AWS A5.13 ENiCrFe-1 Nickel alloys Manual electrode Welding accessories

Daim ntawv thov & Standard

Qhov COBALT-BASED SURFACING ELECTRODE no tuaj yeem siv rau hauv lub tsho ntawm lub tes tsho ntawm lub tes tsho, txiav ntug ntawm cov khoom siv hluav taws xob, SAWTOOTH, SCREW PUSH ROD, HIGH kub thiab HIGH siab VALVE twj tso kua mis HIGH. Qhov nto roughness ntawm lub workpiece yuav tsum tsawg tshaj li Ra12.5μm, thiab nto xeb, roj thiab lwm yam av yuav tsum tau nruj me ntsis tshem tawm. Lub matrix yuav tsum tsis txhob muaj cov kab nrib pleb, qhov pores, xuab zeb thiab lwm yam tsis xws luag, thiab cov npoo thiab cov ces kaum yuav tsum sib npaug. Ua ntej surfacing, qhov kub sib txawv yuav tsum raug xaiv raws li cov khoom siv substrate rau preheating. Thaum cov khoom siv matrix yog pearlitic tshav kub-resistant steel los yog martensitic stainless hlau thiab lwm yam ntaub ntawv uas tsis zoo welding kev ua tau zoo, lub austenitic stainless hlau surfacing txheej yuav tsum tau welded rau lub matrix nto, thiab ces cov cobalt-raws li alloy yuav tsum surfacing tom qab du ua rau. txhim kho qhov tawg tsis kam thiab tsis txhob tawg. AC lossis DC arc vuam fais fab tuaj yeem siv rau D802 thiab D812 electrodes. DC arc vuam fais fab mov yog pom zoo.

Nta

GEH-SL12 titanium calcium coated cobalt-base surfacing electrode. Cobalt-cr-tungsten alloy yog siv los ua cov tub ntxhais hlau. Dc rov qab txuas yog pom zoo. Surfacing hlau tuaj yeem tswj tau zoo hnav tsis kam thiab corrosion kuj ntawm 650 ℃. Ua ntej vuam, nws yuav tsum tau ci ntawm 300-350 ℃ rau 1 teev; Lub hardening txheej ntawm lub hauv paus hlau nto yuav tsum tau muab tshem tawm kom tsis txhob tawg thiab brittleness. Raws li qhov loj ntawm lub hauv paus hlau workpiece thiab hom ntawm lub hauv paus hlau, nws yuav tsum tau preheated ntawm 300-600 ℃, thiab me me tam sim no luv luv arc vuam yog tsim nyog.

Tuam txhab & Hoobkas

Cov khoom muaj pes tsawg leeg thiab cov khoom siv kho tshuab kev taw qhia

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | P | Fe | Nb+Ta | S |

| GB/T RULES | 0.08 ib | 3.5 | 0.80 ib | 13.0-17.0 Nws | ≥62 | 0.02 ib | 11.0 Nws | 0.5-4.0 | 0.015 ib |

| AWS RULES | 0.08 ib | 3.5 | 0.75 ib | 13.0-17.0 Nws | ≥ | 0.03 ib | 11.0 Nws | 1.5-4.0 Nws | 0.015 ib |

| EXAMPLE VALUE | 0.048 ib | 2.97 ib | 0.34 ib | 15.6 ib | 69.6 ib | 0.005 ib | 8.94 ib | 2.65 ib | 0.007 ib |

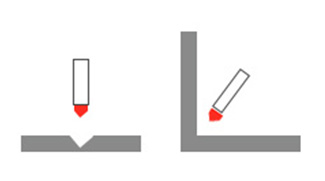

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 300 | 3.2 * 350 | 4.0 * 350 | |||||

| ELECTRICITY (Amp) | Flat / kab rov tav vuam | 69-95 : kuv | 70-115 : kuv | 95-145 : kuv | ||||

| Vertical / overhead welding | 55-80 : kuv | 65-110 : kuv | 80-130 : kuv | |||||

TSEEM CEEB

Daim ntawv pov thawj

Cov khoom muaj pes tsawg leeg thiab cov khoom siv kho tshuab kev taw qhia

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | P | Fe | Nb+Ta | S |

| GB/T RULES | 0.08 ib | 3.5 | 0.80 ib | 13.0-17.0 Nws | ≥62 | 0.02 ib | 11.0 Nws | 0.5-4.0 | 0.015 ib |

| AWS RULES | 0.08 ib | 3.5 | 0.75 ib | 13.0-17.0 Nws | ≥ | 0.03 ib | 11.0 Nws | 1.5-4.0 Nws | 0.015 ib |

| EXAMPLE VALUE | 0.048 ib | 2.97 ib | 0.34 ib | 15.6 ib | 69.6 ib | 0.005 ib | 8.94 ib | 2.65 ib | 0.007 ib |

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 300 | 3.2 * 350 | 4.0 * 350 | |||||

| ELECTRICITY (Amp) | Flat / kab rov tav vuam | 69-95 : kuv | 70-115 : kuv | 95-145 : kuv | ||||

| Vertical / overhead welding | 55-80 : kuv | 65-110 : kuv | 80-130 : kuv | |||||