Thaum lub sij hawm hardfacing txheej txheem, cov kab nrib pleb feem ntau ua rau muaj teeb meem xws li rework thiab cov neeg siv khoom xa rov qab.Hardfacing surfacing yog qhov txawv ntawm cov qauv siv vuam, thiab kev txiav txim siab thiab kev saib xyuas ntawm cov kab nrib pleb kuj txawv heev.Kab lus no tshuaj xyuas thiab sib tham txog qhov tshwm sim ntawm cov kab nrib pleb hauv cov txheej txheem ntawm hardfacing hnav-resistant surfacing.

1. Kev txiav txim siab ntawm cov kab nrib pleb

Tam sim no, nyob hauv tsev thiab txawm tias thoob ntiaj teb, tsis muaj cov qauv dav dav rau cov kab nrib pleb tshwm sim los ntawm tawv tawv hnav.Qhov laj thawj tseem ceeb yog tias muaj ntau ntau hom kev ua haujlwm rau cov khoom siv tawv tawv, thiab nws yog qhov nyuaj los txiav txim siab ntau yam Kev Txiav Txim Txhaum Cai raws li cov xwm txheej.Txawm li cas los xij, raws li kev paub dhau los hauv kev siv cov khoom siv tawv tawv-tiv taus vuam hauv ntau qhov chaw, ntau qhov kev tawg tuaj yeem raug txheeb xyuas, nrog rau cov qauv kev lees paub hauv ntau yam lag luam:

