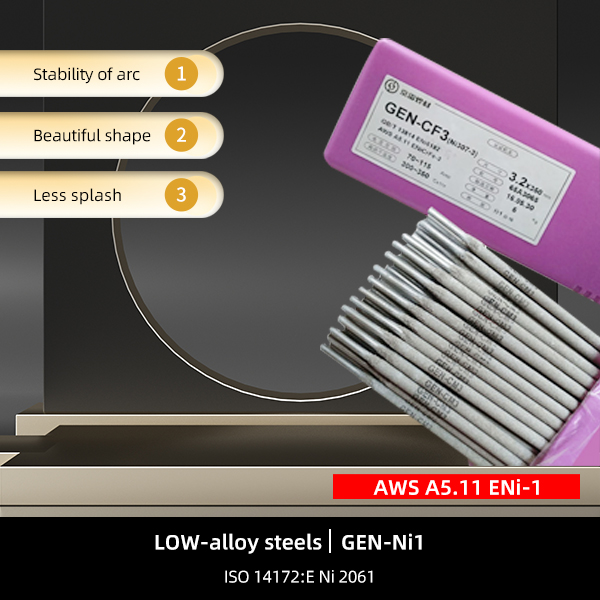

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 300 | 3.2 * 350 | 4.0 * 350 | ||||||||

| ELECTRICITY (Amp) | H/W | 69-95 : kuv | 70-115 : kuv | 95-145 : kuv | |||||||

| O/W | 55-80 : kuv | 65-110 : kuv | 80-130 : kuv | ||||||||

Tsawg hydrogen hom tes electrode, nominal muaj pes tsawg leeg (qhov hnyav feem pua) yog 65Ni-15Cr-8Fe-7.5Mn-2Nb + Ta, rau nickel-chrome-hlau alloy electrode.

Vim muaj cov ntsiab lus siab ntawm cov hlau, nws muaj qhov kub thiab txias zog thiab oxidation tsis kam thiab tuaj yeem hloov mus rau qhov kub thiab txias ntawm qhov kub qis mus rau 480 ℃.

ruaj khov arc, zoo nkauj sib sau, me ntsis txaws, yooj yim slag tshem tawm, zoo porosity tsis kam, txhua yam khoom ntawm molten hlau yog ruaj khov.

-

300,000-tuj offshore Floating Production thiab Storage Tanker (FPSO)

Harbin hluav taws xob peb qhov rooj CMT

-

Zhejiang Satellite Zog 3 × 60,000 m³ LPG cia tank

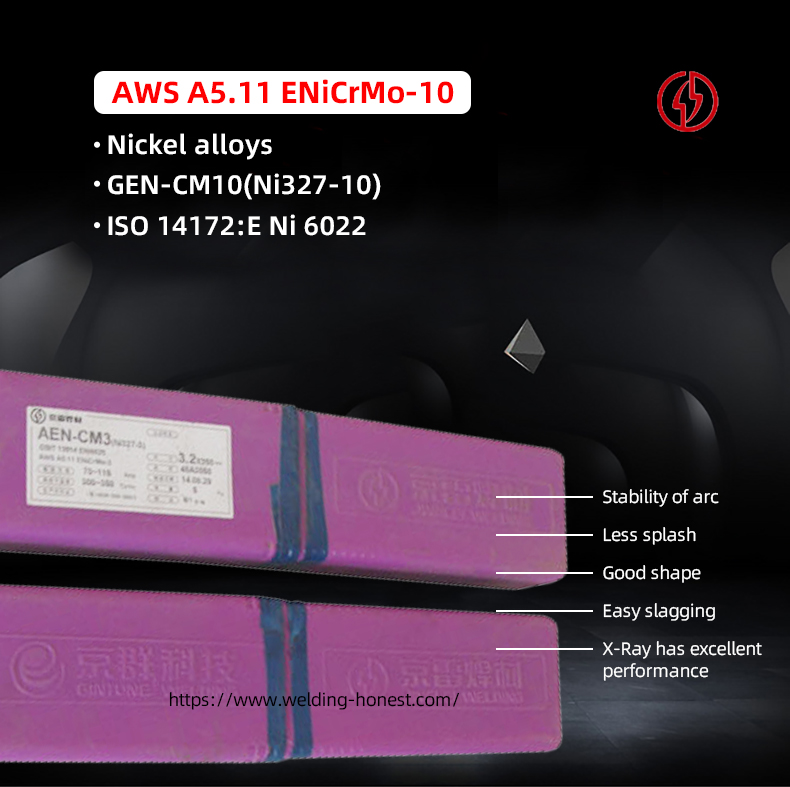

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Fe | Nb+Ta | P | S | |

| GB/T RULES | 0.10 | 5.0-10.0 Nws | 1.00 Nws | 13.0-17.0 Nws | ≥60 | 10.00 Nws | 1.0-3.5 | 0.02 ib | 0.015 ib | |

| AWS RULES | 0.10 | 5.0-9.5 | 1.00 Nws | 13.0-17.0 Nws | ≥59 | 10.00 Nws | 1.0-2.5 hli | 0.03 ib | 0.015 ib | |

| EXAMPLE VALUE | 0.046 ib | 7.6 | 0.45 ib | 15.7 ib | 15.7 ib | 3.56 ib | 1.76 ib | 0.005 ib | 0.004 ib | |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 360 | 550 | - | 27 | ||||

| AWS RULES | - | 550 | - | 30 | ||||

| EXAMPLE VALUE | 410 | 650 | - | 40 | ||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 300 | 3.2 * 350 | 4.0 * 350 | ||||||||

| ELECTRICITY (Amp) | H/W | 69-95 : kuv | 70-115 : kuv | 95-145 : kuv | |||||||

| O/W | 55-80 : kuv | 65-110 : kuv | 80-130 : kuv | ||||||||