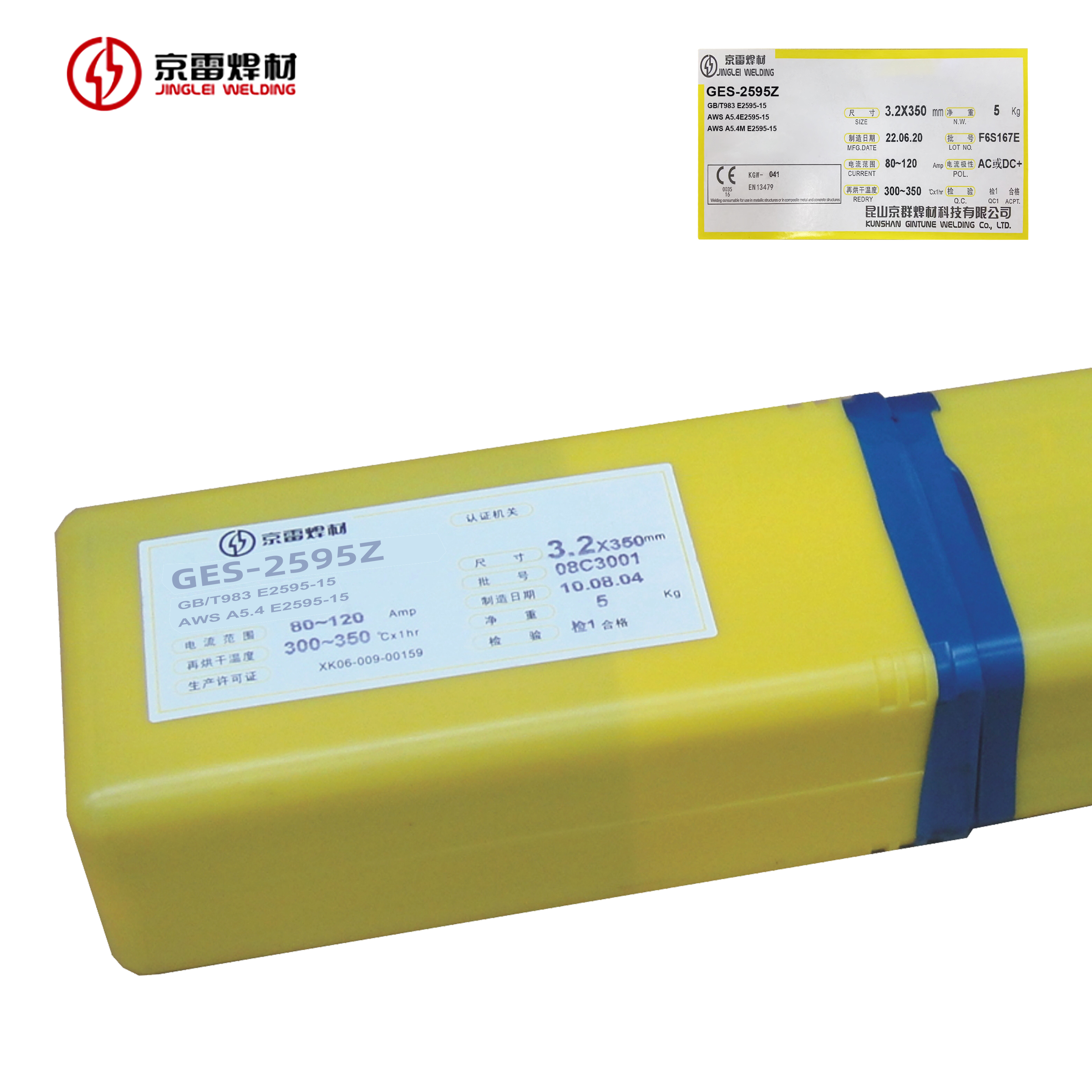

Stainless hlau Electrode E2595-15 HNHS phenol rov qab ntauwd taw tes vuam

WELDING TECHNOLOGY

Tsis txhob cia cov lus nug

Txuas ntxiv mus haunt koj

Arc instability

Unsightly molding

Tshaj tawm ntau dhau

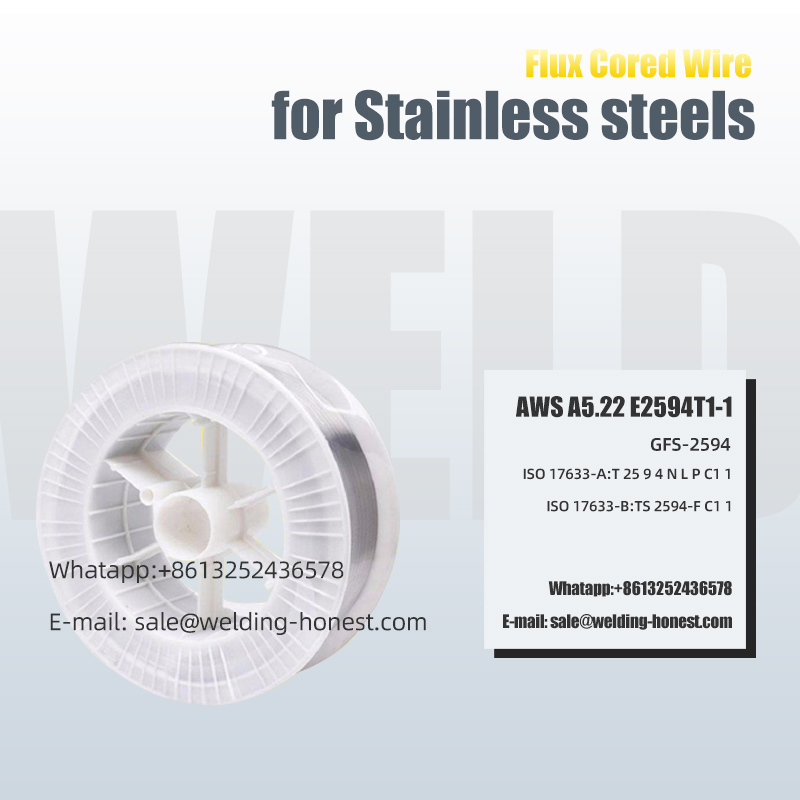

Feem ntau siv nyob rau hauv offshore roj thiab roj, tshuaj,

petroleum thiab petrochemical kev lag luam hauv cov kav dej,

flow khoom kab riser, sau yeeb nkab vuam;

Haum rau vuam ntawm 25% Cr biphase stainless hlau, xws li

UNS 32550 (AIloy255) S32750, S32760 thiab UNS J93370, J93380, J93404 thiab CD4MCuN castings.

