Nickel alloys Phau ntawv electrode ENiCrFe-4 Vuam cov ntaub ntawv

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Fe | Nb+Ta | P | S | Mo | ||

| GB/T RULES | 0.20 ib | 1.0-5.0 Nws | 1.00 Nws | 13.0-17.0 Nws | ≥60 | 12.00 Nws | 1.0-3.5 | 0.02 ib | 0.015 ib | 1-3.5 | ||

| AWS RULES | 0.20 ib | 1.0-3.5 | 1.00 Nws | 13.0-17.0 Nws | ≥60 | 12.00 Nws | 1.0-3.5 | 0.03 ib | 0.02 ib | 1-3.5 | ||

| EXAMPLE VALUE | 0.09 ib | 2.8 | 0.37 ib | 15.35 Nws | 70.75 ib | 6.05 Nws | 1.82 ib | 0.070 ib | 0.005 ib | 2.43 ib | ||

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 360 | 650 | - | 18 | ||||

| AWS RULES | - | 650 | - | 20 | ||||

| EXAMPLE VALUE | 464 ib | 727 ib | - | 38 | ||||

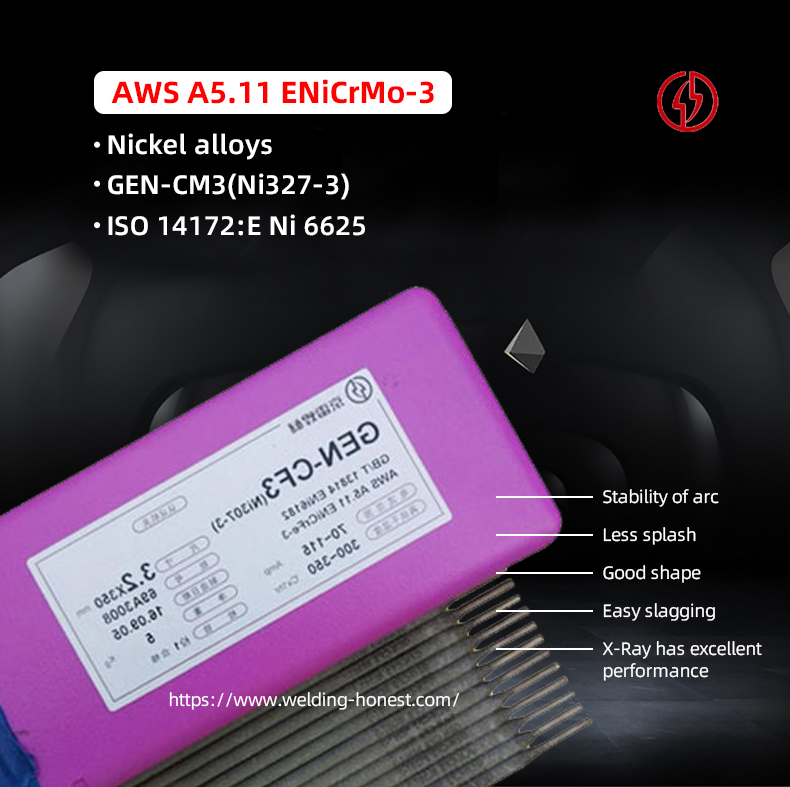

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 300 | 3.2 * 350 | 4.0 * 350 | ||||||||

