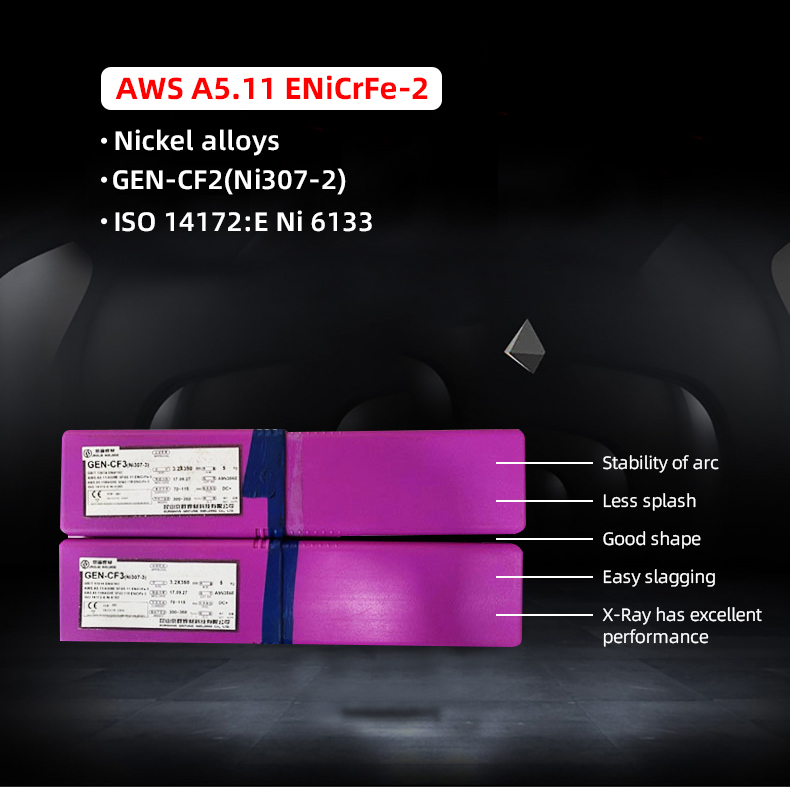

Nickel alloys Phau ntawv electrode ENiCrFe-2 Vuam khoom

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Fe | Nb+Ta | P | S | Mo | ||

| GB/T RULES | 0.10 | 1.0-3.5 Nws | 0.80 ib | 13.0-17.0 Nws | ≥62 | 12.00 Nws | 0.5-3.0 | 0.02 ib | 0.015 ib | 0.5-3.0 | ||

| AWS RULES | 0.10 | 1.0-3.5 Nws | 0.75 ib | 13.0-17.0 Nws | ≥62 | 12.00 Nws | 0.5-3.0 | 0.03 ib | 0.02 ib | 0.5-2.5 hli | ||

| EXAMPLE VALUE | 0.036 ib | 3.19 ib | 0.48 ib | 14.6 ib | 70.8 ua | 7.04 ib | 1.67 ib | 0.009 ib | 0.003 ib | 1.63 ib | ||

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 360 | 550 | - | 27 | ||||

| AWS RULES | - | 550 | - | 30 | ||||

| EXAMPLE VALUE | 430 | 660 | - | 44 | ||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 300 | 3.2 * 350 | 4.0 * 350 | ||||||||

