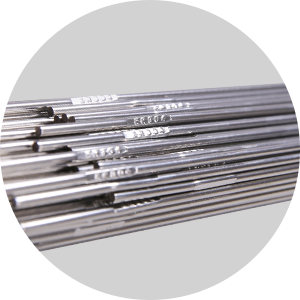

Stainless hlau phau ntawv electrode E410NiMo-16 Soldering jointing

Daim ntawv thov

Haum rau ntau xav tau valve hnav thiab corrosion kuj, hydraulic turbine rotor thiab lwm yam vuam

Daim ntawv pov thawj: JIS

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | |

| GB/T RULES | 0.06 ib | 1.00 Nws | 0.90 ib | 11.0-12.5 Nws | 4.0-5.0 | 0.40-0.70 Nws | 0.04 ib | 0.03 ib | 0.75 ib | |

| AWS RULES | 0.06 ib | 1.00 Nws | 0.90 ib | 11.0-12.5 Nws | 4.0-5.0 | 0.40-0.70 Nws | 0.04 ib | 0.03 ib | 0.75 ib | |

| EXAMPLE VALUE | 0.028 ib | 0.45 ib | 0.6 | 11.6 | 4.8 | 0.55 ib | 0.026 ib | 0.007 ib | 0.13 | |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||||

| GB/T RULES | - | 760 ib | 595-620x1 | - | 10 | ||||||

| AWS RULES | - | 760 ib | 595-620x1 | - | 15 | ||||||

| EXAMPLE VALUE | - | 925 ib | 620x 1 | - | 17 | ||||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.0 * 250 hli | 2.6 * 300 | 3.2 * 350 | 4.0 * 350 | 5.0 * 350 | |||||

| ELECTRICITY (Amp) | H/W | 50-75 : kuv | 70-95 : kuv | 80-120 : kuv | 110-160 : kuv | 160-190 : kuv | ||||