| ELECTRICITY (Amp) | H/W | 69-95 : kuv | 70-115 : kuv | 95-145 : kuv | |||||||

| O/W | 55-80 : kuv | 65-110 : kuv | 80-130 : kuv | ||||||||

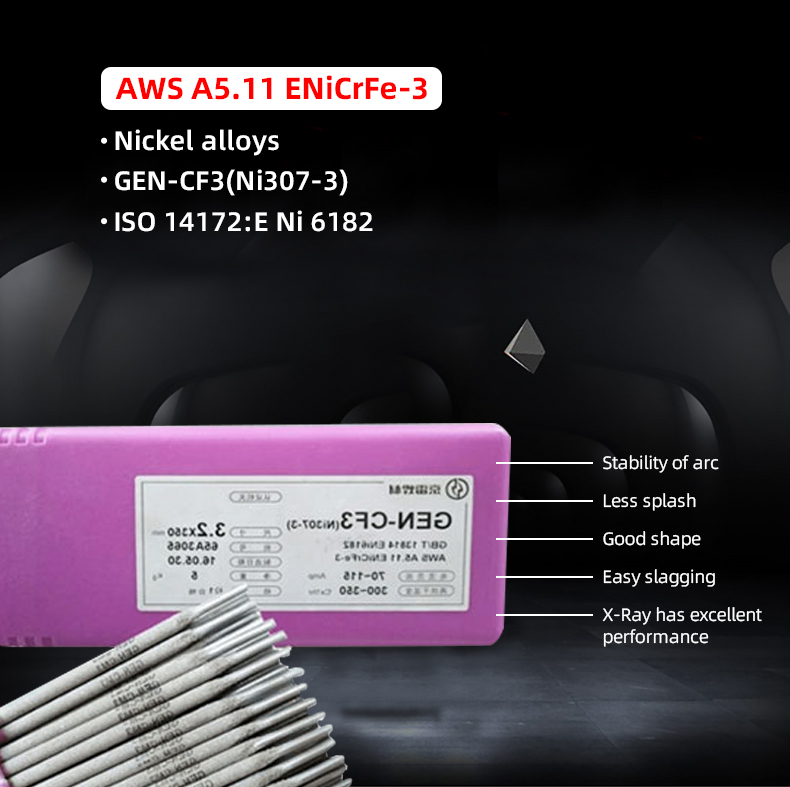

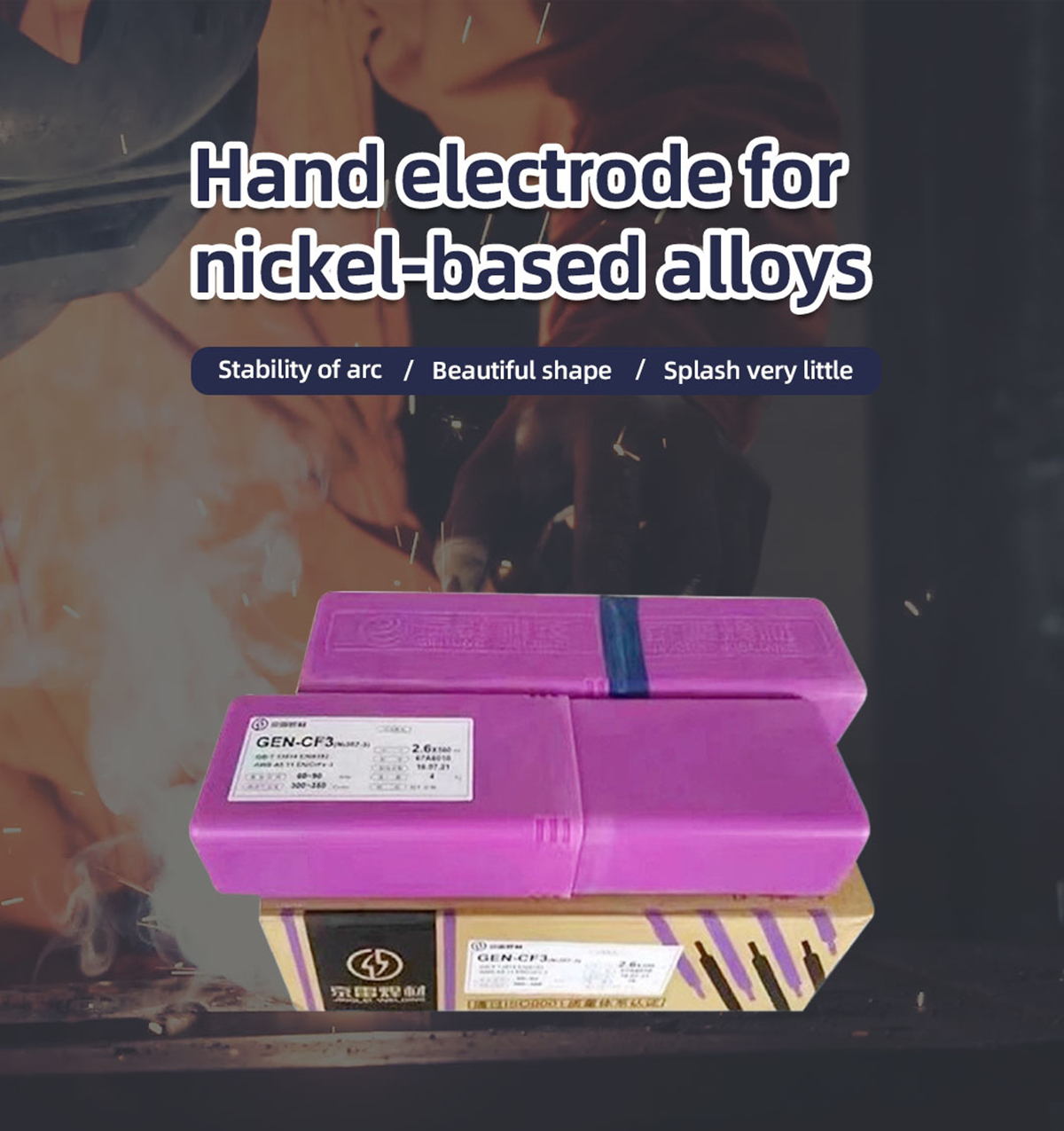

Tsawg H hydrogen hom tes electrode, nominal muaj pes tsawg leeg (qhov hnyav dawb feem) yog 7UNI-15ur-ore-2.OMIl -2. uiWu + Ta-2.5Mo, npib tsib xee - chromium - hlau alloy electrode.

Ruaj khov arc, zoo nkauj sib sau, me ntsis txaws, yooj yim slag tshem tawm, zoo porosity kuj.

Cov khoom siv ntawm cov hlau molten ruaj khov, nws lub zog siab dua ENiCrFe-2 qeb.

-

GDS-2209/GXS-E330 tube surfacing site

-

Vuam cov ntaub ntawv rau LNG tsheb fwj

-

Shanghai Morimatsu Cia Tank

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Fe | Nb+Ta | P | S | Mo | ||