| ELECTRICITY (Amp) | H/W | 69-95 : kuv | 70-115 : kuv | 95-145 : kuv | |||||||

| O/W | 55-80 : kuv | 65-110 : kuv | 80-130 : kuv | ||||||||

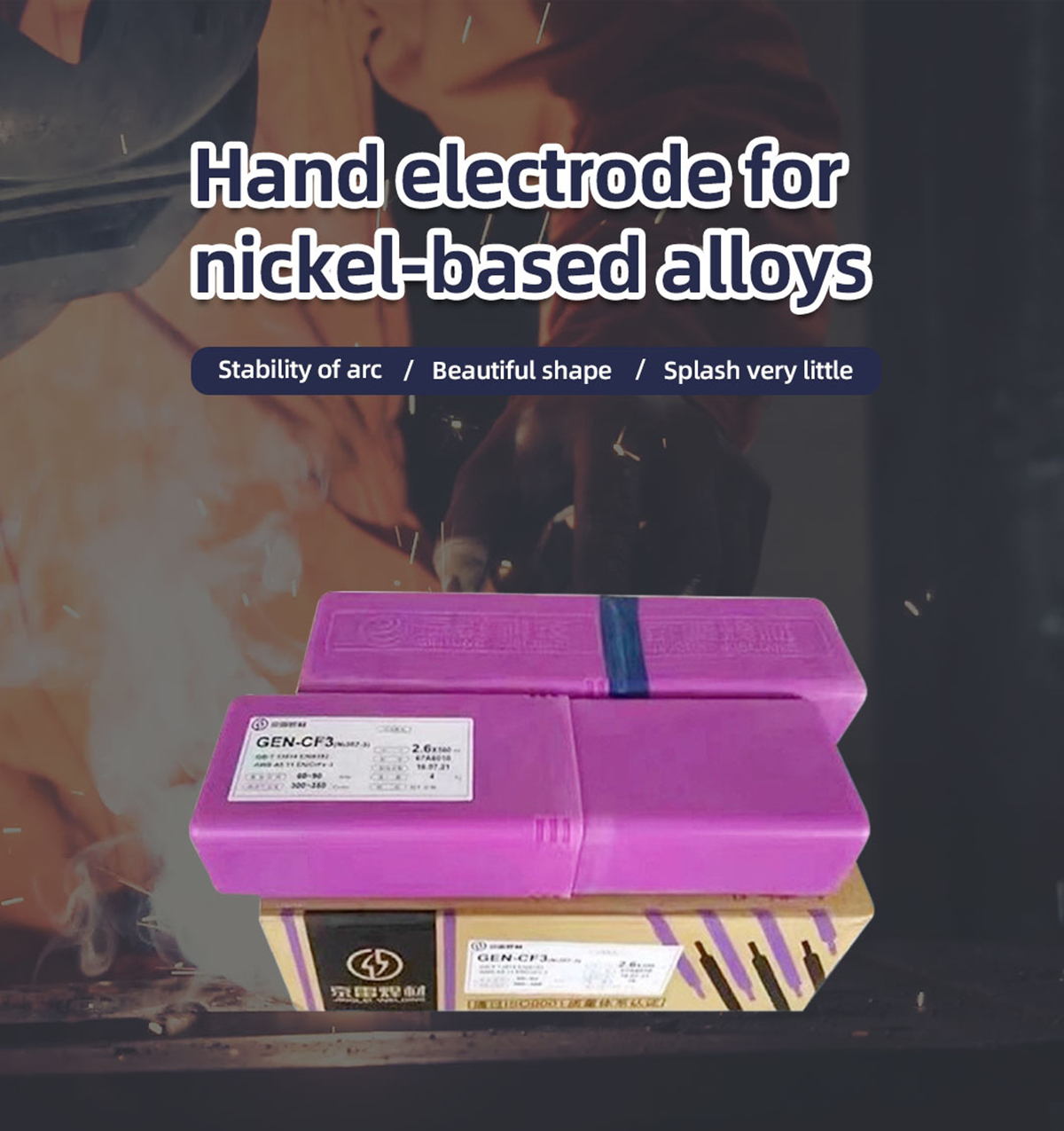

Tsawg hydrogen hom tes electrode, nominal muaj pes tsawg leeg (qhov hnyav feem pua) yog 7ONi-15Cr-8Fe-2Mn-2Nb + Ta-1.5Mo, rau nickel-chrome-hlau alloy electrode.

Lub hauv paus hlau tuaj yeem raug forged lossis cam khwb cia (qib weldable) thiab tuaj yeem hloov kho rau qhov kub thiab txias xws li qhov kub thiab txias mus txog 980 ° C;Txawm li cas los xij, thaum qhov kub siab tshaj 820 ℃, oxidation kuj thiab lub zog yuav deteriorate.