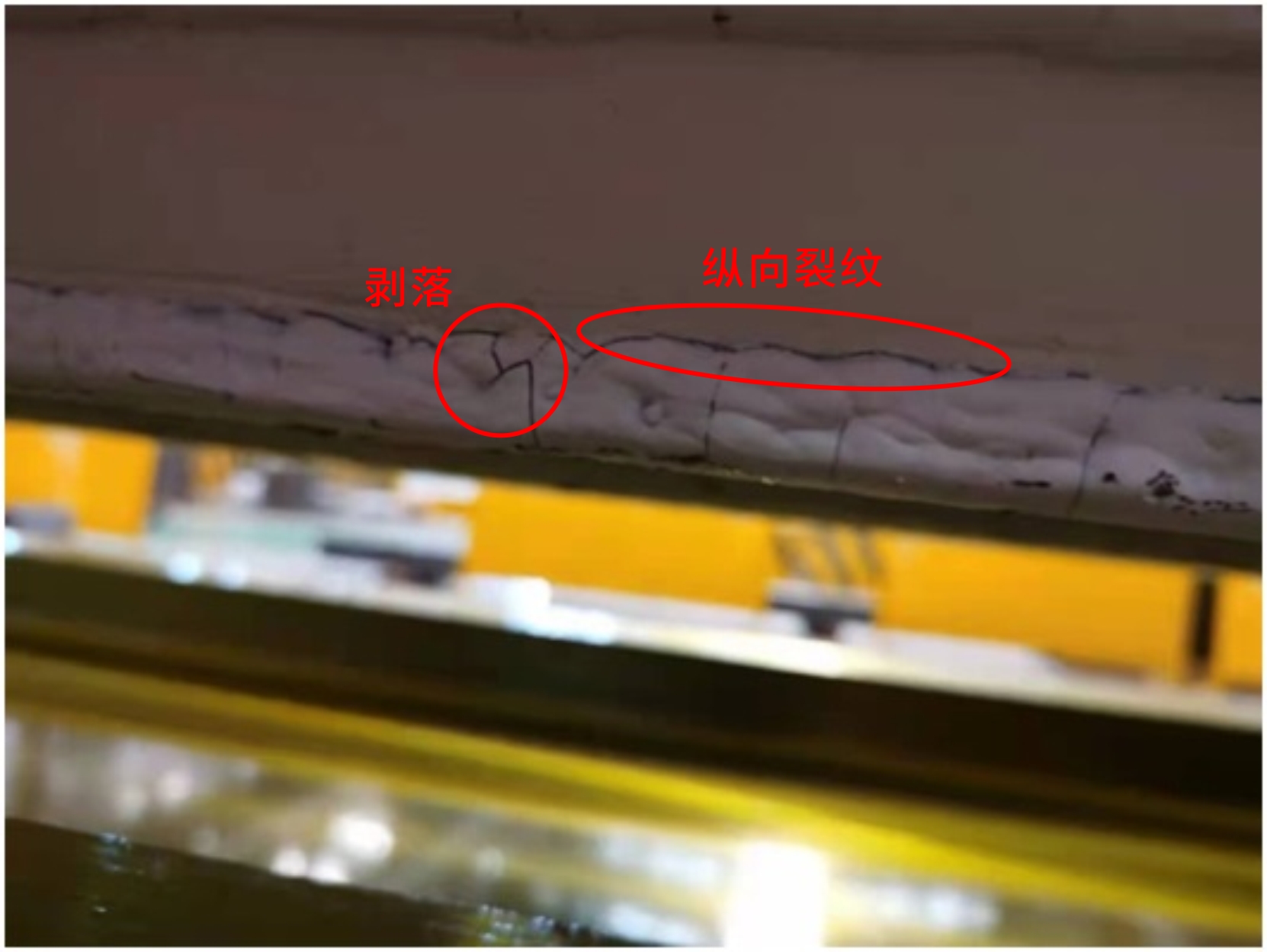

1. Cov kev taw qhia ntawm cov kab nrib pleb yog sib npaug rau cov hlaws weld (longitudinal tawg), nruam transverse tawg, tawg txuas mus rau lub hauv paus hlau, spalling

Ntev npaum li ib qho ntawm cov kab ke saum toj no tau ntsib, muaj kev pheej hmoo tias tag nrho cov txheej saum npoo yuav poob.Yeej, txawm li cas los xij cov khoom thov, nws tsis tuaj yeem lees txais thiab tsuas yog rov ua dua thiab rov ua dua.

2. Tsuas muaj cov kab nrib pleb thiab tsis sib xws

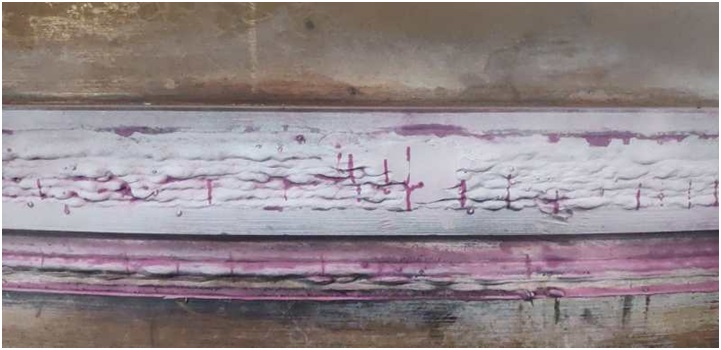

Rau cov khoom ua haujlwm uas muaj kev sib cuag nrog cov khoom siv xws li ore, sandstone, thiab thee mines, hardness yuav tsum siab (HRC 60 lossis ntau dua), thiab cov khoom siv chromium welding feem ntau yog siv rau kev sib tsoo vuam.Cov chromium carbide crystals tsim nyob rau hauv weld hlaws yuav raug tsim vim muaj kev ntxhov siab tso tawm.Cracks tau txais yog tias qhov kev taw qhia tawg tsuas yog perpendicular rau cov hlaws hlaws (transverse) thiab tsis txuas ntxiv.Txawm li cas los xij, tus naj npawb ntawm cov kab nrib pleb tseem yuav raug siv los ua ib qho kev siv los sib piv qhov zoo thiab qhov tsis zoo ntawm cov khoom siv vuam lossis cov txheej txheem surfacing.

3. Tsis muaj cracking weld hlaws

Rau cov khoom ua haujlwm xws li flanges, li qub, thiab cov kav dej, qhov chaw tseem ceeb ntawm cov khoom sib txuas yog cov pa roj thiab cov kua dej, qhov yuav tsum tau ua rau cov kab nrib pleb hauv cov hlaws vuam yog ceev faj ntau dua, thiab feem ntau yuav tsum muaj qhov zoo li ntawm cov hlaws weld yuav tsum tsis txhob muaj cov kab nrib pleb.

