Nickel alloys TIG ERNiCrFe-7A Soldering sib koom ua ke

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | Nb+Ta | P | S |

| GB/T RULES | - | - | - | - | - | - | - | - | - | - |

| AWS RULES | 0.04 ib | 1.00 Nws | 0.50 ib | 28.0-31.5 Nws | Rem | 0.50 ib | 7.0-11.0 Nws | 0.5-1.0 | 0.02 ib | 0.015 ib |

| EXAMPLE VALUE | 0.028 ib | 0.15 | 0.11 | 29.8 ib | 59.03 Nws | 0.06 ib | 9.8 ib | 0.86 ib | 0.001 ib | 0.002 ib |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | Kev kho cua sov | ||||||

| GB/T RULES | - | - | - | - | - | ||||||

| AWS RULES | - | - | - | - | - | ||||||

| EXAMPLE VALUE | - | 760 ib | 133 / Chav ntsuas kub | 37 | 607 ° C * 25h | ||||||

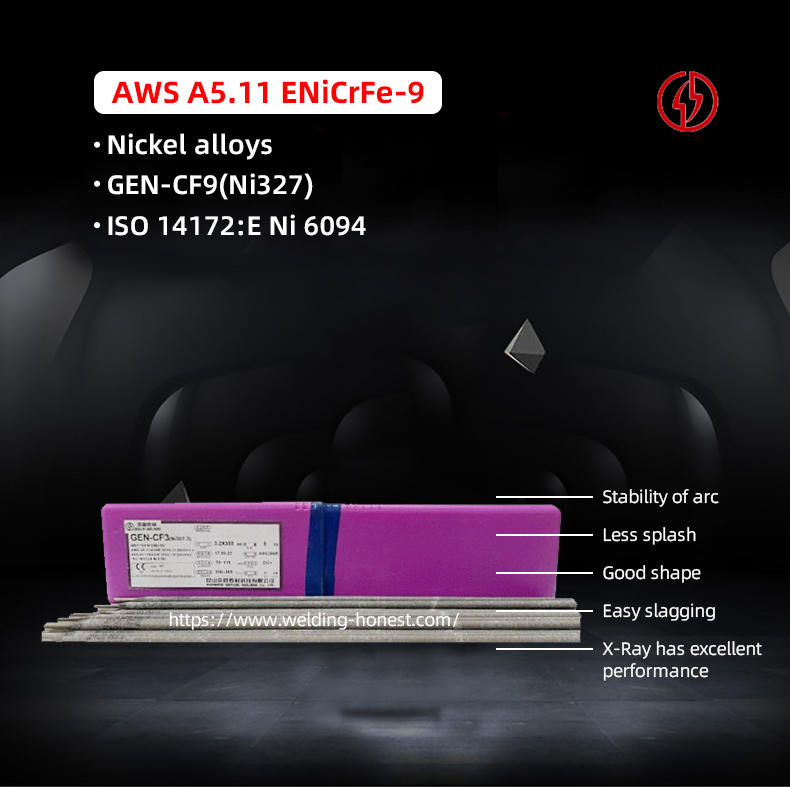

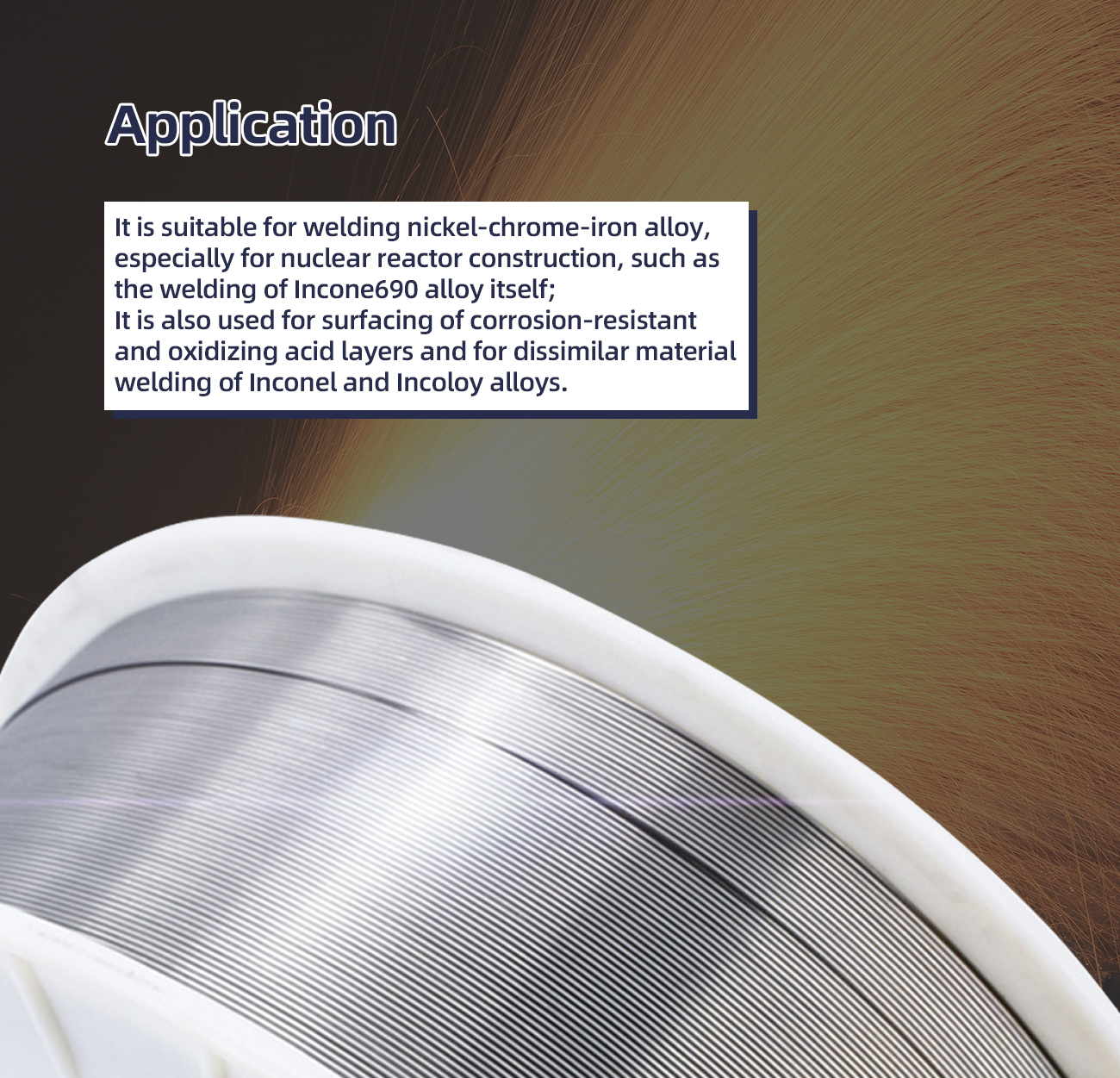

Nickel-chromium-hlau nickel-base alloy roj vuam hlau, nominal muaj pes tsawg leeg yog 60% Ni-29% Cr-9% Fe-0.75% Nb.

Cov khoom siv zoo ntawm cov hlau molten, tshwj xeeb tshaj yog tsis muaj cov yas tawg (DDC).

