Ntauwd yog siv rau distillation, purification, absorption, distillation thiab lwm yam khoom siv tshuaj, feem ntau ntawm cov pej thuam li yuav tsum tau hu rau acid, alkali, ntsev, organic solvents thiab lwm yam corrosive media, yog li nws yog tsim nyog los surfacing ib tug loj cheeb tsam ntawm corrosion resistant txheej. nyob rau hauv lub tog raj kheej thiab sealing qhov chaw.Raws li ib txoj hauv kev zoo ntawm surfacing, strip surfacing yog siv dav hauv ntauwd vuam ntawm cov khoom siv tshuaj.

Cov tsoos electrode surfacing thev naus laus zis yog ob txheej txheej submerged arc surfacing thev naus laus zis nrog cov txheej txheem hloov pauv thiab txheej txheej corrosion, tab sis cov thev naus laus zis no tau tsim lub voj voog ntev thiab cov nqi tsim khoom siab.Txhawm rau daws qhov teeb meem no, JingQunCo tau tsim ib txheej txheej txheej vuam cov ntaub ntawv (GDS-309LA vuam sawb, GXS-ED308L electroslag flux), uas tuaj yeem ua tiav cov nyhuv ntawm ob txheej txheej nrog tsuas yog ib txheej txheej txheej, thiab tuaj yeem yooj yim. txheej txheem surfacing los ntawm ob-txheej surfacing rau ib-txheej surfacing.

Taw qhia txog cov khoom siv vuam

1.Cov tshuaj tiv thaiv

| Rules/Npe | C | Si | Mn | P | S | Cr | Ni | Nua ote |

| NB/T47018.5 EQ309LA | ≤ 0.030 | ≤ 1.00 | 0.5-2.5 hli | ≤ 0.025 | ≤ 0.015 | 21.0-23.0 Nws | 9.0-12.0 Nws | solder strip |

| GDS-309 LOJ | 0.018 ib | 0.34 ib | 1.90 ib | 0.017 ib | 0.001 ib | 21.96 Nws | 11.17 Nws | solder strip |

| Rules/Npe | NB/T47018.5 FZ308-D | GDS-309LA + GXS-ED308L solder strip + Flux ua ke | |||

| C | ≤ 0.05 | 0.028 ib | 0.028 ib | 0.029 ib | 0.029 ib |

| Si | ≤ 1.00 | 0.58 ib | 0.64 ib | 0.62 ib | 0.64 ib |

| Mn | ≤ 2.5 | 1.33 | 1.33 | 1.35 Nws | 1.33 |

| P | ≤ 0.030 | 0.018 ib | 0.018 ib | 0.018 ib | 0.017 ib |

| S | ≤ 0.020 | 0.004 ib | 0.004 ib | 0.004 ib | 0.004 ib |

| Cr | 18.0-21.0 Nws | 18.21 Nws | 18.47 Nws | 18.39 Nws | 18.28 Nws |

| Ni | 8.0-11.0 Nws | 10.12 Nws | 10.31 Nws | 10.27 Nws | 10.30 Nws |

| Nco tseg | tso hlau | Vuam nto | Hauv qab 1mm | Hauv qab 2 hli | Hauv qab 3mm |