Kev tawg me ntsis ntawm qhov chaw ua haujlwm xws li flanges thiab li qub yuav tsum tau kho lossis rov ua haujlwm dua

Siv peb lub tuam txhab GFH-D507Mo valve tshwj xeeb vuam consumables rau surfacing, tsis muaj kab nrib pleb ntawm qhov chaw

2. Lub ntsiab ua rau tawv tawv hnav-resistant surfacing tawg

Muaj ntau yam uas ua rau tawg.Rau cov tawv tawv hnav-resistant surfacing vuam, nws tuaj yeem muab faib ua cov kab tawg kub uas tuaj yeem pom tom qab thawj zaug lossis thib ob dhau, thiab cov kab mob khaub thuas uas tshwm sim tom qab qhov thib ob lossis txawm tias tom qab tag nrho cov vuam.

Kub tawg:

Thaum lub sij hawm vuam txheej txheem, cov hlau nyob rau hauv vuam seam thiab tshav kub-cuam tshuam cheeb tsam txias mus rau high-temperature cheeb tsam ze ntawm lub solidus kab los tsim cov kab nrib pleb.

Cold crack:

Cov kab nrib pleb tsim los ntawm qhov kub thiab txias hauv qab lub solidus (kwv yees ntawm martensitic transformation kub ntawm steel) feem ntau tshwm sim nyob rau hauv nruab nrab-carbon steels thiab high-strength low-alloy steels thiab medium-alloy steels.

Raws li lub npe qhia, cov khoom tawv tawv tau paub txog lawv cov tawv tawv siab.Txawm li cas los xij, kev nrhiav kev nyuaj hauv kev siv tshuab kuj ua rau txo qis hauv plasticity, uas yog, nce hauv brittleness.Feem ntau hais lus, surfacing saum HRC60 tsis tau them nyiaj ntau rau cov thermal tawg tsim thaum lub sij hawm vuam txheej txheem.Txawm li cas los xij, nyuaj surfacing vuam nrog hardness ntawm HRC40-60, yog hais tias yuav tsum tau rau cov kab nrib pleb, Lub intergranular tawg nyob rau hauv lub vuam txheej txheem los yog liquefaction thiab multilateral kab nrib pleb tshwm sim los ntawm lub qaum weld hlaws mus rau lub tshav kub-tshem tawm tsam ntawm lub qis weld. hlaws muaj teeb meem heev.

Txawm hais tias qhov teeb meem ntawm cov kab nrib pleb kub tswj tau zoo, qhov kev hem thawj ntawm cov kab nrib pleb txias tseem yuav raug cuam tshuam tom qab nto welding, tshwj xeeb tshaj yog cov khoom siv tawv tawv xws li tawv tawv weld hlaws, uas yog rhiab rau cov kab nrib pleb txias.Kev tawg hnyav feem ntau yog tshwm sim los ntawm cov kab nrib pleb txias

3. Cov yam tseem ceeb uas cuam tshuam rau kev hnav-tiv taus cov kab nrib pleb ntawm cov tawv tawv thiab cov tswv yim kom tsis txhob tawg

Cov yam tseem ceeb uas tuaj yeem tshawb pom thaum cov kab nrib pleb tshwm sim hauv cov txheej txheem tawv tawv yog raws li hauv qab no, thiab cov tswv yim sib xws tau npaj rau txhua yam los txo qhov kev pheej hmoo ntawm cov kab nrib pleb:

