Web: www.welding-honest.com Whatsapp: +86 13252436578

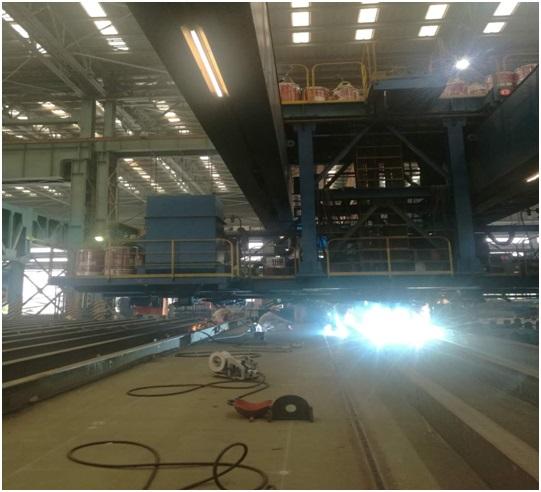

Hauv kev lag luam welding ntawm shipbuilding, txuas hniav, steel qauv thiab lwm yam lag luam, muaj feem ntau ntev txoj cai welds welded, thiab tsis siv neeg vuam feem ntau yog siv, nrog vuam trolleys, tsis siv neeg vuam caj npab thiab ntau npaum li cas electrode vuam txoj kev. Rau T-kab multi-electrode vuam, peb lub tuam txhab launched GFL-70C hlau hmoov hom flux cored hlau nrog GCL-11G hlau hmoov hom vuam hlau, uas tau txais los ntawm ntau thiab ntau tus neeg muas zaub. Qhov kev sib xyaw ua ke ntawm cov vuam no muaj kev kub ceev, zoo heev zinc hmoov-resistant primer, thiab zoo nkauj weld hlaws tsim. Kev ua haujlwm ntawm cov xaim pem hauv ntej GCL-11G yog siab li 97%, feem ntau yog vim cov hlau muab tub lim, thiab cov xaim rov qab GFL-70C ua kom cov khoom siv vuam, thiab vuam ceev tuaj yeem ncav cuag 1000-1400mm. / min. Nws yog qhov tsim nyog rau kev sib tsoo thiab tiaj tus fillet vuam ntawm ntau yam qauv xws li nkoj, txuas hniav, tshuab, tsheb thiab steel qauv.

