I. Txheej txheem cej luam

Nrog rau txoj kev loj hlob sai ntawm kev lag luam kev lag luam, cov khoom siv welded xws li niaj hnub engineering thiab cov hlab ntsha siab tau txhim kho mus rau qhov loj thiab sib zog.Cov kev xav tau rau cov qib steel zog tau nce siab dua thiab siab dua, tsis tsuas yog xav tau cov khoom siv kho tshuab zoo xwb, tab sis kuj tseem ua tau zoo, weldability thiab tawg tsis kam.

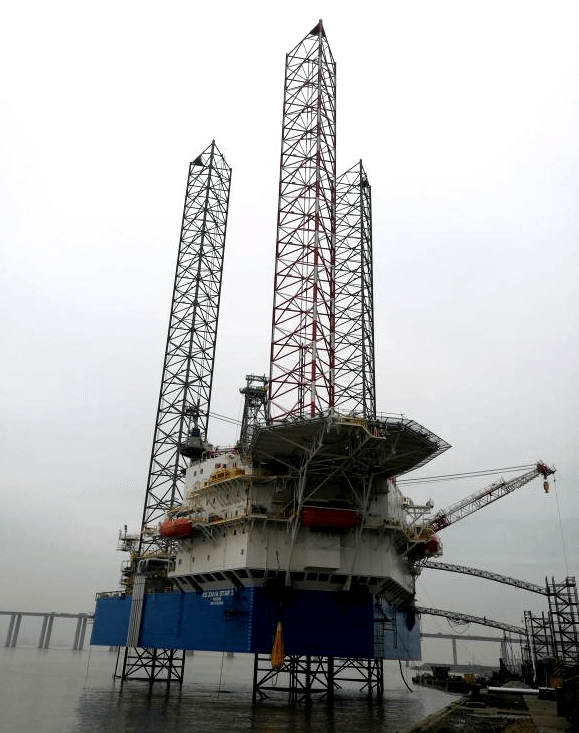

Q690 steel belongs rau high-strength welded structural steel, qhov twg Q stands rau yield, thiab 690 txhais tau tias lub zog yield theem yog 690MPa.690MPa qib steel muaj siab yield thiab tensile lub zog, thiab yog dav siv nyob rau hauv thee mining machinery, siv machinery, marine engineering, offshore platforms, siab hlab ntsha, thiab lwm yam., yuav tsum tau steel kom muaj siab yield zog thiab qaug zog txwv, zoo cuam tshuam toughness, Txias. formability thiab weldability zoo heev.

2.Kev qhia luv luv ntawm Q690 steel phaj

| Thoob ntiaj teb Q690 steel qib | qw 690a | q690 ib | qw 690c | qw 690d | qw 690e | qw 690f |

| Plaub | Kub dov | Quenching + tempering (quenched thiab tempered xeev) | ||||

| Cov ntsiab lus impurity | Siab dua P/S | qis P/S | Yam tsawg kawg nkaus P/S | |||

| Kev xav tau kev poob siab | NO | Qhov kub thiab txias poob siab | 0 ℃ | -20 ℃ | -40 ℃ | -60 ℃ |

Txawm li cas los xij, tam sim no, 690MPa steel phaj rau cov hlab ntsha siab hauv tsev feem ntau yog raws li European tus qauv EN10028-6, thiab cov khoom muaj feem cuam tshuam tau luv luv hauv cov lus hauv qab no:

| Yield 690MPA steel rau European cov khoom siv siab | p690 qw | p690 qw | p69 qw 1 | p69 qw 2 |

| Plaub | zoo grain quenched thiab tempered steel | |||

| zog xav tau | Yield ≥690MPa (phaj thickness≤50mm) Tensile770-940MPa | |||

| Cov ntsiab lus impurity | P≤0.025%, S≤0.015% | P≤0.02%, S≤0.010% | ||

| Kev xav tau kev poob siab | 20 ℃ ≥ 60 J | 20 ℃ ≥ 60 J | 0 ℃ ≥ 60 J | -20 ℃ ≥40J |