1. Cov khoom siv hauv paus

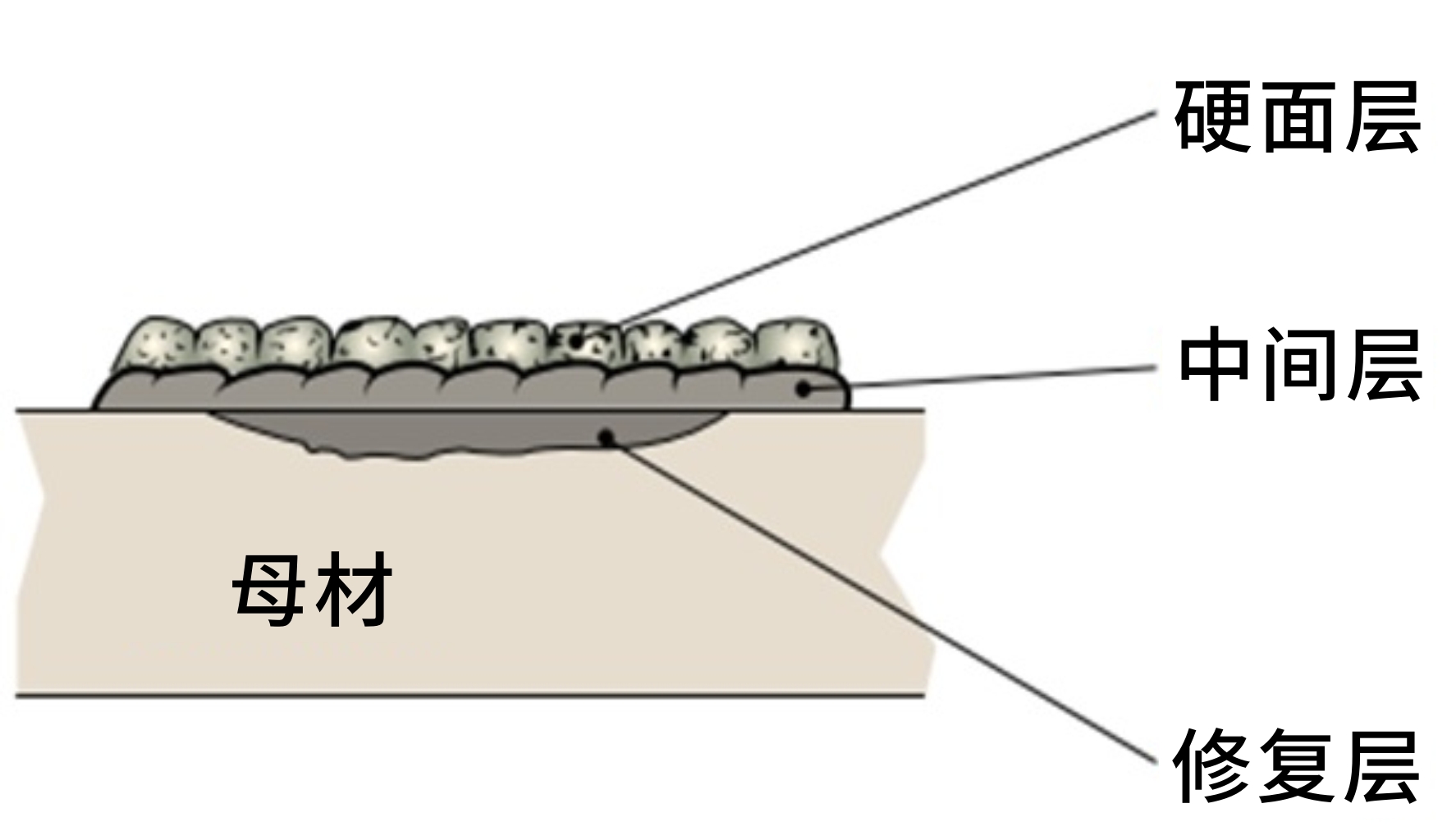

Kev cuam tshuam ntawm lub hauv paus hlau ntawm tawv tawv hnav-resistant surfacing yog ib qho tseem ceeb heev, tshwj xeeb tshaj yog rau cov workpieces nrog tsawg dua 2 txheej ntawm surfacing vuam.Cov muaj pes tsawg leeg ntawm lub hauv paus hlau ncaj qha cuam tshuam rau cov khoom ntawm weld hlaws.Kev xaiv cov khoom siv yog qhov nthuav dav uas yuav tsum tau them sai sai rau ua ntej pib ua haujlwm.Piv txwv li, yog hais tias lub valve workpiece nrog lub hom phiaj hardness ntawm HRC30 yog surfacing nrog ib tug cam khwb cia hlau puag cov ntaub ntawv, nws yog pom zoo kom siv ib tug vuam cov ntaub ntawv uas muaj ib tug me ntsis qis hardness, los yog ntxiv ib tug txheej ntawm stainless hlau intermediate txheej, thiaj li. zam cov pa roj carbon ntsiab lus hauv cov khoom siv los ntawm kev ua kom muaj kev pheej hmoo ntawm cov hlaws hlaws tawg.

