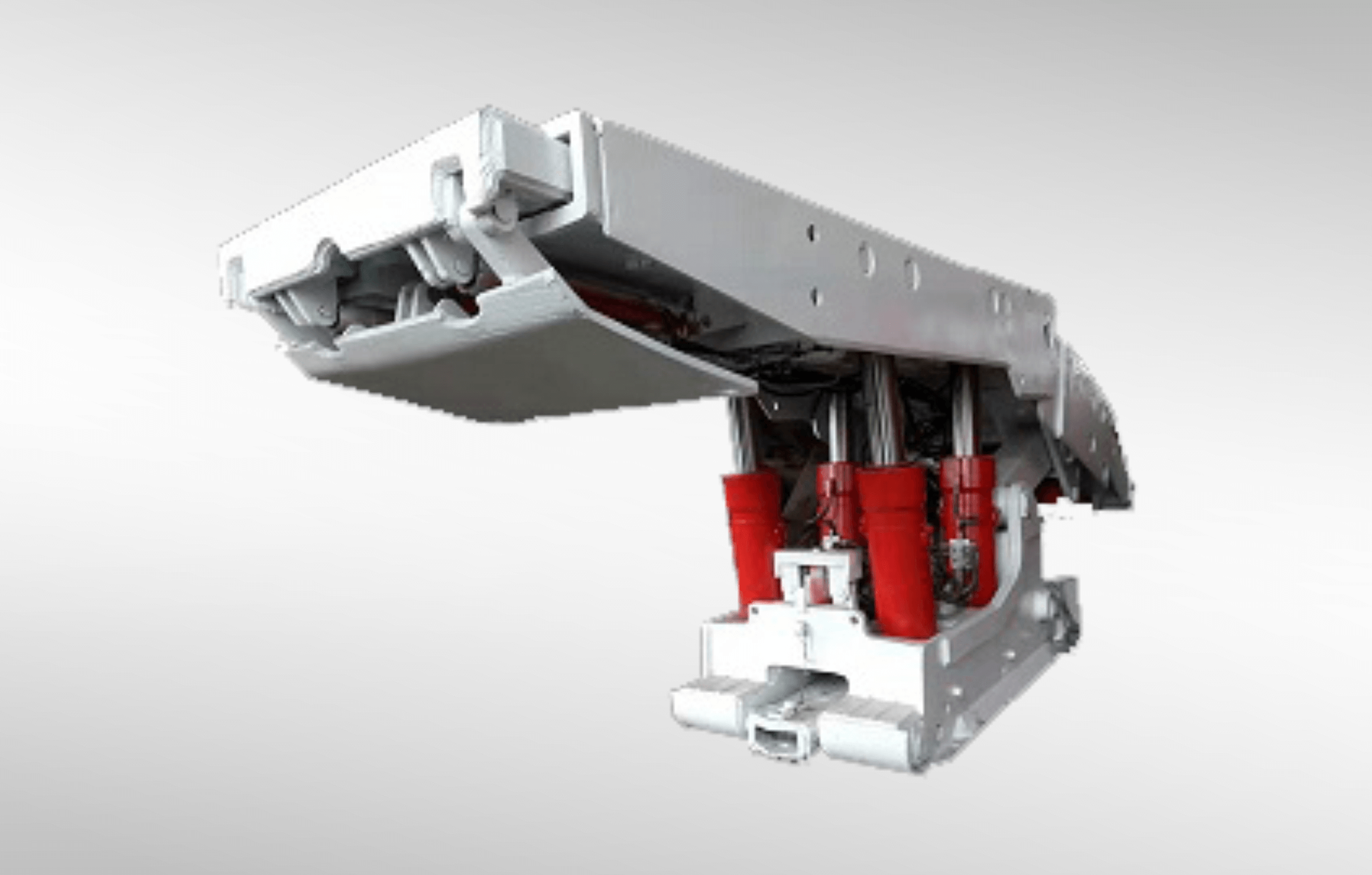

Nrog rau txoj kev loj hlob sai ntawm kev tsim cov tshuab tsim khoom thiab kev ua kom nrov ntawm cov qauv tsim ntawm cov khoom siv steel, Q890 high-strength steel daim hlau tau maj mam siv rau cov txheej txheem steel xws li thee mine hydraulic kev txhawb nqa, tsheb hnyav, thiab kev tsim kho tshuab, thiab feem ntau yog siv. hauv mines thiab ntau yam kev tsim kho engineering.Drilling rigs, hluav taws xob shovels, hluav taws xob log tsheb thauj khoom, tsheb mining, excavators, loaders, bulldozers, ntau hom cranes thiab lwm yam khoom siv kho tshuab.