| 0 ℃ ≥40J | 0 ℃ ≥40J | -20 ℃ ≥40J | -40 ℃ ≥ 27 J | |

| -20 ℃ ≥ 27 J | -20 ℃ ≥ 27 J | -40 ℃ ≥ 27 J | -60 ℃ ≥ 27 J | |

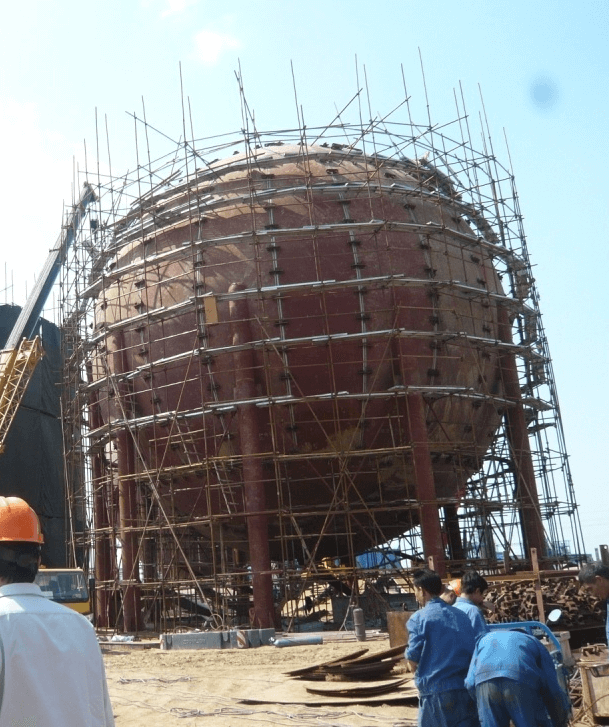

| Cov chaw siv tseem ceeb | Cov txheej txheem siab-cov kabmob lossis cov hlab ntsha siab uas tsis tshua muaj kev cuam tshuam toughness | Spherical tank nrog cov txheej txheem siab | Liquefied gas marine kua tank | |

Raws li cov phaj steel rau cov tso tsheb hlau luam thiab lub peev xwm siab, nws yuav tsum muaj lub zog zoo thiab lub zog, kev ua haujlwm txias txias thiab tsis tshua muaj kev tawg.Txawm hais tias cov quenched thiab tempered Q690 steel muaj qis dua carbon sib npaug thiab cov khoom zoo heev, nws tseem muaj qee yam tawv tawv piv nrog rau lwm yam 50/60kg siab nkoj steels, thiab tom qab vuam cua sov yuav tsum tau kho.Txawm li cas los xij, ntau qhov kev sim kev tshawb fawb tau pom tias rau Q690 steel vuam consumables, qhov qis-kub qhov cuam tshuam toughness yuav ua rau tsis zoo tom qab kev ntxhov siab kho cua sov, thiab nrog rau qhov nce ntawm kev kho cua sov thiab txo qhov cuam tshuam qhov kub, qhov deterioration. ntawm welding consumable toughness yuav pom tseeb dua.Yog li ntawd, nws yog qhov tseem ceeb tshaj plaws los tsim kom muaj lub zog siab, muaj kev cuam tshuam loj, thiab cov khoom siv hluav taws xob kho cua sov rau Q690 steel kom ua tiav Q690 steel rau cov cuab yeej siv siab, txo cov khoom siv hlau, thiab txo cov nqi tsim khoom.

3.Kev qhia luv luv ntawm peb Q690 steel vuam pas nrig

| Yam khoom | Txuj | Hom tawv nqaij | Polarity | cov yam ntxwv tseem ceeb |

| GEL-118M | AWS A5.5 E1108MISO 18275-BE7618-N4M2A | Hlau hmoov tsis tshua muaj hydrogen hom | DC + / AC | Lub zog muaj zog, tsis tshua muaj hydrogen, siab deposition efficiency, ruaj khov mechanical zog, zoo heev tsis tshua muaj kub cuam tshuam toughness ntawm -50 ° C, thiab zoo cuam tshuam toughness ntawm -40 ° C tom qab kev kho cua sov |

| GEL-758 | AWS A5.5 E11018-GISO 18275-BE7618-G A | Hlau hmoov tsis tshua muaj hydrogen hom | DC + / AC | Ultra-low hydrogen, siab deposition efficiency, siab toughness (-60 ℃ ≥70J), zoo cuam tshuam toughness ntawm -40 / -50 ℃ tom qab kho cua sov |

| GEL-756 | AWS A5.5 E11016-GISO 18275-BE7616-G A | Tsawg hydrogen potassium hom | AC / DC + | Ultra-low hydrogen, AC / DC + dual-lub hom phiaj, muaj kev cuam tshuam siab toughness (-60 ℃ ≥70J), zoo cuam tshuam toughness ntawm -50 / -60 ℃ tom qab kev kho cua sov |