Ntxiv ib txheej nruab nrab ntawm cov khoom siv los txo qhov kev pheej hmoo ntawm kev tawg

2. Welding consumables

Rau cov txheej txheem uas yuav tsum tsis txhob muaj cov kab nrib pleb, high-carbon thiab high-chromium vuam consumables tsis haum.Nws raug pom zoo kom siv martensitic system vuam consumables, xws li peb GFH-58.Nws tuaj yeem txuas cov hlaws tsis muaj kab nrib pleb thaum lub hardness siab li HRC58 ~ 60, tshwj xeeb tshaj yog haum rau cov chaw ua haujlwm uas tsis yog-planar uas yog abrasive heev los ntawm cov av thiab pob zeb.

3. Thaum tshav kub kub input

Kev tsim kho ntawm qhov chaw nyiam siv ntau dua tam sim no thiab qhov hluav taws xob vim qhov tseem ceeb ntawm kev ua haujlwm, tab sis kev txo qis tam sim no thiab qhov hluav taws xob kuj tuaj yeem txo qhov tshwm sim ntawm thermal tawg.

4. Kev tswj qhov kub thiab txias

Multi-layer thiab multi-pass hardfacing welding tuaj yeem suav hais tias yog cov txheej txheem ntawm cov cua kub tsis tu ncua, txias thiab rov ua dua rau txhua qhov dhau, yog li kev tswj qhov kub thiab txias yog qhov tseem ceeb heev, los ntawm preheating ua ntej vuam kom dhau qhov kub ntawm qhov chaw tswj, thiab txawm tias cov txheej txheem txias tom qab. welding, xav tau kev saib xyuas zoo.

