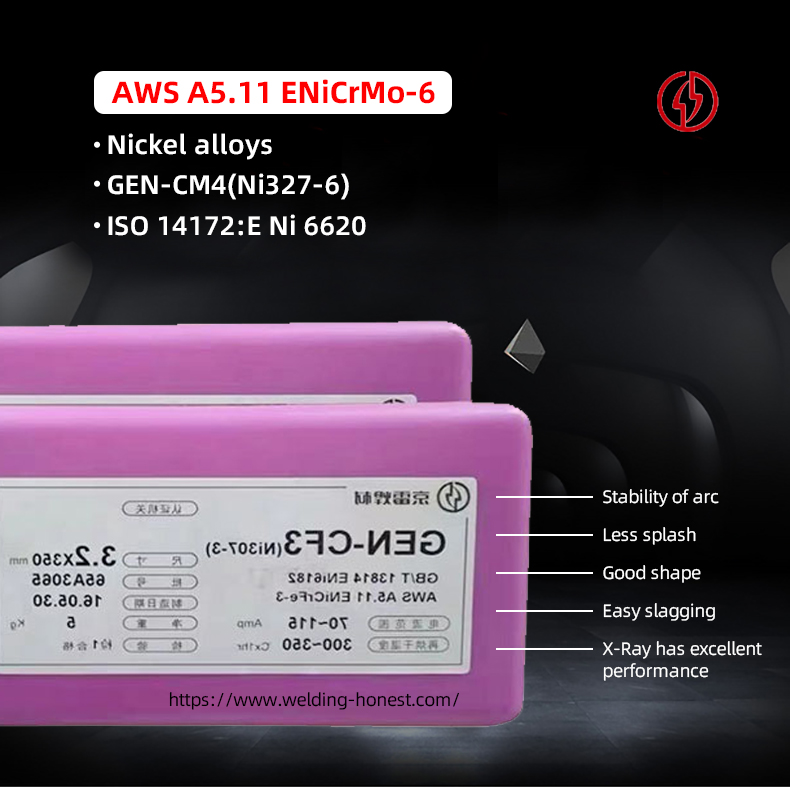

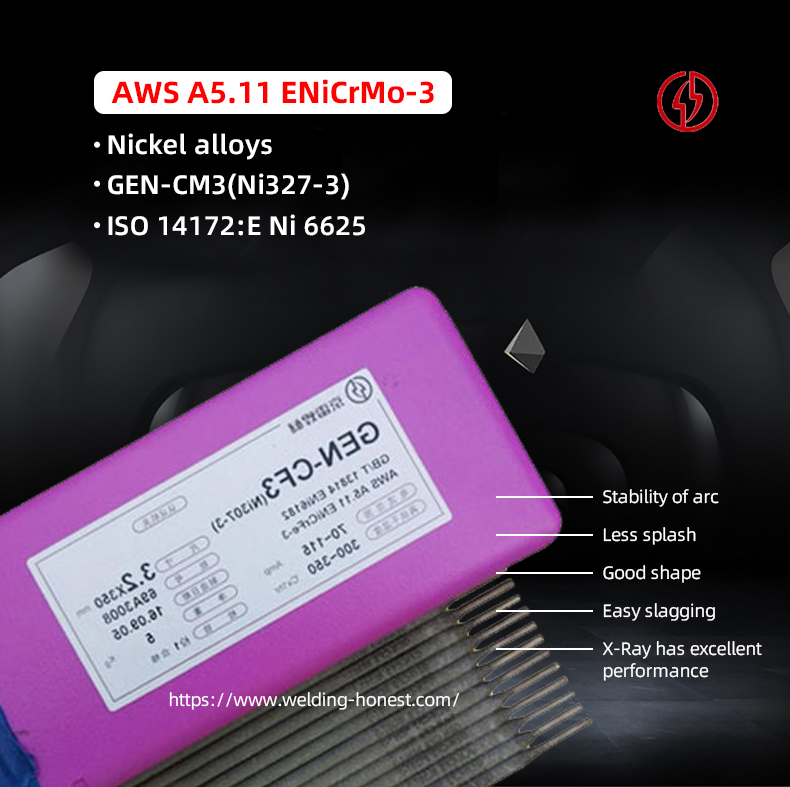

Nickel alloys Phau ntawv electrode ENiCrMo-6 weld fabrication jointing

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Fe | W | Nb+Ta | P | S | |

| GB/T RULES | 0.10 | 2.0-4.0 Nws | 1.00 Nws | 12.0-17.0 Nws | ≥55 | 10.00 Nws | 1.0-2.0 Nws | 0.5-2.0 | 0.02 ib | 0.015 ib | |