4.Q690 steel vuam pas nrig txhua yam kev ua tau zoo

| Yam khoom | Raws li-welded mechanical zog | ||||||

| Yield MPA | Tensile MPA | Txuas ntxiv % | Cov cuab yeej cuam tshuam J / ℃ | Kev kuaj hluav taws xob | Diffusible hydrogen ml / 100 g | ||

| -50 ℃ | -60 ℃ | ||||||

| AWS A5.5 E11018M | 680- 760 ib | ≥760 | ≥ 20 | ≥ 27 | - | I | - |

| ISO 18275-B E7618-N4M2A | 680- 760 ib | ≥760 | ≥18 | ≥ 27 | - | I | - |

| GEL-118M | 750 | 8 30 | 21.5 ib | 67 | 53 | I | 3.2 |

| AWS A5.5 E1101X-G | ≥670 | ≥760 | ≥15 | - | - | I | - |

| ISO 18275B E761X-GA | ≥670 | ≥760 | ≥13 | - | - | I | - |

| GEL-758 | 751 ib | 817 ib | 19.0 Nws | 90 | 77 | I | 3.4 |

| GEL-756 | 764 ib | 822 ib | 19.0 Nws | 95 | 85 | I | 3.6 |

Piv txwv:

1. Cov "X" cim hauv cov ntawv liab hauv American Standard thiab European Standard sawv cev rau hom tshuaj tawv nqaij.

2. GEL-758 sib haum rau E11018-G thiab ISO 18275-B E7618-G A hauv AWS thiab ISO cov qauv raws li.

3. GEL-756 sib raug rau E11016-G thiab ISO 18275-B E7616-G A hauv AWS thiab ISO cov qauv raws.

Cov khoom siv ntawm Q690 steel vuam pas nrig hauv kev kho cua sov

| Yam khoom | Mechanical zog ntawm tshav kub kho lub xeev | ||||||

| Yield MPA | Tensile MPA | Txuas ntxiv % | Cov cuab yeej cuam tshuam J / ℃ | Cua sov ℃ * h | |||

| -40 ℃ | -50 ℃ | -60 ℃ | |||||

| Lub hom phiaj project | ≥670 | ≥760 | ≥15 | ≥60 | ≥52 | ≥47 | 570 * 2 |

| GEL-118M | 751 ib | 827 ib | 22.0 Nws | 85 | 57 | - | 570 * 2 |

| GEL-758 | 741 ib | 839 ib | 20.0 Nws | 82 | 66 | 43 | 570 * 2 |

| GEL-756 | 743 ib | 811 ib | 21.5 ib | 91 | 84 | 75 | 570 * 2 |

Piv txwv:

1. AWS thiab ISO cov qauv muaj feem xyuam tsis muaj kev kho cua sov rau cov khoom siv saum toj no.Cov kev kho cua sov saum toj no tau sau tseg raws li cov txheej txheem ntawm cov neeg siv khoom feem ntau thiab tsuas yog siv rau kev siv xwb.

2. GEL-118M muaj kev cuam tshuam zoo heev ntawm -40 ° C tom qab kev kho cua sov, thiab qhov cuam tshuam tsis zoo ntawm -50 ° C yog pom tseeb dua.

3. Tom qab kev kho cua sov, GEL-758 muaj kev cuam tshuam zoo heev ntawm -40 ° C, zoo cuam tshuam toughness ntawm -50 ° C, thiab pom tseeb deterioration ntawm qis kub ntawm -60 ° C.

4. Qhov ntsuas kub tsis tshua muaj kev cuam tshuam toughness deterioration ntawm GEL-756 tom qab kev kho cua sov yog qhov me me, thiab qhov kub thiab txias toughness ntawm -60 ° C tseem zoo.