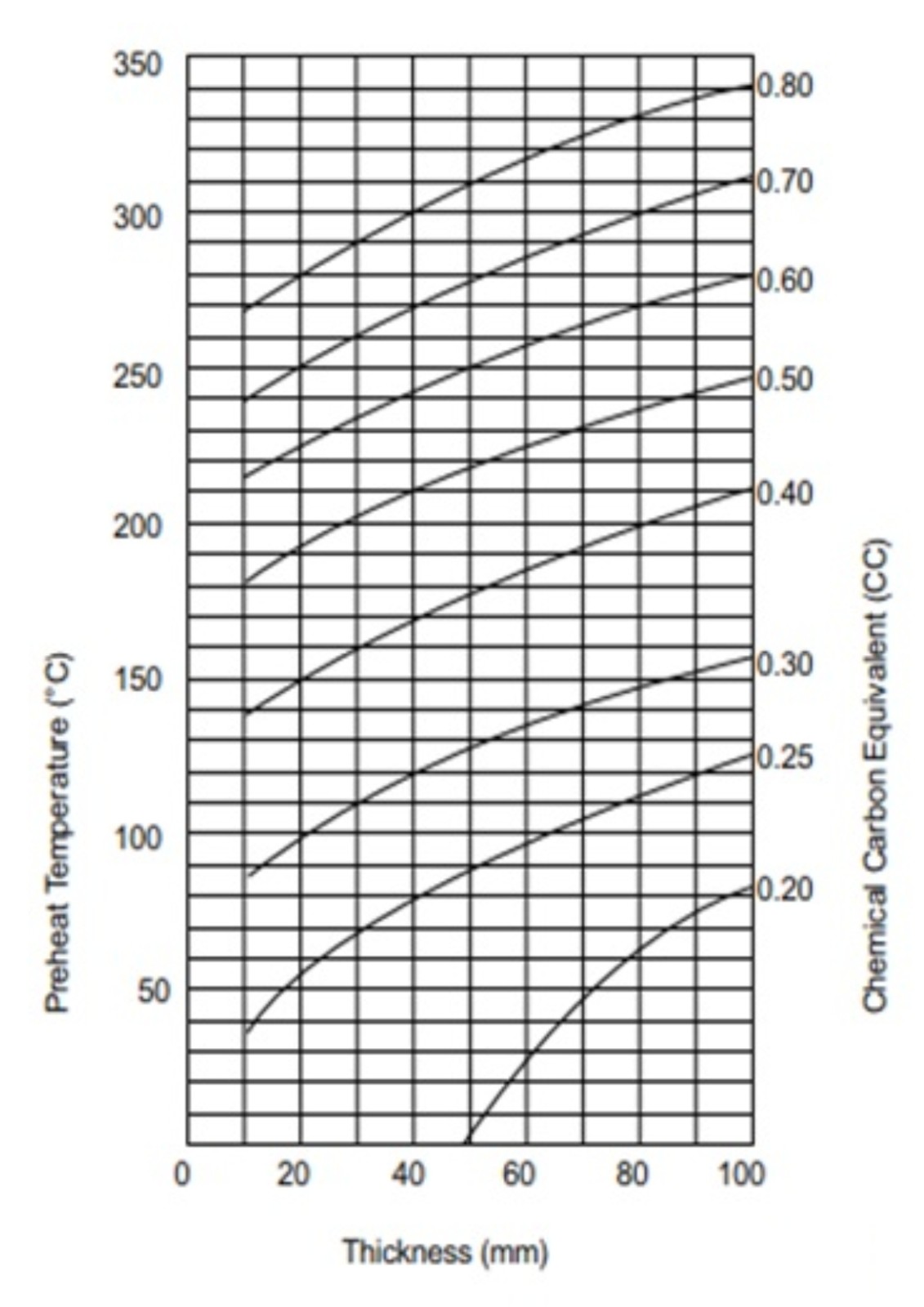

Lub preheating thiab khiav qhov kub thiab txias ntawm surfacing vuam yog ze ze rau cov ntsiab lus carbon ntawm lub substrate.Lub substrate no suav nrog cov khoom siv hauv paus lossis txheej nruab nrab, thiab hauv qab ntawm qhov tawv tawv.Feem ntau hais lus, vim yog cov ntsiab lus carbon ntawm cov tawv tawv deposited hlau Yog tias cov ntsiab lus siab, nws raug nquahu kom tswj txoj kev kub siab tshaj 200 degrees.Txawm li cas los xij, hauv kev ua haujlwm tiag tiag, vim qhov ntev ntawm cov hlaws hlaws, lub hauv ntej ntawm cov hlaws hlaws tau txias los ntawm qhov kawg ntawm ib qho dhau, thiab qhov thib ob hla yuav yooj yim tsim cov kab nrib pleb hauv thaj chaw tshav kub ntawm lub substrate. .Yog li ntawd, thaum tsis muaj cov cuab yeej tsim nyog los tswj qhov kub thiab txias ua ntej welding, nws raug nquahu kom ua haujlwm hauv ntau ntu, welds luv luv, thiab txuas txuas txuas txuas txuas rau hauv tib seem kom tswj tau qhov ntsuas kub.

