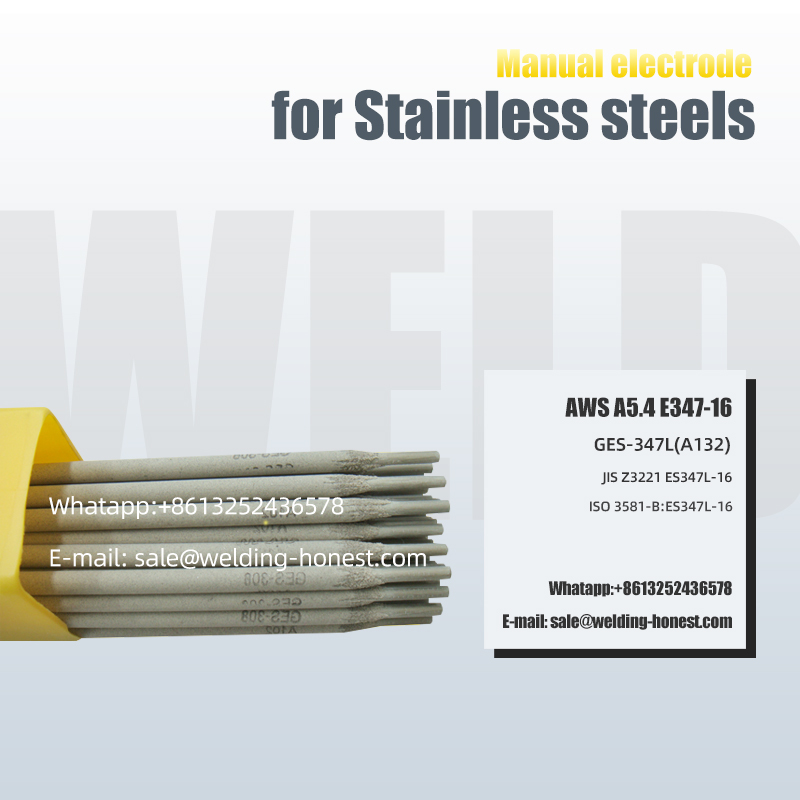

Stainless hlau phau ntawv electrode E312-16 weld fabrication makings

Daim ntawv thov

Nws yog tsim rau txhua yam ntawm cov ntaub ntawv hlau uas nyuaj rau vuam thiab yooj yim rau tawg los yog yooj yim tshwm sim pores, hardening alloy steel thiab lwm yam. Thiab siab carbon steel, cuab yeej steel thiab dissimilar steel hlau vuam.

Tus qauv peb tau ntsib: GB/T983 E312-16, AWS A5.4 E312-16 & A5.4M E312-16, ISO3581-A:E(29 9) R 1 2, ISO3581-B:ES312-16

Daim ntawv pov thawj: CE

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | |

| GB/T RULES | 0.15 | 0.5-2.5 hli | 1.00 Nws | 28.0-32.0 Nws | 8.0-10.5 Nws | 0.75 ib | 0.04 ib | 0.03 ib | 0.75 ib | |

| AWS RULES | 0.15 | 0.5-2.5 hli | 1.00 Nws | 28.0-32.0 Nws | 8.0-10.5 Nws | 0.75 ib | 0.04 ib | 0.03 ib | 0.75 ib | |

| EXAMPLE VALUE | 0.05 Nws | 1.2 | 0.6 | 28.5 Nws | 8.5 | 0.01 ib | 0.02 ib | 0.003 ib | 0.01 ib | |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | - | 660 | - | 15 | ||||

| AWS RULES | - | 660 | - | 22 | ||||

| EXAMPLE VALUE | - | 740 ib | - | 24 | ||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 1.2 | 1.6 | ||||||

| Volt | 22-36 : kuv | 26-38 : kuv | ||||||

| Amp | 120-260 : kuv | 200-300 | ||||||

| Qhuav Extension Length (mm) | 15-20 | 18-25 | ||||||

| Gas ntws (l / min) | 15-25 | 15-25 | ||||||

Titanium calcium stainless hlau nrog tes electrode, weld rau austenite-ferrite biphase qauv, lub ntsiab muaj pes tsawg leeg yog 29% CR-9% Ni, feem ntau hu ua: universal electrode.

Ruaj khov arc, zoo nkauj sib sau, zoo ripples, ob peb splashes, yooj yim de-slagging, zoo hluav taws tsis kam ntawm cov tshuaj ntawm daim tawv nqaij, zoo stomatal kuj.

Cov khoom siv ruaj khov, X-ray pass tus nqi siab.

Ningbo Honest Metal Materials Co, Ltd.is lub tuam txhab kev lag luam thoob ntiaj teb kev lag luam hauv kev tshawb fawb thiab kev tsim kho, tsim khoom, muag thiab kev tswj hwm. Nws tau tsim nyob rau hauv 2020.

400,000 tons super loj ore carrier

Kev siv hluav taws xob thermal

Zhangjiagang Hanzhong Cryogenic Technology Co., Ltd. Cryogenic cia thawv

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULES | 0.15 | 0.5-2.5 hli | 1.00 Nws | 28.0-32.0 Nws | 8.0-10.5 Nws | 0.75 ib | 0.04 ib | 0.03 ib | 0.75 ib |

| AWS RULES | 0.15 | 0.5-2.5 hli | 1.00 Nws | 28.0-32.0 Nws | 8.0-10.5 Nws | 0.75 ib | 0.04 ib | 0.03 ib | 0.75 ib |

| EXAMPLE VALUE | 0.065 ib | 1.45 Nws | 0.75 ib | 29.2 ib | 9.5 ib | 0.02 ib | 0.029 ib | 0.008 ib | 0.10 |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||

| GB/T RULES | - | 660 | - | - | 15 | |||||

| AWS RULES | - | 660 | - | - | 22 | |||||

| EXAMPLE VALUE | - | 805 ib | - | - | 24 | |||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.0 * 250 hli | 2.6 * 300 | 3.2 * 350 | 4.0 * 350 | 5.0 * 350 | |||||

| ELECTRICITY (Amp) | H/W | 50-75 : kuv | 70-95 : kuv | 80-120 : kuv | 110-160 : kuv | 160-190 : kuv | ||||

| O/W | 20-50 | 45-80 : kuv | 70-110 : kuv | 90-135 : kuv | ||||||