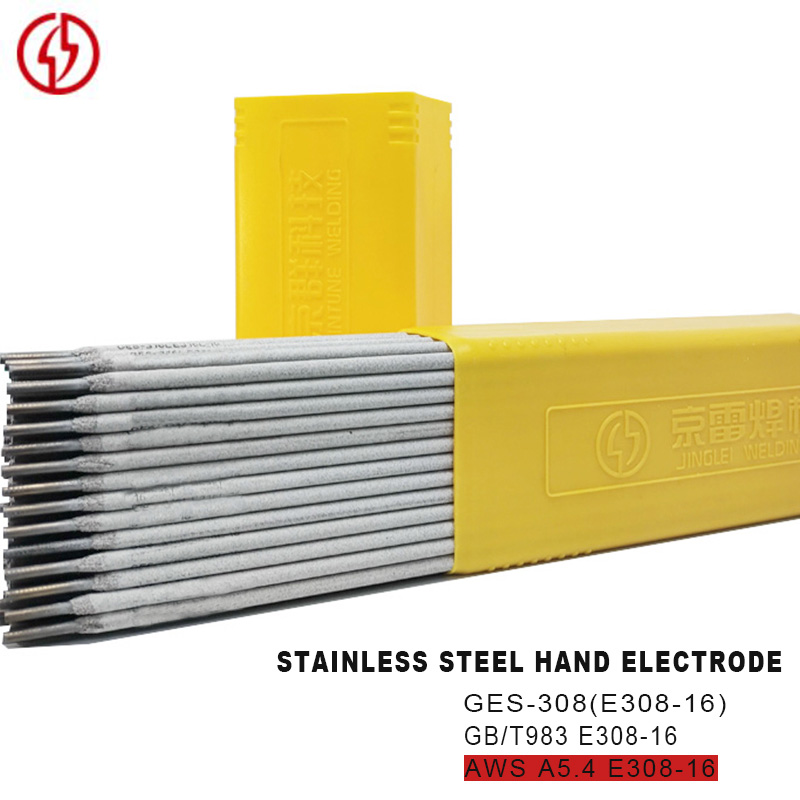

AWS E308-16 Stainless hlau Electrode Vuam khoom

Daim ntawv thov & Standard & Ceeb toom:

1. Haum rau petrochemical, siab nkoj, khoom noj khoom haus, khoom siv kho mob, chiv thiab lwm yam lag luam, vuam 18% CR-8% Ni stainless hlau (SUS304, thiab lwm yam)

2. Tus qauv peb ntsib: GB/T983 E308-16, AWS A5.4 E308-16 & A5.4M E308-16, ISO3581-A:E(19 9) R 1 2, ISO3581-B:ES308-16, JIS Z3221 ES308-16

E308-16 yog tsim los rau welding ntawm 18-8 stainless hlau hom nram qab no: 301, 302, 304 thiab 308. Lub weld deposit muaj cov ntsiab lus tshuaj zoo thiab sib npaug rau kev txaus siab vuam ntawm hom 308, thiab yog li tsim nyog rau vuam 18- 8 hom qis alloy cov ntsiab lus.Suab weld hlau thiab corrosion kuj sib npaug los yog ntau dua li cov niam txiv hlau yog paub tseeb.

Nta

1. Titanium calcium stainless hlau electrode, lub ntsiab muaj pes tsawg leeg yog 18% CR-8% Ni-9%

2. ruaj khov arc, zoo nkauj sib sau, zoo ripples, ob peb splashes, yooj yim de-slagging, zoo hluav taws tsis kam ntawm cov tshuaj ntawm daim tawv nqaij, zoo stomatal kuj.

3. Cov khoom siv ruaj khov, X-ray pass tus nqi siab.

Nco ntsoov:

- Lub vuam electrode yuav tsum tau preheated ntawm qhov kub ntawm 300 ℃ rau 1 teev, preheat tus pas nrig thaum twg nws yog siv.

- Kev xaiv DC fais fab mov, hluav taws xob tam sim no yuav tsum tsis txhob siab.

- Cov xeb, roj, dej thiab lwm yam impurities ntawm vuam yuav tsum tau muab tshem tawm ua ntej vuam.

- Txhawm rau txo qhov kub ntawm cov khoom siv hluav taws xob thiab vuam electrode oscillating amplitude yuav tsum tsis txhob loj dhau.