| AWS RULES | 0.10 | 2.0-4.0 Nws | 1.00 Nws | 12.0-17.0 Nws | ≥55 | 10.00 Nws | 1.0-2.0 Nws | 0.5-2.0 | 0.03 ib | 0.02 ib | |

| EXAMPLE VALUE | 0.042 ib | 2.91 ib | 0.44 ib | 13.3 | 70.6 ib | 4.15 | 1.45 Nws | 1.350 Nws | 0.008 ib | 0.003 ib | |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 350 | 620 | - | 32 | ||||

| AWS RULES | - | 620 | - | 20 | ||||

| EXAMPLE VALUE | 450 | 720 | 80/-196 | 40 | ||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 300 | 3.2 * 350 | 4.0 * 350 | ||||||

| ELECTRICITY (Amp) | H/W | 65-115 : kuv | 80-140 : kuv | 120-180 Nws | |||||

| O/W | 60-105 : kuv | 70-130 : kuv | 110-170 : kuv | ||||||

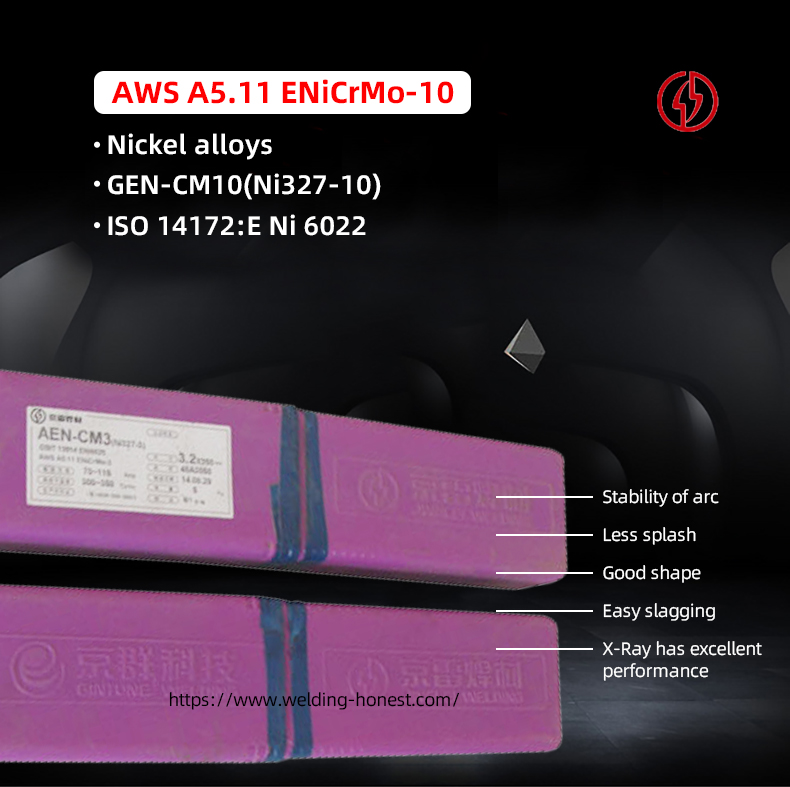

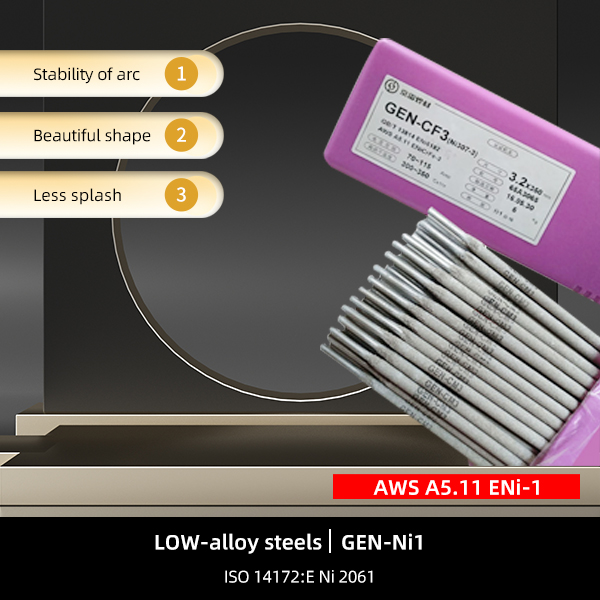

Tsawg hydrogen hom tes electrode, nominal muaj pes tsawg leeg (qhov hnyav feem pua) yog 65Ni-14.5Cr-7Fe-7Mo-1.5W-1.5Nb + Ta, nickel-chrome-molybdenum alloy electrode.

ruaj khov arc, zoo nkauj sib sau, me ntsis txaws, yooj yim slag tshem tawm, zoo porosity tsis kam, txhua yam khoom ntawm molten hlau yog ruaj khov.

Tsawg kub cuam tshuam toughness yog zoo heev ntawm -196 ℃, thiab muaj thermal expansion coefficient zoo ib yam li 9% Ni hlau.