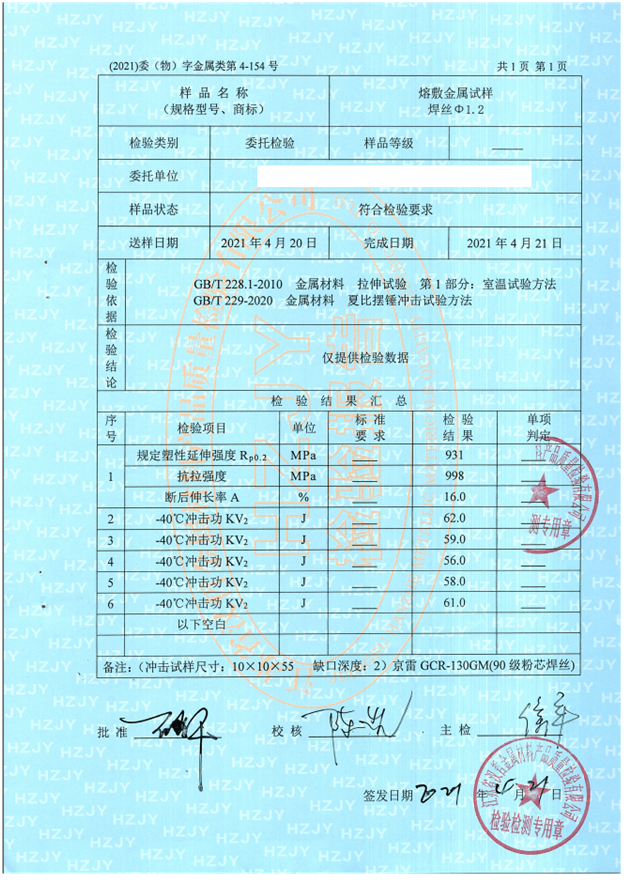

Q890 high-strength steel puag khoom (GB T 16270-2009)

1.Chemical muaj pes tsawg leeg ntawm cov khoom siv hauv paus

| Qauv | qw 890c | qw 890d | qw 890e | qw 890f | |

| Hlau Wt% | C | 0.20 ib | |||

| Si | 0.80 ib | ||||

| Mn | 2.00 Nws | ||||

| P | 0.025 ib | 0.020 ib | |||

| S | 0.015 ib | 0.010 ib | |||

| Cu | 0.50 ib | ||||

| Cr | 1.50 ib | ||||

| Ni | 2.00 Nws | ||||

| Mo | 0.70 ib | ||||

| B | 0.005 ib | ||||

| V | 0.12 | ||||

| Nb | 0.06 ib | ||||

| Ti | 0.05 Nws | ||||

2.Mechanical zog ntawm lub hauv paus hlau

| Qauv | qw 890c | qw 890d | qw 890e | qw 890f | |||

| Hlau Wt% | Thickness mm | ≤ 50 | Yield zog Mpa | 890 ua | |||

| 50-100 | 8 30 | ||||||

| 100-150 | - | ||||||

| Thickness mm | ≤ 50 | tensile zog Mpa | 940-1100 Nws | ||||

| 50-100 | 880-1100 Nws | ||||||

| 100-150 | - | ||||||

| elongation tom qab so% | 11 | ||||||

| Kev cuam tshuam lub zog nqus J / ℃ | 34/0 | 24/-20 | 27/-40 Nws | 27/-60 ib | |||