Multi-electrode T-kab kev kub ceev thiab siv tau zoo vuam

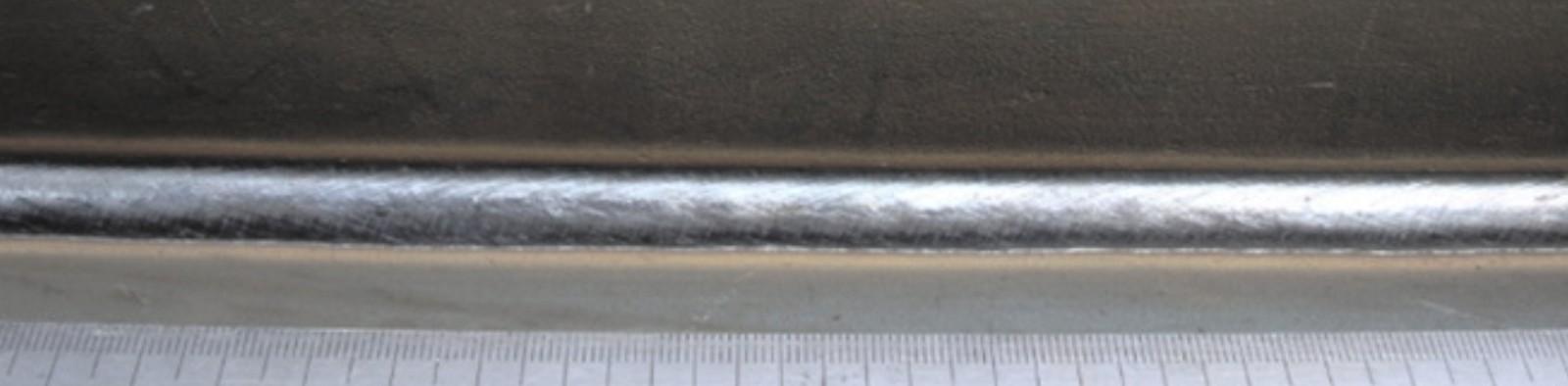

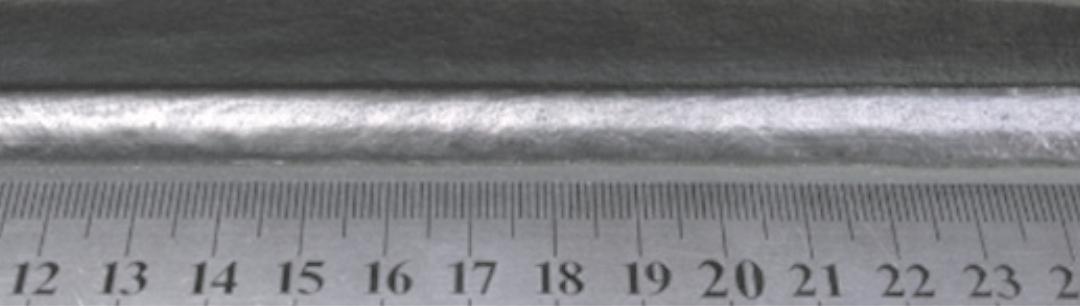

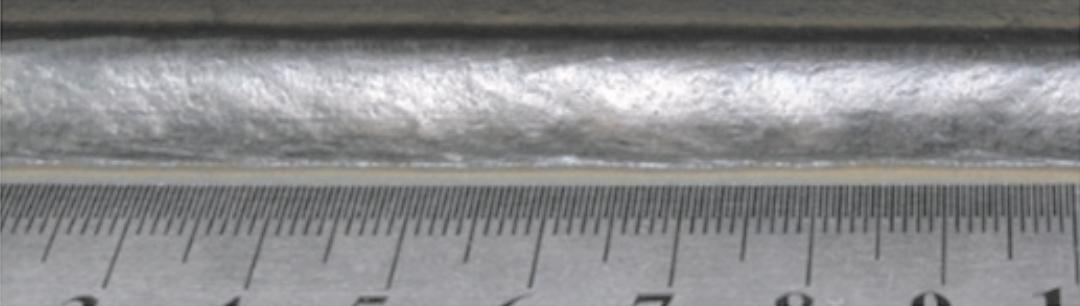

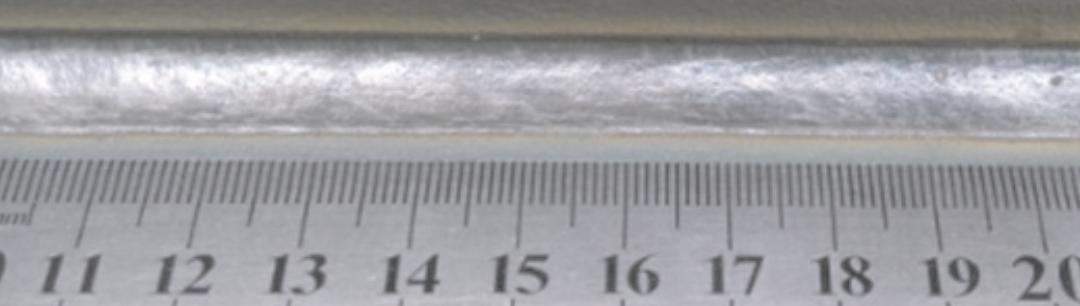

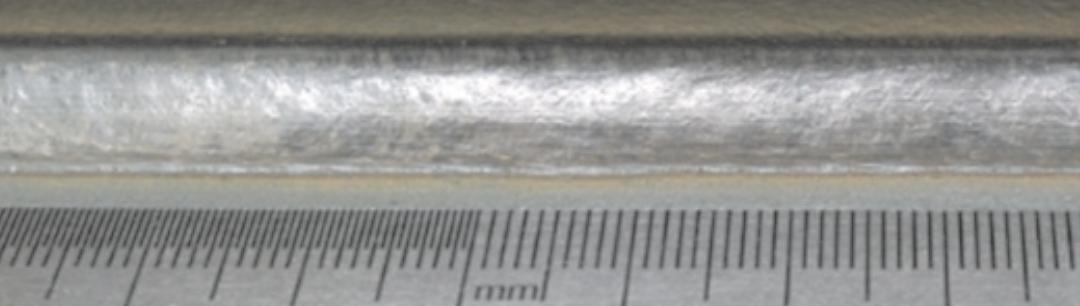

Qhov tshwm sim ntawm weld slag tshem tawm

Ua ntej deslagging

Tom qab deslagging

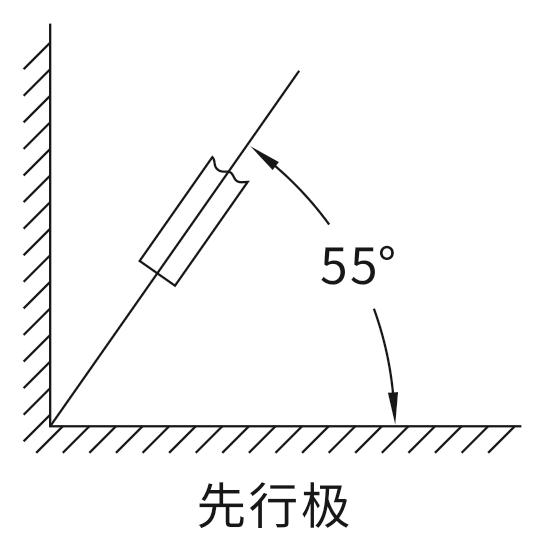

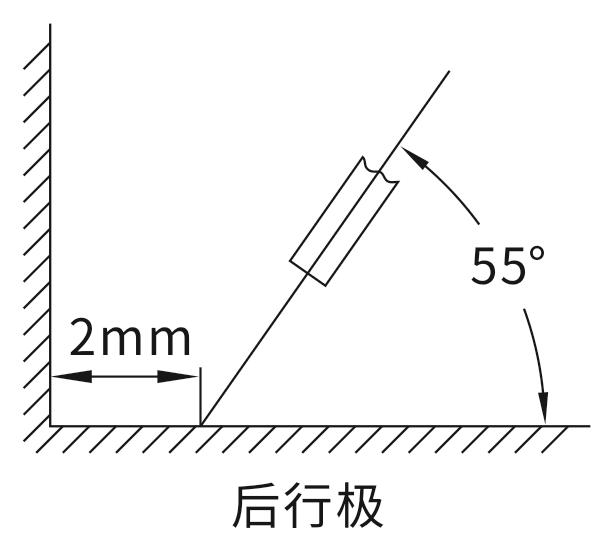