| O/W | 20-50 | 45-80 : kuv | 70-110 : kuv | 90-135 : kuv | ||||||

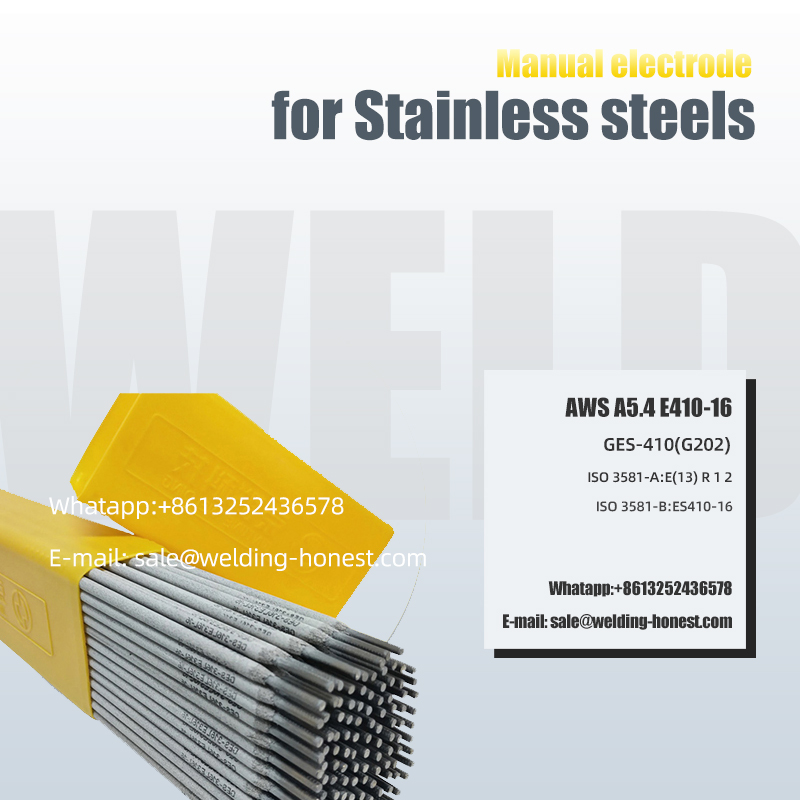

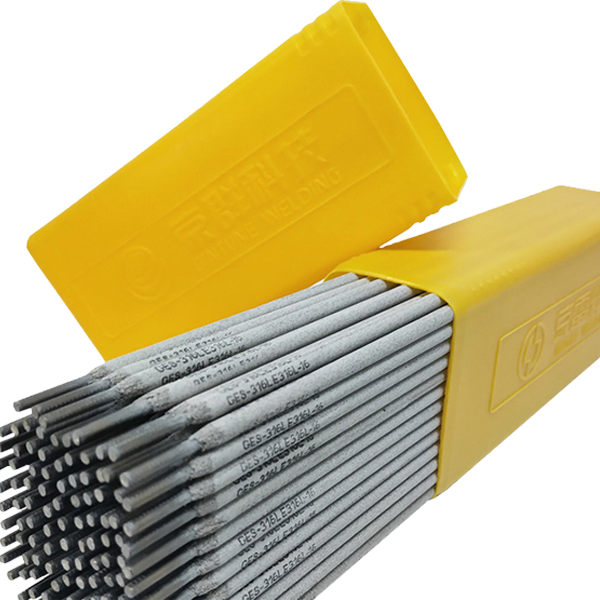

Titanium-calcium martensitic stainless hlau electrode, lub ntsiab muaj pes tsawg leeg yog 11.5% Cr-4.5% Ni-0.55% Mo;

Vim tias qhov sib ntxiv ntawm cov khoom siv hlau NiMo, qhov kev tiv thaiv corrosion yog qhov ruaj khov, qhov hardness thiab kub hnav tsis kam yog txhim kho, thiab cov kab mob khaub thuas tiv thaiv tau zoo. Weld hardness yog hais txog 270HB.

Ruaj khov arc, zoo nkauj tsim, muag heev ripple, me ntsis txaws, yooj yim slag tshem tawm, hluav taws kub tsis kam, zoo porosity kuj.

Ningbo Honest Metal Materials Co, Ltd.is lub tuam txhab kev lag luam thoob ntiaj teb kev lag luam hauv kev tshawb fawb thiab kev tsim kho, tsim khoom, muag thiab kev tswj hwm. Nws tau tsim nyob rau hauv 2020.

9,000 tons ntawm cov tshuaj

Zhejiang Petrochemical 40 lab tons / xyoo refinery integration project

Zhangjiagang Hanzhong Cryogenic Technology Co., Ltd. Tsis tshua muaj kub cia thiab lub thawv thauj khoom

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | |

| GB/T RULES | 0.06 ib | 1.00 Nws | 0.90 ib | 11.0-12.5 Nws | 4.0-5.0 | 0.40-0.70 Nws | 0.04 ib | 0.03 ib | 0.75 ib | |

| AWS RULES | 0.06 ib | 1.00 Nws | 0.90 ib | 11.0-12.5 Nws | 4.0-5.0 | 0.40-0.70 Nws | 0.04 ib | 0.03 ib | 0.75 ib | |

| EXAMPLE VALUE | 0.028 ib | 0.45 ib | 0.6 | 11.6 | 4.8 | 0.55 ib | 0.026 ib | 0.007 ib | 0.13 | |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||||

| GB/T RULES | - | 760 ib | 595-620 × 1 | - | 10 | ||||||

| AWS RULES | - | 760 ib | 595-620 × 1 | - | 15 | ||||||

| EXAMPLE VALUE | - | 925 ib | 620 × 1 | - | 17 | ||||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.0 * 250 hli | 2.6 * 300 | 3.2 * 350 | 4.0 * 350 | 5.0 * 350 | |||||

| ELECTRICITY (Amp) | H/W | 50-75 : kuv | 70-95 : kuv | 80-120 : kuv | 110-160 : kuv | 160-190 : kuv | ||||

| O/W | 20-50 | 45-80 : kuv | 70-110 : kuv | 90-135 : kuv | ||||||

Sau koj cov lus ntawm no thiab xa tuaj rau peb