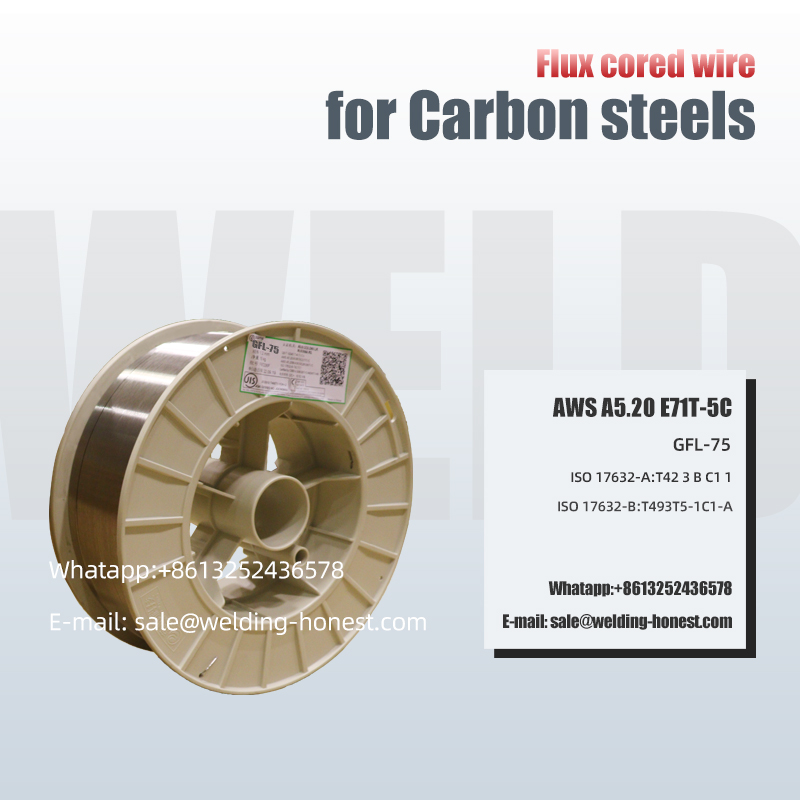

High Carbon steels Flux cored hlau E70T-4 weld fabrication jointing

Daim ntawv thov

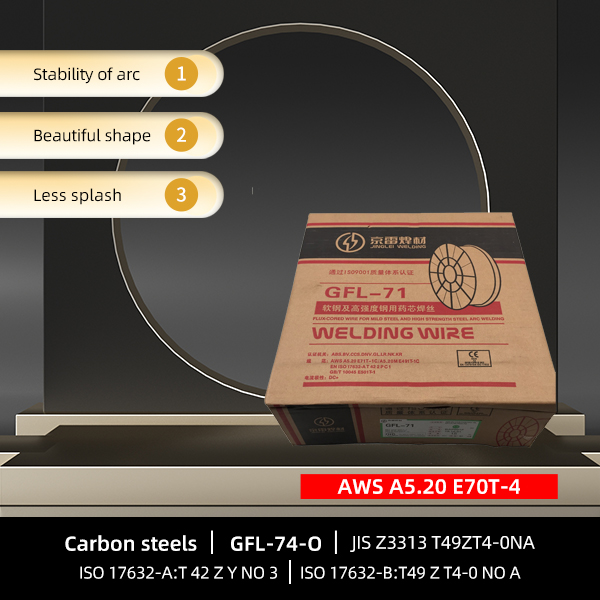

Haum rau lub tsev qauv, steel ncej thiab lwm yam steel qauv pob tw vuam thiab fillet vuam.

GB/T10045 T 49 Z T4-0 NA, AWS A5.20 E70T-4 & A5.20M E490T-4, ISO17632-A:T42 ZY NO 3, ISO 17632-B:T49 Z-0 NO A,JIS Z3313 T49ZT4-0NA.

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | AI |

| GB/T RULES | 0.30 Nws | 2.00 Nws | 0.90 ib | 0.20 ib | 0.50 ib | 0.30 Nws | 0.030 Nws | 0.030 Nws | 2.00 Nws |

| AWS RULES | 0.30 Nws | 1.75 ib | 0.30 Nws | 0.20 ib | 0.50 ib | 0.30 Nws | 0.030 Nws | 0.030 Nws | 1.80 ib |

| EXAMPLE VALUE | 0.220 Nws | 0.550 Nws | 0.30 Nws | 0.03 ib | 0.02 ib | 0.01 ib | 0.013 ib | 0.002 ib | 1.5 |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 390 | 490-670 : kuv | AW | - | 18 | ||||

| AWS RULES | 390 | 490-670 : kuv | AW | - | 22 | ||||

| EXAMPLE VALUE | 430 | 590 ua | AW | - | 25 | ||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.4 | 2.8 | 3 | ||||

| VOLT | 24-32 : kuv | 24-35 : kuv | 24-35 : kuv | ||||

| AMP | 260-400 Nws | 280-450 : kuv | 280-450 : kuv | ||||

| LENGTH: MM | 65-70 : kuv | 65-70 : kuv | 90-95 : kuv |

Peculiarity

Nyob rau hauv cov xwm txheej ntawm lub hauv paus hlau xeb, oxidation thiab siab sulfur ntsiab lus.

