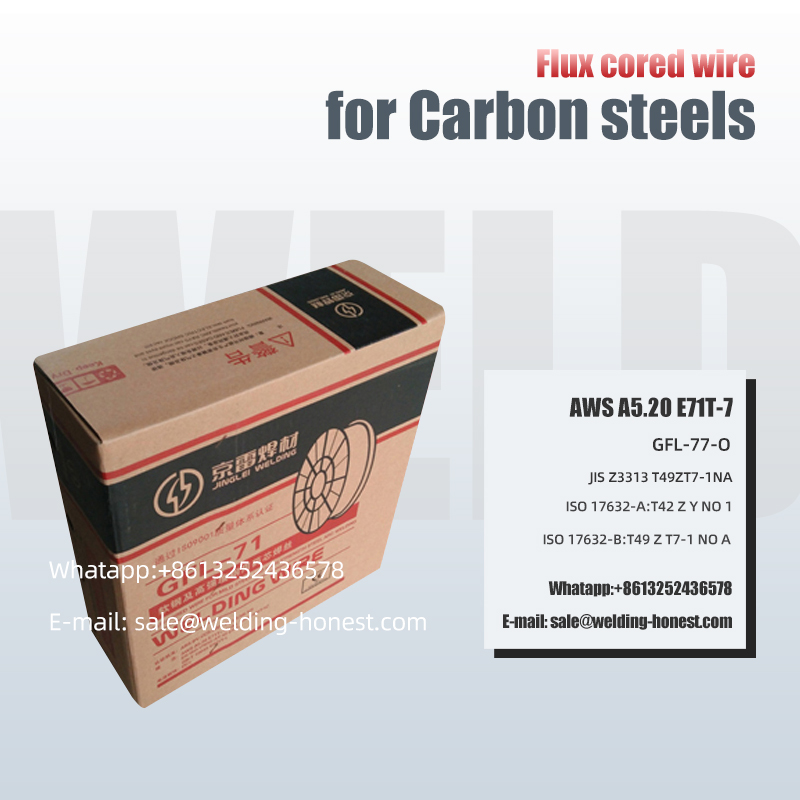

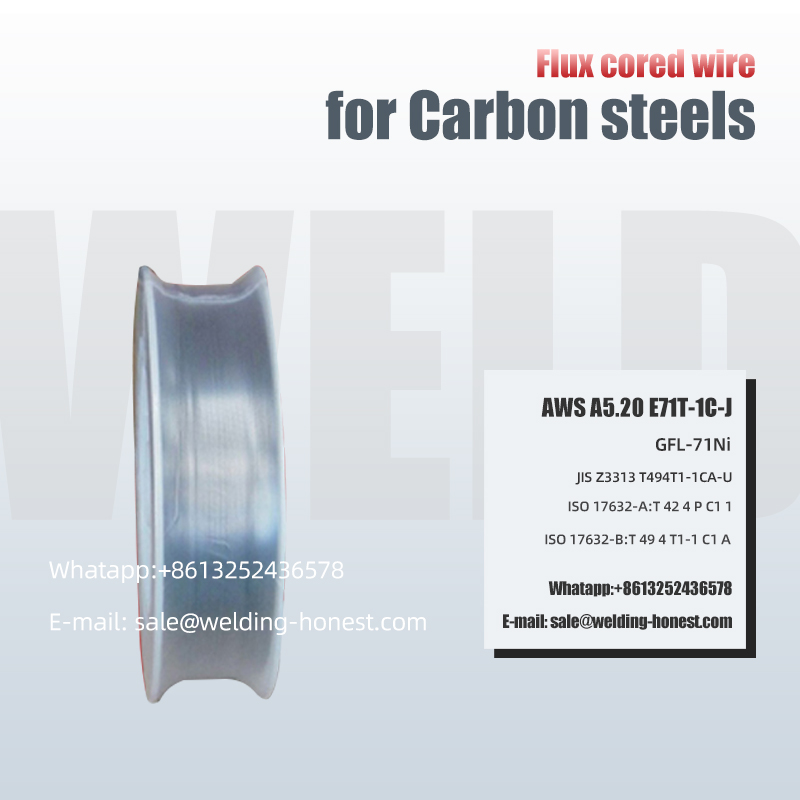

High Carbon steels CO2 Tiv thaiv E70T-1C Flux cored hlau vuam accessories

Daim ntawv thov & Standard

1. Tsim nyog rau kev sib tw tiaj tus thiab fillet vuam ntawm ships, Choj, machinery, tsheb thiab steel qauv.

2. Tus qauv peb tau ntsib:

GB/T10045 T49 2 T15-0 C1 A, AWS A5.20 E70T-1C & A5.20M E490T-1C, ISO17632-A:T 42 2 R C1 3, ISO 17632-B:T49 2 T15-1 C1 AJIS Z3313 T492T15-1CA-U