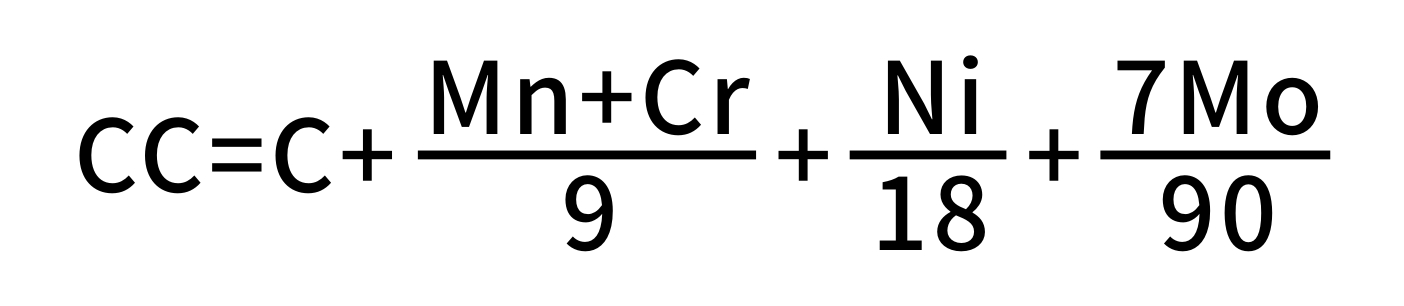

Kev sib raug zoo ntawm cov ntsiab lus carbon thiab preheating kub

Kev ua kom txias qeeb tom qab ntog kuj yog ib qho tseem ceeb heev tab sis feem ntau tsis quav ntsej cov kauj ruam, tshwj xeeb tshaj yog rau cov khoom loj.Qee lub sij hawm nws tsis yooj yim kom muaj cov cuab yeej tsim nyog los muab cov cua txias qeeb.Yog tias tsis muaj txoj hauv kev los daws qhov teeb meem no tiag tiag, peb tsuas yog pom zoo kom siv nws dua Cov txheej txheem ntawm kev ua haujlwm segmented, lossis tsis txhob hla qhov vuam thaum qhov kub thiab txias, kom txo qhov kev pheej hmoo ntawm cov kab mob khaub thuas.

Plaub.Xaus

Tseem muaj ntau tus neeg tsim khoom sib txawv ntawm qhov yuav tsum tau ua ntawm hardfacing rau cov kab nrib pleb hauv kev siv tswv yim.Kab lus no tsuas yog ua rau kev sib tham ntxhib raws li kev paub dhau los.Peb lub tuam txhab cov tawv tawv hnav-resistant series ntawm vuam consumables muaj cov khoom siv rau cov neeg siv khoom xaiv rau ntau yam hardness thiab daim ntaub ntawv.Zoo siab txais tos los tham nrog cov lag luam hauv txhua cheeb tsam.

Daim ntawv thov ntawm hnav-resistant composite board Hoobkas

| Yam khoom | Tiv thaiv roj | qhov loj | Main | HRC | Siv |

| GFH-61-0 | Kev tiv thaiv tus kheej | 1.6 2.8 3.2 | c:5.0 ua ib: 0.6 Mn: 1.2 Cr: 28.0 Nws | 61 | Haum rau kev sib tsoo log, cement mixers, bulldozers, thiab lwm yam. |

| GFH-65-0 | Kev tiv thaiv tus kheej | 1.6 2.8 3.2 | c:5.0 ua Cr: 22.5 Nws Mo: 3.2 V: 1.1 wb: 1.3 ib: 3.5 | 65 | Haum rau kev kub hnyiab plua plav tshem tawm kiv cua, blast furnace feeding khoom, thiab lwm yam. |

| GFH-70-O | Kev tiv thaiv tus kheej | 1.6 2.8 3.2 | c:5.0 ua Cr: 30.0 Nws ib: 0.3 | 68 | Muaj feem xyuam rau cov menyuam yaus, dab liab, tau txais iav, moj tej tawg coal npog, grinder, thiab lwm yam. |

Kev siv hauv kev lag luam cement

| Yam khoom | Tiv thaiv roj | qhov loj | Main | HRC | Siv |

| GFH-61-0 | Kev tiv thaiv tus kheej | 1.6 2.8 3.2 | c:5.0 ua ib: 0.6 Mn: 1.2 Cr: 28.0 Nws | 61 | Haum rau kev sib tsoo pob zeb rollers, cement mixers, thiab lwm yam |

| GFH-65-0 | Kev tiv thaiv tus kheej | 1.6 2.8 3.2 | c:5.0 ua Cr: 22.5 Nws Mo: 3.2 V: 1.1 wb: 1.3 ib: 3.5 | 65 | Haum rau kev kub hnyiab plua plav tshem tawm kiv cua, blast furnace feeding khoom, thiab lwm yam. |

| GFH-70-O | Kev tiv thaiv tus kheej | 1.6 2.8 3.2 | c:5.0 ua Cr: 30.0 Nws ib: 0.3 | 68 | Haum rau kev sib tsoo pob zeb chais, dab hniav, txais cov hniav, grinders, thiab lwm yam. |

| GFH-31-S | TXX-81 | 2.8 3.2 | C: 0.12 ib: 0.87 Mn: 2.6 ib: 0,53 | 36 | Muaj feem xyuam rau cov khoom siv hlau-rau-hlau xws li cov yas yas thiab cov axles |

| GFH-17-S | TXX-81 | 2.8 3.2 | c:0.09 ua ib: 0.42 Mn: 2.1 Cr: 2.8 ib: 0.43 | 38 | Muaj feem xyuam rau cov khoom siv hlau-rau-hlau xws li cov yas yas thiab cov axles |