2. Weld tsos

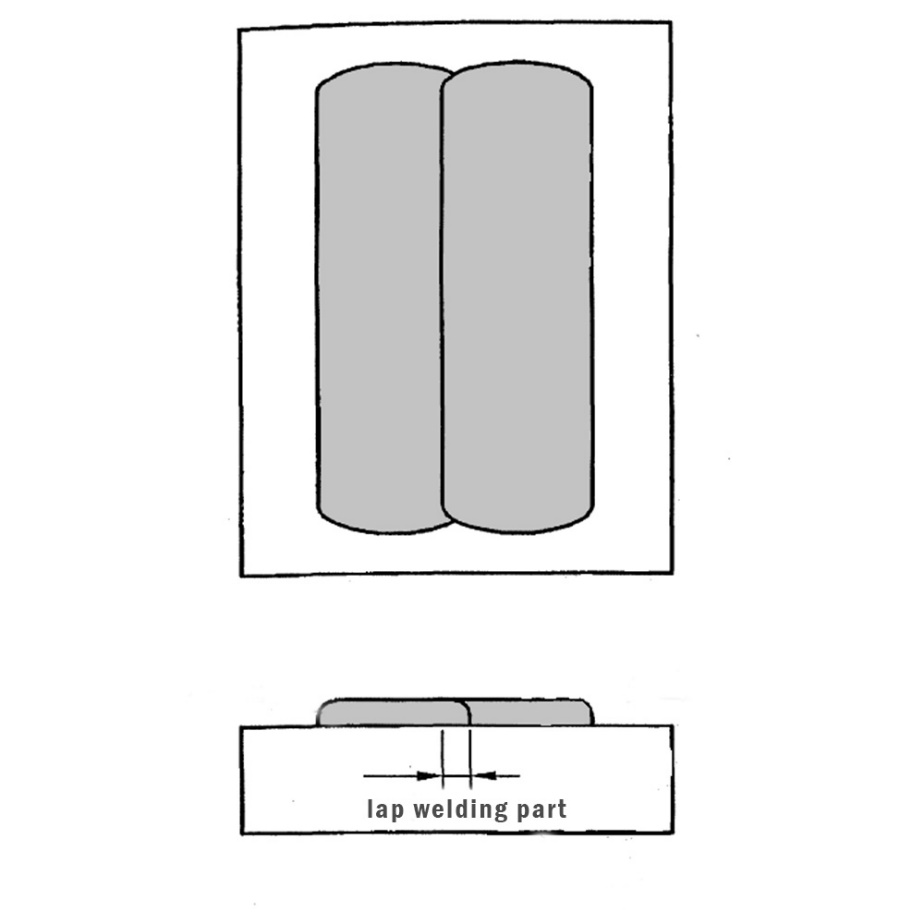

Pom zoo welding tsis

| Specification (hli) | 05 * 60 |

| Hluav taws xob (A) | 850-950 Nws |

| Qhov voltage (V) | 26-30 |

| WCeev ceev (mm / min) | 150 |

| LQhov siab (mm) | 35-40 |

| Lap vuam (mm / min) | 6-10 |

| Thickness ntawm flux kis (mm / min) | Asib 25 |

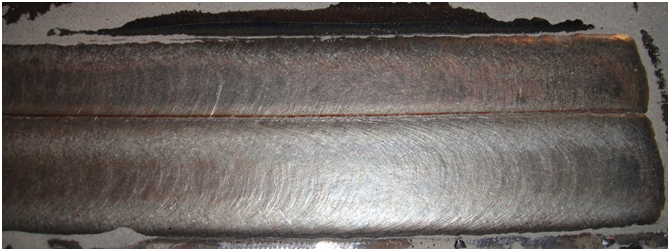

Weld pass thickness: txog 4.7mm

Weld dav: txog 62.5mm

Weld pass tsos: zoo nkauj zoo nkauj, weld nto yog tiaj tus, kev hloov pauv ntawm lub puab tsaig yog du.

3.Mechanical muaj peev xwm

Ferrite cov ntsiab lus (welded xeev)

| Solder strip + Flux ua ke | GDS-309LA + GXS-ED308L |

| Ntsuas tus nqi | Cov ntsiab lus ferrite yog hais txog 7FN, thiab cov ntsiab lus ferrite feem pua yog li 8% |

| Ntsuas txoj hauj lwm | Weld nto |

Test txoj kev: GB / T 1954-2008 "chromium-nickel austenitic stainless hlau weld ferrite cov ntsiab lus ntsuas txoj kev"

Khoov xeem:

as

620 ℃ * 20h

Cov txiaj ntsig kev xeem: lateral dabtsi yog khoov, indenter txoj kab uas hla 4T (40mm), khoov lub kaum sab xis 180 ° tsis muaj tawg.

Intergranular corrosion test

Raws li welded

620 ℃ * 20h

Test method: GB/T 4334-2020 Method E

Kev ntsuas tshuaj: tooj liab - tooj liab sulfate -16% sulfuric acid

Cov txiaj ntsig kuaj: Tsis muaj kev cuam tshuam ntawm intergranular corrosion

Micro metallography ntawm surfacing txheej

Raws li welded

Raws li welded

620 ℃ * 20h kev kho cua sov

620 ℃ * 20h kev kho cua sov

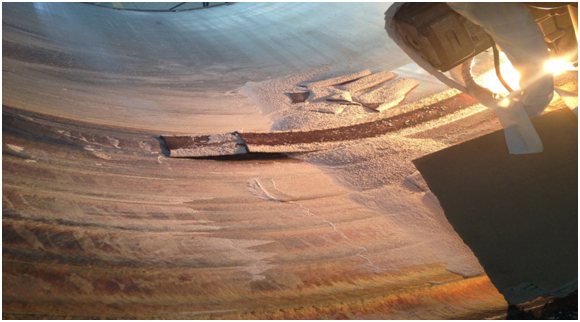

Daim ntawv thov engineering

1. Cov neeg siv khoom vuam txheej txheem kev soj ntsuam

2. Cov neeg siv khoom siv qhov chaw

Tom qab xyoo ntawm kev tshawb fawb thiab kev loj hlob, Jingqun ib txheej electroslag surfacing vuam cov ntaub ntawv kev ua tau zoo yog ruaj khov thiab txhim khu kev qha, muaj ntau yam engineering daim ntawv thov ua tiav.

Txais tos cov neeg muas zaub los sab laj thiab xaiv!

Xav paub ntau ntxiv ntxiv whatsapp + 86 13252436578

E-Mail:sale@welding-honest.com

Post lub sij hawm: Nov-04-2022