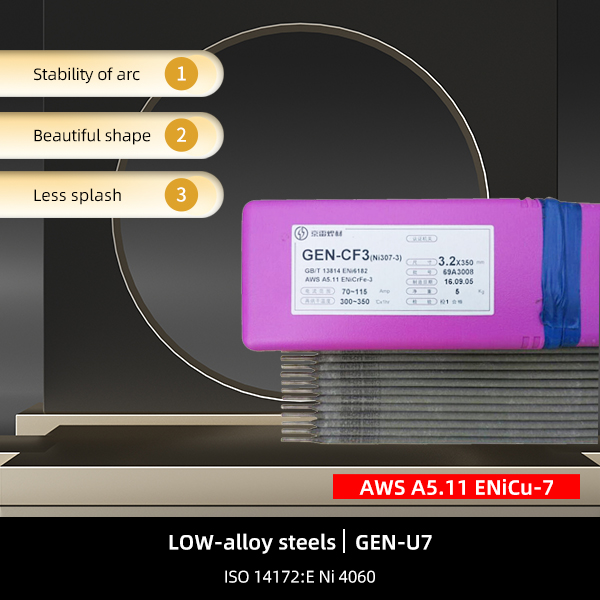

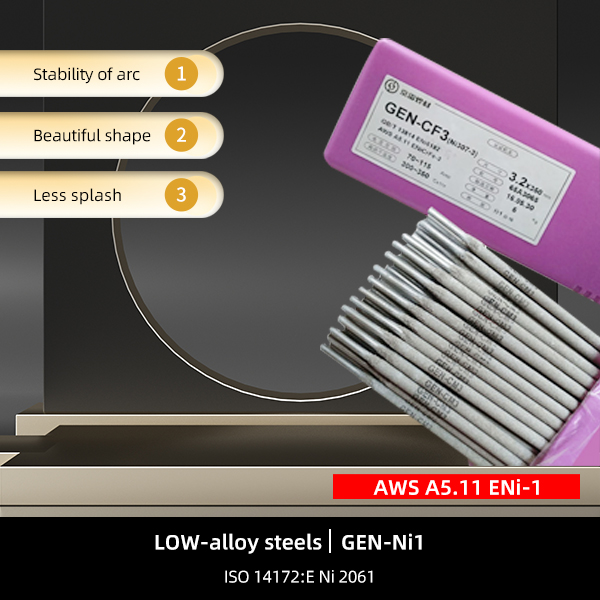

Ruaj khov arc, zoo nkauj tsim, me ntsis txaws, yooj yim slag tshem tawm, zoo porosity tsis kam, txhua yam khoom ntawm cov hlau molten ruaj khov, thiab muaj qhov kub thiab txias tsis kam thiab kub oxidation tsis kam.

-

10000TEU thawv nkoj

-

Kev siv hluav taws xob thermal

Zhangjiagang CIMC Sundayin Cryogenic Equipment Co., Ltd.Cryogenic Container (LNG Filling chaw nres tsheb)

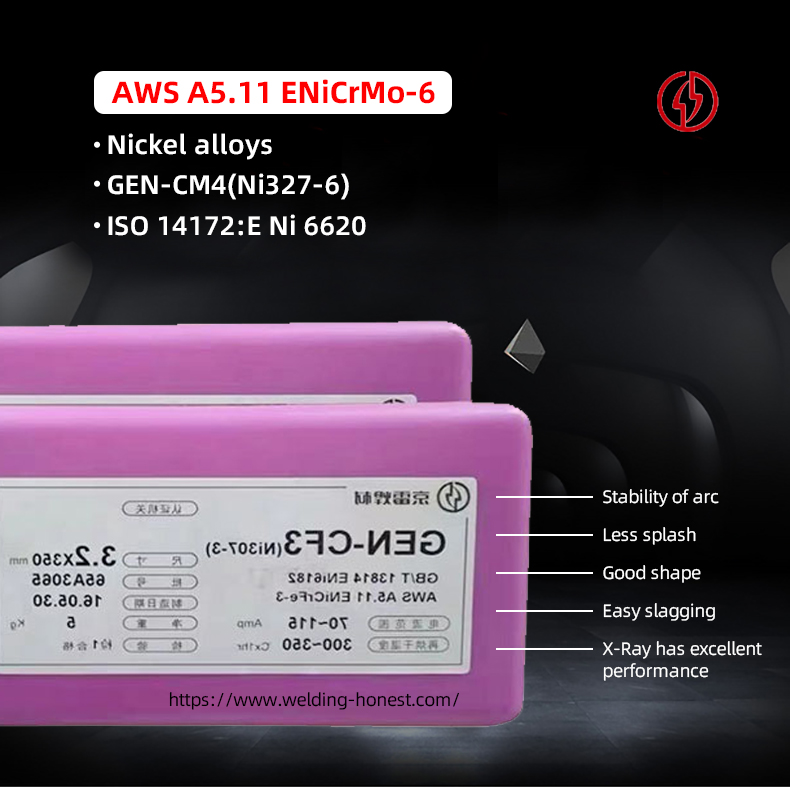

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Fe | Nb+Ta | P | S | Mo | ||

| GB/T RULES | 0.10 | 1.0-3.5 Nws | 0.80 ib | 13.0-17.0 Nws | ≥62 | 12.00 Nws | 0.5-3.0 | 0.02 ib | 0.015 ib | 0.5-3.0 | ||

| AWS RULES | 0.10 | 1.0-3.5 Nws | 0.75 ib | 13.0-17.0 Nws | ≥62 | 12.00 Nws | 0.5-3.0 | 0.03 ib | 0.02 ib | 0.5-2.5 hli | ||

| EXAMPLE VALUE | 0.036 ib | 3.19 ib | 0.48 ib | 14.6 ib | 70.8 ua | 7.04 ib | 1.67 ib | 0.009 ib | 0.003 ib | 1.63 ib | ||

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 360 | 550 | - | 27 | ||||

| AWS RULES | - | 550 | - | 30 | ||||

| EXAMPLE VALUE | 430 | 660 | - | 44 | ||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 300 | 3.2 * 350 | 4.0 * 350 | ||||||||

| ELECTRICITY (Amp) | H/W | 69-95 : kuv | 70-115 : kuv | 95-145 : kuv | |||||||

| O/W | 55-80 : kuv | 65-110 : kuv | 80-130 : kuv | ||||||||