Daim ntawv thov cog steel

| Yam khoom | Tiv thaiv roj | qhov loj | Main | HRC | Siv |

| GFH-61-0 | Kev tiv thaiv tus kheej | 1.6 2.8 3.2 | c:5.0 ua ib: 0.6 Mn: 1.2 Cr: 28.0 Nws | 61 | Haum rau sintering cog rauv bar, dab hniav, hnav-resistant daim hlau, thiab lwm yam. |

| GFH-65-0 | Kev tiv thaiv tus kheej | 1.6 2.8 3.2 | c:5.0 ua Cr: 22.5 Nws Mo: 3.2 V: 1.1 wb: 1,368 ib: 3.5 | 65 | |

| HWM-70-0 | Kev tiv thaiv tus kheej | 1.6 2.8 3.2 | c:5.0 ua Cr: 30.0 Nws ib: 0.3 | 68 | |

| GFH-420-S | TXX-81 | 2.8 3.2 | c:0.24 ib: 0.65 Mn: 1.1 Ib: 13.2 | 52 | Haum rau casting rolls, conveying rolls, steering rolls, thiab lwm yam nyob rau hauv nruam casting nroj tsuag thiab kub dov nroj tsuag |

| GFH-423-S | TXX-82 | 2.8 3.2 | C: 0.12 ib: 0.42 Mn: 1.1 Ib: 13.4 Mo: 1.1 v:0.16 ib: 0.15 | 45 | |

| GFH-12-S | TXX-81 | 2.8 3.2 | C: 0.25 ib: 0.45 Mn: 2.0 Nws ib: 5.8 ib: 0.8 v:0, 3 wb: 0.6 | 51 | Anti-adhesive hnav cov khoom, haum rau steel phaj Hoobkas steering yob, pinch yob thiab hnav qhov nruab nrab ntawm cov hlau |

| GFH-52-S | TXX-81 | 2.8 3.2 | c:0.36 ib: 0.64 Mn: 2.0 Nws ib: 2.9 ib: 6.2 Mo: 1.35 Nws v: 0.49 | 52 |

Kev thov Miner

| Yam khoom | Tiv thaiv roj | qhov loj | Main | HRC | Siv |

| GFH-61-0 | Kev tiv thaiv tus kheej | 1.6 2.8 3.2 | c:5.0 ua ib: 0.6 Mn: 1.2 Cr: 28.0 Nws | 61 | Muaj feem xyuam rau excavators, roadheaders, picks, thiab lwm yam. |

| HWM-58 | CO2 | 1.6 2.4 | c:0,5 ua ib: 0.5 m:0,95 ua ib: 0.03 ib: 5.8 ib: 0.6 | 58 | Haum rau surfacing vuam nyob rau sab ntawm lub pob zeb xa trough |

| HWM-45 | CO2 | 1.6 2.4 | C: 2.2 ib: 1.7 mn:0,9 ua Cr: 11.0 Nws ib: 0,46 | 46 | Haum rau hnav qhov nruab nrab ntawm cov hlau |

Daim ntawv thov Valve

| Yam khoom | Tiv thaiv roj | qhov loj | Main | HRC | Siv |

| GFH-D507 | CO2 | 1.6 2.4 | C: 0.12 S: 0.45 Nws Mn: 0.4 ib: 0.1 Cr: 13 Mo: 0.01 Nws | 40 | Haum rau surfacing vuam ntawm valve sealing nto |

| GFH-D507Mo | CO2 | 1.6 2.4 | C: 0.12 S: 0.45 Nws Mn: 0.4 ib: 0.1 Cr: 13 Mo: 0.01 Nws | 58 | Haum rau surfacing vuam ntawm li qub nrog siab corrosiveness |

| GFH-D547Mo | Phau ntawv rods | 2.6 3.2 4.0 5.0 | c:0.05 ua Mn: 1.4 ib: 5.2 p: 027 S: 0.007 Nws ib: 8.1 Ib: 16.1 ib: 3.8 ib: 0.61 | 46 | Haum rau kev kub siab, siab siab valve surfacing vuam |

More information send to E-mail: export@welding-honest.com

Post lub sij hawm: Dec-26-2022