Kev siv tau zoo porosity kuj.

Vuam dhau txoj kev zoo nkauj, zoo slag tshem tawm.

Qhia kom meej

Zoo desquamation

Cov duab zoo nkauj

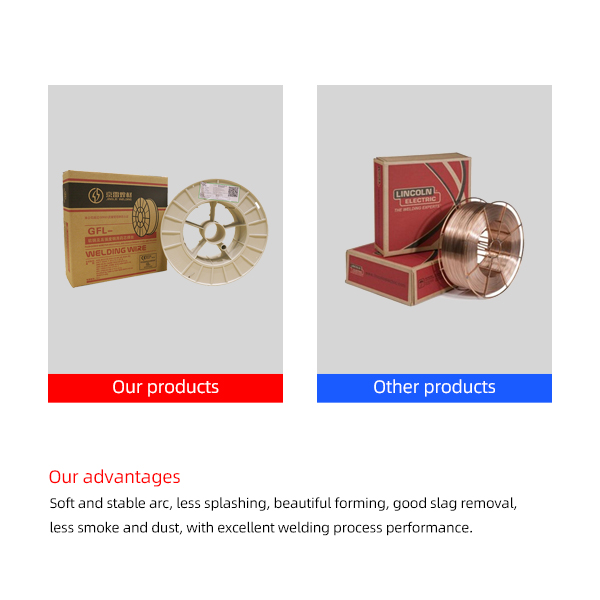

Hais txog peb

Factory fioor zaub

Cov ntaub ntawv thov

Peb lub rooj vag 2 # tsis yog txav

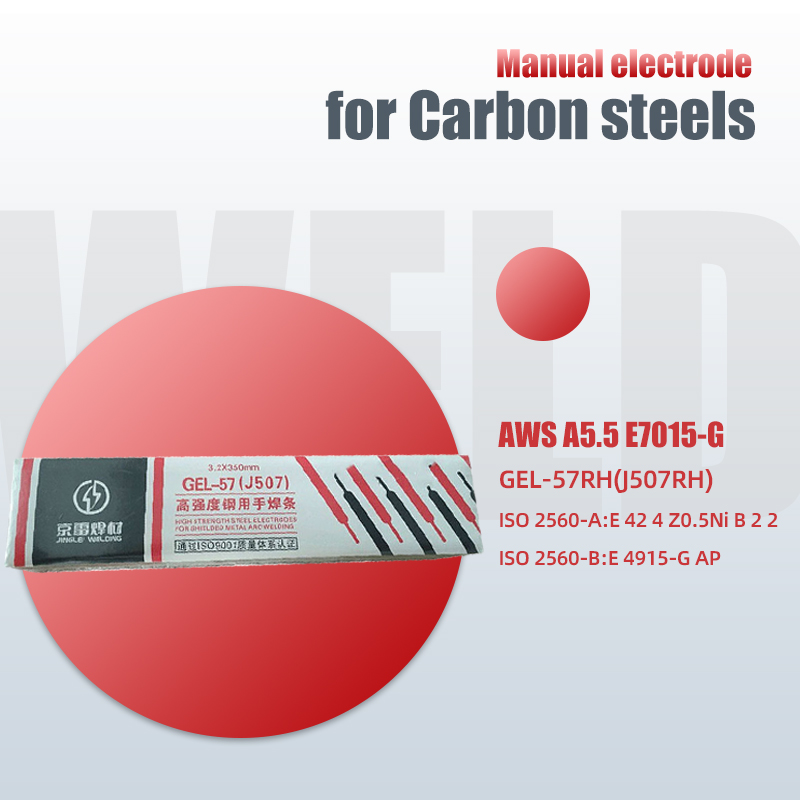

Vuam cov ntaub ntawv rau tsheb ciav hlau

Lub Hoobkas tua

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | AI |

| GB/T RULES | 0.30 Nws | 2.00 Nws | 0.90 ib | 0.20 ib | 0.50 ib | 0.30 Nws | 0.030 Nws | 0.030 Nws | 2.00 Nws |

| AWS RULES | 0.30 Nws | 1.75 ib | 0.30 Nws | 0.20 ib | 0.50 ib | 0.30 Nws | 0.030 Nws | 0.030 Nws | 1.80 ib |

| EXAMPLE VALUE | 0.220 Nws | 0.550 Nws | 0.30 Nws | 0.03 ib | 0.02 ib | 0.01 ib | 0.013 ib | 0.002 ib | 1.5 |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 390 | 490-670 : kuv | AW | - | 18 | ||||

| AWS RULES | 390 | 490-670 : kuv | AW | - | 22 | ||||

| EXAMPLE VALUE | 430 | 590 ua | AW | - | 25 | ||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.4 | 2.8 | 3 | ||||

| VOLT | 24-32 : kuv | 24-35 : kuv | 24-35 : kuv | ||||

| AMP | 260-400 Nws | 280-450 : kuv | 280-450 : kuv | ||||

| LENGTH: MM | 65-70 : kuv | 65-70 : kuv | 90-95 : kuv |

Sau koj cov lus ntawm no thiab xa tuaj rau peb