I. Txheej txheem cej luam

Nrog rau txoj kev loj hlob sai ntawm thoob ntiaj teb tshuaj thiab lub zog logistics, stainless hlau cia tank thiab ntim tau dav siv nyob rau hauv kev thauj mus los thiab cia cov tshuaj, khoom noj khoom haus thiab dej haus, lub zog thiab lwm yam ntaub ntawv.Vim nws zoo heev uas tsis muaj kub toughness thiab zoo corrosion kuj, austenitic stainless hlau yog dav siv nyob rau hauv kev tsim kho ntawm cryogenic cia tso tsheb hlau luam, khoom siv thiab loj cryogenic lug.

Cryogenic cia tank

2.Kev taw qhia luv luv ntawm peb -196 ℃ qis kub cuam tshuam stainless hlau vuam consumables

| Qeb | Lub npe | Qauv | Txuj | Lus ceeb toom | |

| GB/YB | AWS | ||||

| Hluav taws xob | GES-308 LT | A002 | E308L-16 | E308L-16 | -196 ℃ ≥31J |

| Flux kab | GFS-308 LWM | - | TS 308L-F C11 | E308LT1-1 | -196 ℃ ≥34J |

| Khoom hlau | GTS-308 LT (TIG) | - | H022Cr21Ni10 | TSI 308L | -196 ℃ ≥34J |

| GMS-308 LWM (MIG) | - | H022Cr21Ni10 | TSI 308L | -196 ℃ ≥34J | |

| SAW | GWS-308/ GXS-300 | - | S F308L FB-S308L | TSI 308L | -196 ℃ ≥34J |

3.Our electrode GES-308LT (E308L-16)

Txhawm rau ua kom tau raws li kev xav tau ntawm kev lag luam, peb lub tuam txhab tau tsim ntau yam ntawm qhov kub thiab txias, siab toughness austenitic stainless hlau electrodes, cov tshuaj muaj pes tsawg leeg ntawm cov hlau deposited (raws li qhia nyob rau hauv Table 1) thiab ruaj khov mechanical zog (raws li qhia nyob rau hauv Table 2), thiab muaj cov txheej txheem vuam zoo tag nrho, thiab zoo heev uas tsis muaj qhov kub thiab txias, qhov cuam tshuam ntawm nws cov nyiaj ferrite ntawm qhov cuam tshuam tus nqi (Table 3).

1.Chemical muaj pes tsawg leeg ntawm deposited hlau

| E308L-16 | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | N | Fn |

| NB (%) | 0.04 ib | 0.5-2.5 hli | 1.0 | 0.030 Nws | 0.020 ib | 9.0-12.0 Nws | 18.0-21.0 Nws | 0.75 ib | 0.75 ib | - | - |

| Qauv 1 | 0.022 ib | 1.57 ib | 0.62 ib | 0.015 ib | 0.006 ib | 10.25 Nws | 19.23 Nws | 0.020 ib | 0.027 ib | 0.046 ib | 6.5 |

| Qauv 2 | 0.037 ib | 2.15 | 0.46 ib | 0.018 ib | 0.005 ib | 10.44 Nws | 19.19 Nws | 0.013 ib | 0.025 ib | 0.45 ib | 3.8 |

| Qauv 3 | 0.032 ib | 1.37 ib | 0.49 ib | 0.017 ib | 0.007 ib | 11.79 Nws | 18.66 Nws | 0.021 ib | 0.027 ib | 0.048 ib | 0.6 |

Table 1

2.Mechanical zog ntawm deposited hlau

| E308L-16 | Yield MPa | Tensile MPa | Elongation % | -196℃kev cuam tshuam J /℃ | GB / T4334-2020 E Intergranular corrosion | RKev tshuaj ntsuam adiographic | Lus ceeb toom | |

| Ib tus nqi | Tus nqi nruab nrab | |||||||

| NB | - | 510 | 30 | - | - | - | I | - |

| Qauv 1 | 451 ib | 576 ib | 42 | 32/32/33 ib | 32.3 | tsim nyog | I | - |

| Qauv 2 | 436 ib | 563 ib | 44 | 39/41/39 ib | 39.7 ib | tsim nyog | I | - |

| Qauv 3 | 412 | 529 ib | 44.5 ib | 52/53/55 ib | 53.3 ib | tsim nyog | I | - |

Rooj 2

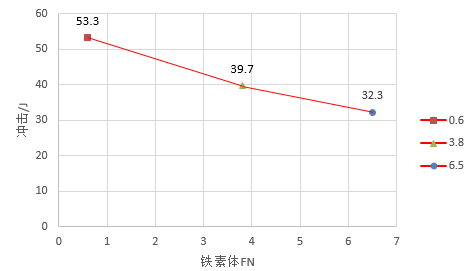

3.Qhov cuam tshuam ntawm cov nyiaj tso tawm hlau ferrite rau qhov cuam tshuam

4.Display ntawm vuam txheej txheem (φ3.2mm)

Upright vuam ua ntej thiab tom qab tshem tawm slag (DC +)

Pipeline vuam ua ntej thiab tom qab tshem tawm slag (DC +)

4. Kev ceev faj rau kev vuam ntsug

1. Tsawg tam sim no vuam yuav tsum tau siv;

2. Khaws lub arc kom tsawg li sai tau;

3. Thaum lub arc swings mus rau ob sab ntawm qhov zawj, nres ib pliag, thiab lub viav vias dav yog tswj tsis pub dhau 3 npaug ntawm txoj kab uas hla ntawm electrode.

5.Pipeline daim duab ntawm vuam consumables daim ntawv thov

Rau -196 ℃ qis-kub tsis zoo stainless hlau vuam consumables, tom qab xyoo ntawm kev tshawb fawb thiab kev loj hlob ntawm vuam consumables, peb twb muaj kev txhawb nqa vuam consumables rau vuam rods, khoom cores, flux cores thiab submerged arcs, thiab tau tsim tes electrode nruam arc. welding consumables rau tag nrho-txoj hauj lwm vuam, thiab muaj ntau yam engineering daim ntawv thov ua tiav, txais tos cov neeg muas zaub los sab laj thiab xaiv!

Post lub sij hawm: Dec-16-2022