| GB/T RULES | 0.20 ib | 1.0-5.0 Nws | 1.00 Nws | 13.0-17.0 Nws | ≥60 | 12.00 Nws | 1.0-3.5 | 0.02 ib | 0.015 ib | 1-3.5 | ||

| AWS RULES | 0.20 ib | 1.0-3.5 | 1.00 Nws | 13.0-17.0 Nws | ≥60 | 12.00 Nws | 1.0-3.5 | 0.03 ib | 0.02 ib | 1-3.5 | ||

| EXAMPLE VALUE | 0.09 ib | 2.8 | 0.37 ib | 15.35 Nws | 70.75 ib | 6.05 Nws | 1.82 ib | 0.070 ib | 0.005 ib | 2.43 ib | ||

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 360 | 650 | - | 18 | ||||

| AWS RULES | - | 650 | - | 20 | ||||

| EXAMPLE VALUE | 464 ib | 727 ib | - | 38 | ||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 300 | 3.2 * 350 | 4.0 * 350 | ||||||||

| ELECTRICITY (Amp) | H/W | 69-95 : kuv | 70-115 : kuv | 95-145 : kuv | |||||||

| O/W | 55-80 : kuv | 65-110 : kuv | 80-130 : kuv | ||||||||

Sau koj cov lus ntawm no thiab xa tuaj rau peb