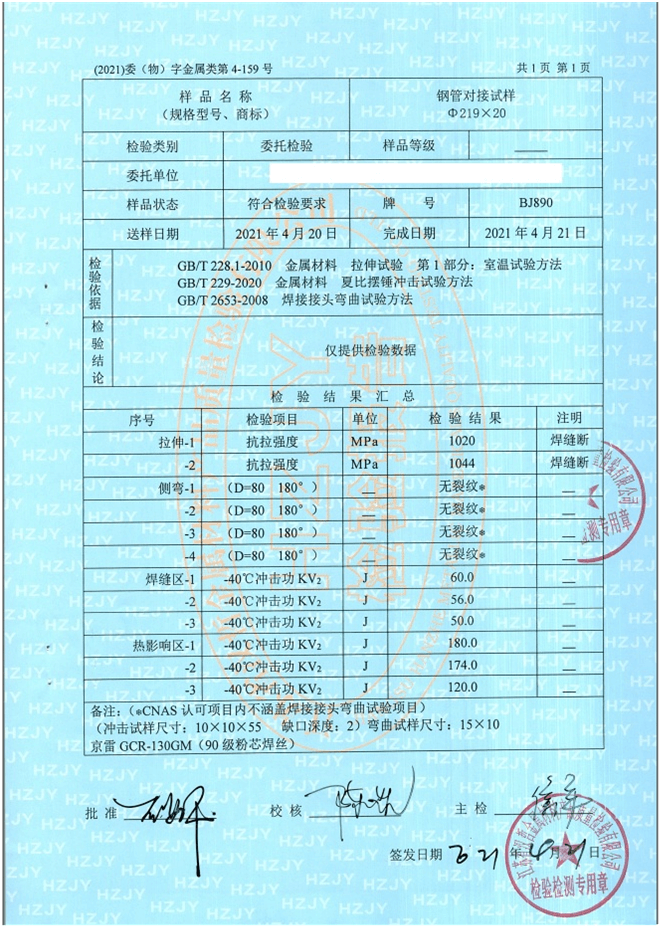

Txhawb nqa vuam consumables

| Hlau qeb | Cov hlau tsis muaj tooj liab | Hlau hmoov cored hlau |

| npe khoom | GMR-W80 | GCR-130 GM |

| Tus txheej txheem tswj hwm | AWS A5.28 ER120S-G | - |

3.Kev muaj pes tsawg leeg (tso hlau 80% Ar + 20% CO2)

| Qauv | GMR-W80 | GCR-130 GM | |

| Hlau Wt% | C | 0.08 ib | 0.06 ib |

| Mn | 1.81 ib | 1.92 ib | |

| Si | 0.79 ib | 0.33 ib | |

| Ni | 2.36 ib | 2.70 ib | |

| Cr | 4. Cov khoom siv hluav taws xob zoo (80% Ar + 20% CO2) 0.35 Nws | 0.54 ib | |

| Mo | 0.60 ib | 0.50 ib | |

| P | 0.007 ib | 0.008 ib | |

| S | 0.009 ib | 0.005 ib | |

| Nco tseg | filler hlau | tso hlau | |

4. Cov khoom siv hluav taws xob zoo (80% Ar + 20% CO2)

| Lub npe | GMR-W80 | GCR-130 GM |

| Yield zog Mpa | 900 | 930 ua |

| tensile zog Mpa | 950 ua | 990 ua |

| elongation tom qab so % | 17 | 16 |

| Kev cuam tshuam lub zog nqus J/℃ | 80/-40 | 60/-40 ib |

6.Recommended welding tsis

| Lub npe | GMR-W80 | GCR-130 GM | |

| Weld specification | hluav taws xob tam sim no A | 260 ± 20 | 270 ± 20 |

| Qhov hluav taws xob V | 27 ± 1 | 28 ± 1 | |

| vuam ceev mm / min | 350 ± 50 | 350 ± 50 | |

| Kub ℃ | 150 ± 15 | 150 ± 15 | |

Rau daim ntawv thov dav ntawm Q890 high-strength steel, tom qab xyoo ntawm kev tshawb fawb thiab kev loj hlob ntawm vuam consumables, peb muaj ob series ntawm kev txhawb nqa vuam consumables, khoom thiab hlau hmoov core, thiab muaj ntau yam engineering daim ntawv thov ua tiav.Txais tos cov neeg muas zaub los sab laj thiab xaiv!

Xav paub ntau ntxiv xa mus rau E-mail:export@welding-honest.com

Post lub sij hawm: Jan-18-2023