-

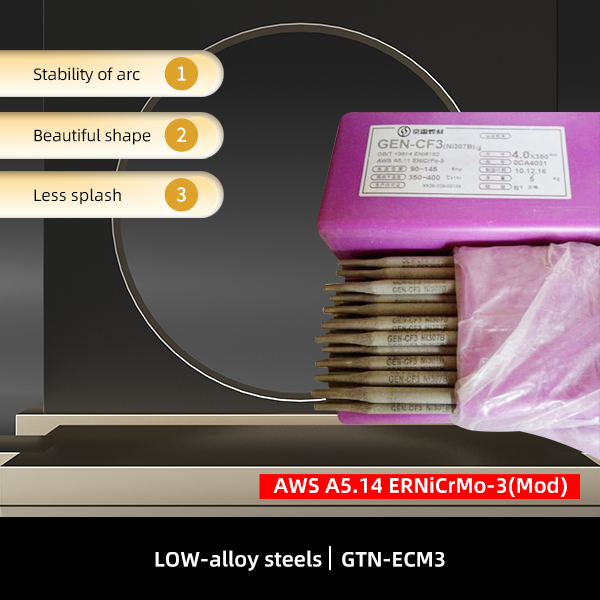

Shandong Zibo Haiyi 8 teeb 3000m³ propylene kheej kheej tank

-

JU2000E jack-up drilling rig

-

85000 m3 Loj heev ethane Ethylene Carrier (VLEC)

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Fe | W | Nb+Ta | P | S | |

| GB/T RULES | 0.10 | 2.0-4.0 Nws | 1.00 Nws | 12.0-17.0 Nws | ≥55 | 10.00 Nws | 1.0-2.0 Nws | 0.5-2.0 | 0.02 ib | 0.015 ib | |

| AWS RULES | 0.10 | 2.0-4.0 Nws | 1.00 Nws | 12.0-17.0 Nws | ≥55 | 10.00 Nws | 1.0-2.0 Nws | 0.5-2.0 | 0.03 ib | 0.02 ib | |

| EXAMPLE VALUE | 0.042 ib | 2.91 ib | 0.44 ib | 13.3 | 70.6 ib | 4.15 | 1.45 Nws | 1.350 Nws | 0.008 ib | 0.003 ib | |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 350 | 620 | - | 32 | ||||

| AWS RULES | - | 620 | - | 20 | ||||

| EXAMPLE VALUE | 450 | 720 | 80/-196 | 40 | ||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 300 | 3.2 * 350 | 4.0 * 350 | ||||||

| ELECTRICITY (Amp) | H/W | 65-115 : kuv | 80-140 : kuv | 120-180 Nws | |||||

| O/W | 60-105 : kuv | 70-130 : kuv | 110-170 : kuv | ||||||

Sau koj cov lus ntawm no thiab xa tuaj rau peb