Ripple zoo

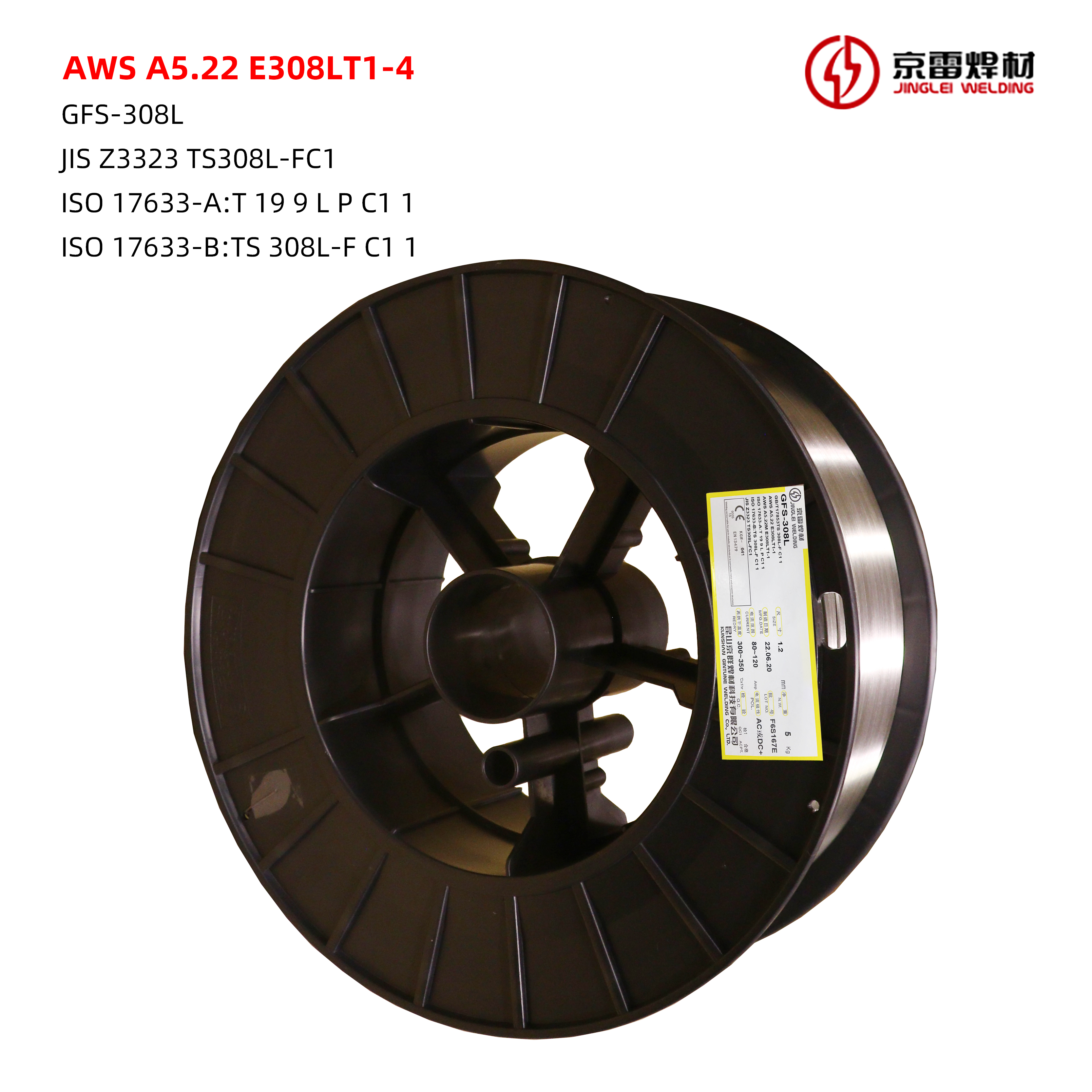

Tsawg hydrogen super duplex stainless hlau tes electrode,

Cov khoom tseem ceeb yog 25.5Cr-9Ni-3.8Mo-0.7Cu-0.7W-0.25N

Cov hlau weld yog austenitic thiab ferritic biphase qauv, thiab corrosion kuj Performance index yog PRE> 40.

Nws muaj lub zog siab thiab ua haujlwm zoo rau pitting thiab kev nyuaj siab corrosion cracking.

Cov tshuab vuam zoo heev, ruaj khov arc, me ntsis txaws, yooj yim tshem tawm slag, zoo nkauj sib sau, muag heev ripples.

Yooj yim slagging

Khoom Parameter

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | Lwm yam |

| GB/T RULES | 0.03 ib | 1.01 Nws | 0.47 ib | 0.02 ib | 0.008 ib | 8.7 ib | 24.9 ib | 3.1 | 0.10 | N: 0.25 |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | IMAPACT VALUE J/℃ | Kev kho cua sov ° C * h | ||||

| GB/T RULES | 9 20 | 22 | - | - | ||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.0 * 250 hli | 2.6 * 300 | 3.2 * 350 | 4.0 * 350 | 5.0 * 350 | |||||

| ELECTRICITY (Amp) | H/W | 30-55 : kuv | 50-85 : kuv | 80-120 : kuv | 100-150 | 140-180 : kuv | ||||

| O/W | 20-50 | 45-80 : kuv | 70-110 : kuv | 90-135 : kuv | - | |||||

Kev them nyiaj yug Hoobkas

Cov khoom tsim nyog rau a

ntau yam kev siv

WELDING TECHNOLOGY

-

85000 m3 Loj heev

Ethane Vinyl Carrier (VLEC)

-

Guangxi Huayi

methanol dehydrating ntauwd

-

Shaanxi Pucheng -50 ℃

propane spherical tank project

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | Lwm yam |

| GB/T RULES | 0.03 ib | 1.01 Nws | 0.47 ib | 0.02 ib | 0.008 ib | 8.7 ib | 24.9 ib | 3.1 | 0.10 | N: 0.25 |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | IMAPACT VALUE J/℃ | Kev kho cua sov ° C * h | ||||

| GB/T RULES | 9 20 | 22 | - | - | ||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.0 * 250 hli | 2.6 * 300 | 3.2 * 350 | 4.0 * 350 | 5.0 * 350 | |||||

| ELECTRICITY (Amp) | H/W | 30-55 : kuv | 50-85 : kuv | 80-120 : kuv | 100-150 | 140-180 : kuv | ||||

| O/W | 20-50 | 45-80 : kuv | 70-110 : kuv | 90-135 : kuv | - | |||||