Weldability ua qauv qhia ntawm Q690 steel vuam pas nrig

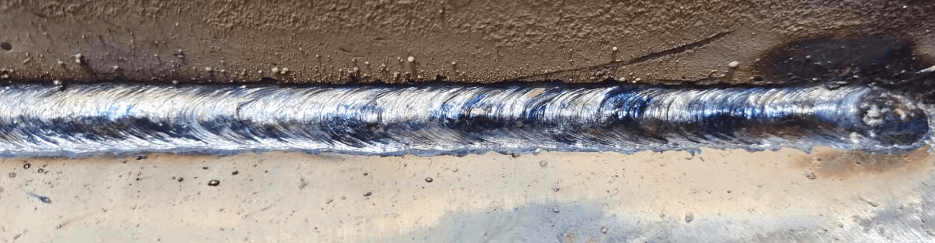

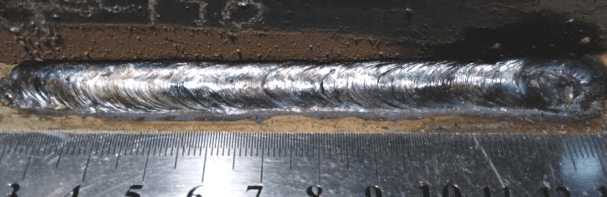

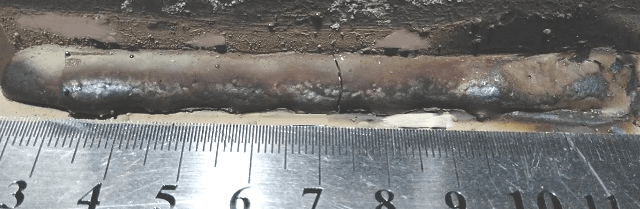

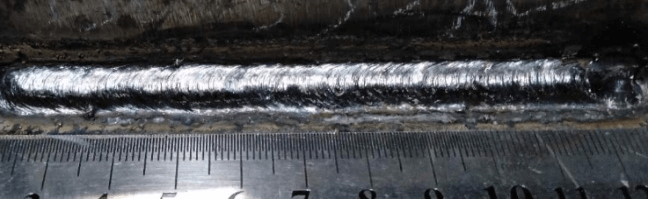

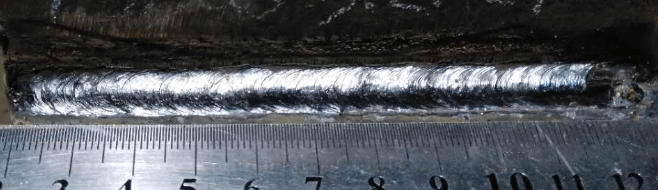

GEL-118M ca fillet vuam ua ntej thiab tom qab slag tshem tawm (DC +)

Ua ntej thiab tom qab GEL-758 ca fillet vuam slag tshem tawm (DC +)

GEL-756 ca fillet vuam ua ntej thiab tom qab slag tshem tawm (AC)

GEL-756 ca fillet vuam ua ntej thiab tom qab slag tshem tawm (DC +))

Q690 steel vuam pas nrig vuam ceev faj

1. Cia cov khoom siv welding:

Welding consumables raug pom zoo kom muab khaws cia nyob rau hauv qhov kub thiab txias tsis tu ncua, thiab muab tso rau ntawm pallets lossis rhawv, tsis txhob sib cuag nrog cov phab ntsa thiab hauv av.

2. Kev npaj ua ntej vuam:

Ua tib zoo tshem tawm cov dej noo, xeb, roj stains, thiab lwm yam rau ntawm qhov chaw ntawm cov khoom siv hauv paus, thiab tsis txhob ntub dej los yog raug los nag thiab daus.

3. Windproof ntsuas:

Thaum vuam, nws yuav tsum xyuas kom meej tias qhov siab tshaj plaws cua ceev ntawm qhov chaw vuam tsis pub tshaj 2m / s.Txwv tsis pub, kev tiv thaiv yuav tsum tau ua.

4. Preheating:

Nws raug nquahu kom siv cov khoom siv hluav taws xob cua sov kom sov lub workpiece kom siab tshaj 150 ° C ua ntej vuam.Txawm tias ua ntej tack vuam, nws yuav tsum tau preheated rau saum 150 ° C.

5. Txheej thiab txoj kev kub tswj:

Thaum lub sij hawm tag nrho cov txheej txheem vuam, qhov sib cuam tshuam qhov kub yuav tsum tsis txhob qis dua qhov kub thiab txias, thiab qhov pom zoo dhau qhov kub yog 150-220 ° C.

6. Hydrogen tshem tawm tom qab vuam:

Tom qab lub vuam seam yog welded, tam sim ntawd nce qhov kub ntawm hluav taws xob cua sov mus rau 250 ℃ ~ 300 ℃, cia nws sov li 2 mus rau 4 teev, thiab ces txias maj mam.

① Yog hais tias lub thickness ntawm lub workpiece yog ≥50 hli, lub sij hawm tuav yuav tsum tau ncua mus rau 4-6 teev, thiab ces txias maj mam.

② Nyob rau hauv cov xwm txheej ntawm cov tuab loj thiab kev txwv loj, ib qho ntxiv dehydrogenation tuaj yeem ntxiv tom qab vuam mus rau 1/2 thickness, thiab maj mam txias rau qhov kub thiab txias.

7. Pem teb layout:

Nws raug nquahu kom siv cov txheej txheem ntau txheej thiab ntau dhau vuam, thiab qhov vuam ceev yuav tsum tau ceev ceev.

More information send to E-mail: export@welding-honest.com

Post lub sij hawm: Jan-10-2023