5. Preheat thiab interlayer-kub yuav tsum nyob twj ywm hauv qab 150 ℃

Tuam txhab & Hoobkas

Cov khoom muaj pes tsawg leeg thiab cov khoom siv kho tshuab kev taw qhia

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULES | 0.08 ib | 0.5-2.5 hli | 1.00 Nws | 18.0-21.0 Nws | 9.0-11.0 Nws | 0.75 ib | 0.040 ib | 0.03 ib | 0.75 ib |

| AWS RULES | 0.08 ib | 0.5-2.5 hli | 1.00 Nws | 18.0-21.0 Nws | 9.0-11.0 Nws | 0.75 ib | 0.040 ib | 0.03 ib | 0.75 ib |

| EXAMPLE VALUE | 0.039 ib | 0.98 ib | 0.75 ib | 19.8 ib | 9.4 ib | 0.01 ib | 0.028 ib | 0.004 ib | 0.05 Nws |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||||||

| GB/T RULES | - | 550 | - | - | 30 | |||||||||

| AWS RULES | - | 550 | - | - | 30 | |||||||||

| EXAMPLE VALUE | - | 605 | - | - | 43 | |||||||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.0 * 250 hli | 2.6 * 300 | 3.2 * 350 | 4.0 * 350 | 5.0 * 350 | |||||||

| ELECTRICITY (Amp) | H/W | 50-75 : kuv | 70-95 : kuv | 80-120 : kuv | 110-160 : kuv | 160-190 : kuv | ||||||

| O/W | 20-50 | 45-80 : kuv | 70-110 : kuv | 90-135 : kuv | - | |||||||

PACKING COV NTAUB NTAWV:

| SEPCIFICATION | LENGTH | PCS / 1 KG | NYIAJ / 1KG | |||

| 2.0 hli | 300 hli | 79pc ua | 2 KG | |||

| 2.6mm ib | 300 hli | 48 Pcs | 2 KG | |||

| 3.2mm ib | 350 hli | 27 Pcs | 5 KG | |||

| 4.0mm ib | 350 hli | 16 Pcs | 5 KG | |||

| 5.0mm ib | 350 hli | 12 Pcs | 5 KG | |||

CEEB TOOM:

H / W: kab rov tav txoj hauj lwm vuam

O / W: hla lub taub hau txoj hauj lwm vuam

Cov xwm txheej

Daim ntawv pov thawj

Cov khoom muaj pes tsawg leeg thiab cov khoom siv kho tshuab kev taw qhia

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULES | 0.08 ib | 0.5-2.5 hli | 1.00 Nws | 18.0-21.0 Nws | 9.0-11.0 Nws | 0.75 ib | 0.040 ib | 0.03 ib | 0.75 ib |

| AWS RULES | 0.08 ib | 0.5-2.5 hli | 1.00 Nws | 18.0-21.0 Nws | 9.0-11.0 Nws | 0.75 ib | 0.040 ib | 0.03 ib | 0.75 ib |

| EXAMPLE VALUE | 0.039 ib | 0.98 ib | 0.75 ib | 19.8 ib | 9.4 ib | 0.01 ib | 0.028 ib | 0.004 ib | 0.05 Nws |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||||||

| GB/T RULES | - | 550 | - | - | 30 | |||||||||

| AWS RULES | - | 550 | - | - | 30 | |||||||||

| EXAMPLE VALUE | - | 605 | - | - | 43 | |||||||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.0 * 250 hli | 2.6 * 300 | 3.2 * 350 | 4.0 * 350 | 5.0 * 350 | |||||||

| ELECTRICITY (Amp) | H/W | 50-75 : kuv | 70-95 : kuv | 80-120 : kuv | 110-160 : kuv | 160-190 : kuv | ||||||

| O/W | 20-50 | 45-80 : kuv | 70-110 : kuv | 90-135 : kuv | - | |||||||

PACKING COV NTAUB NTAWV:

| SEPCIFICATION | LENGTH | PCS / 1 KG | NYIAJ / 1KG | |||

| 2.0 hli | 300 hli | 79pc ua | 2 KG | |||

| 2.6mm ib | 300 hli | 48 Pcs | 2 KG | |||

| 3.2mm ib | 350 hli | 27 Pcs | 5 KG | |||

| 4.0mm ib | 350 hli | 16 Pcs | 5 KG | |||

| 5.0mm ib | 350 hli | 12 Pcs | 5 KG | |||

CEEB TOOM:

H / W: kab rov tav txoj hauj lwm vuam

O / W: hla lub taub hau txoj hauj lwm vuam