Cov ntsiab lus Cr siab ua rau nws muaj kev ntxhov siab zoo corrosion cracking kuj nyob rau hauv dej ntshiab ib puag ncig nyob rau hauv hluav taws xob mob. ruaj khov arc, zoo nkauj sib sau, zoo ntws ntawm molten hlau, nrog zoo heev vuam txheej txheem kev ua tau zoo.

-

Xinjiang Kela 2 Central Treatment Plant Project

-

Vuam khoom rau Silencer

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | Nb+Ta | P | S |

| GB/T RULES | - | - | - | - | - | - | - | - | - | - |

| AWS RULES | 0.04 ib | 1.00 Nws | 0.50 ib | 28.0-31.5 Nws | Rem | 0.50 ib | 7.0-11.0 Nws | 0.5-1.0 | 0.02 ib | 0.015 ib |

| EXAMPLE VALUE | 0.028 ib | 0.15 | 0.11 | 29.8 ib | 59.03 Nws | 0.06 ib | 9.8 ib | 0.86 ib | 0.001 ib | 0.002 ib |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | Kev kho cua sov | ||||||

| GB/T RULES | - | - | - | - | - | ||||||

| AWS RULES | - | - | - | - | - | ||||||

| EXAMPLE VALUE | - | 760 ib | 133 / Chav ntsuas kub | 37 | 607 ° C * 25h | ||||||

Sau koj cov lus ntawm no thiab xa tuaj rau peb