3.Nws tuaj yeem siv rau vuam ntawm cam khwb cia hlau lossis nruab nrab tuab phaj.

Nta

1. Lub arc yog mos thiab ruaj khov, tsis tshua muaj txaws, zoo nkauj tsim, zoo slag tshem tawm, tsis muaj soot, nrog zoo heev vuam txheej txheem.

2. Zoo heev tiv thaiv priming, zoo tiv thaiv porosity thiab tawg.

Tuam txhab & Hoobkas

Cov khoom muaj pes tsawg leeg thiab cov khoom siv kho tshuab kev taw qhia

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | 0.18 | 2.00 Nws | 0.90 ib | 0.20 ib | 0.50 ib | 0.30 Nws | 0.030 Nws | 0.030 Nws | 0.08 ib |

| AWS RULES | 0.12 | 1.75 ib | 0.90 ib | 0.20 ib | 0.50 ib | 0.30 Nws | 0.030 Nws | 0.030 Nws | 0.08 ib |

| EXAMPLE VALUE | 0.045 ib | 1.45 Nws | 0.50 ib | 0.02 ib | 0.02 ib | 0.01 ib | 0.012 ib | 0.006 ib | 0.01 ib |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 390 | 490-670 : kuv | AW | 27/-20 ib | 18 | ||||

| AWS RULES | 390 | 490-670 : kuv | AW | 27/-20 ib | 22 | ||||

| EXAMPLE VALUE | 500 | 575 ib | AW | 60/-20 | 27 | ||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 1.2 | 1.4 | 1.6 | ||||

| VOLT | 23-34 : kuv | 24-42 : kuv | 25-46 : kuv | ||||

| AMP | 150-320 : kuv | 170-400 Nws | 200-450 | ||||

| MM | 15-20 | 15-20 | 18-25 | ||||

| L/MIN | 15-25 | 15-25 | 15-25 |

CEEB TOOM:

CO2 Tiv thaiv roj, ua ntej cua sov: 150 ± 15 ℃

CERTIFICATION AUTHORITY: ABS/BV/CCS/DNV/GL/LR/NK/CE/JIS

TSEEM CEEB

Daim ntawv pov thawj

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | 0.18 | 2.00 Nws | 0.90 ib | 0.20 ib | 0.50 ib | 0.30 Nws | 0.030 Nws | 0.030 Nws | 0.08 ib |

| AWS RULES | 0.12 | 1.75 ib | 0.90 ib | 0.20 ib | 0.50 ib | 0.30 Nws | 0.030 Nws | 0.030 Nws | 0.08 ib |

| EXAMPLE VALUE | 0.045 ib | 1.45 Nws | 0.50 ib | 0.02 ib | 0.02 ib | 0.01 ib | 0.012 ib | 0.006 ib | 0.01 ib |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 390 | 490-670 : kuv | AW | 27/-20 ib | 18 | ||||

| AWS RULES | 390 | 490-670 : kuv | AW | 27/-20 ib | 22 | ||||

| EXAMPLE VALUE | 500 | 575 ib | AW | 60/-20 | 27 | ||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 1.2 | 1.4 | 1.6 | ||||

| VOLT | 23-34 : kuv | 24-42 : kuv | 25-46 : kuv | ||||

| AMP | 150-320 : kuv | 170-400 Nws | 200-450 | ||||

| MM | 15-20 | 15-20 | 18-25 | ||||

| L/MIN | 15-25 | 15-25 | 15-25 |

CEEB TOOM:

CO2 Tiv thaiv roj, ua ntej cua sov: 150 ± 15 ℃

CERTIFICATION AUTHORITY: ABS/BV/CCS/DNV/GL/LR/NK/CE/JIS