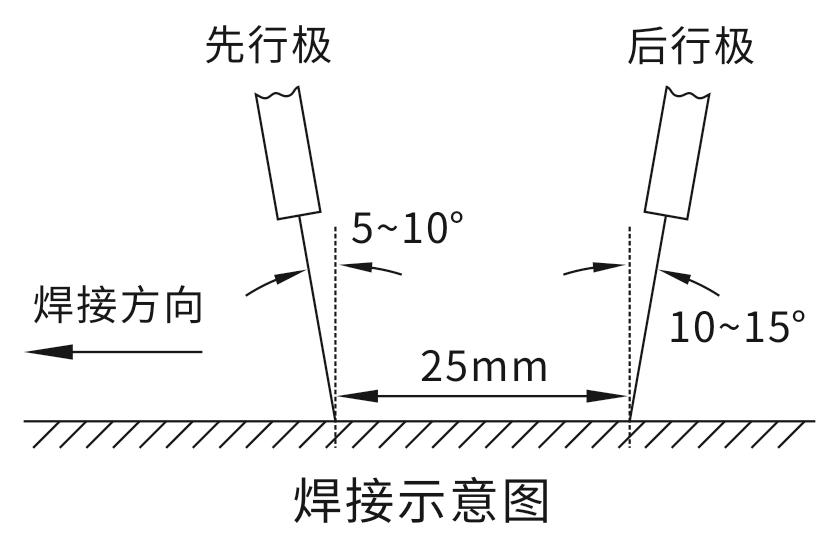

Qhov loj tshaj ntawm txoj kev vuam no yog nws cov kev ua haujlwm siab, ntau lub tshuab electrode vuam tib lub sijhawm, thiab tsis tas yuav txhawj xeeb txog kev cuam tshuam ntawm polarity thiab magnetic teb. Txhua pawg ntawm fillet welds muaj ob txheej vuam torches, thiab txhua pab pawg muaj nyob rau pem hauv ntej thiab nram qab. Cov xaim pem hauv ntej tau zoo dua porosity tsis kam thiab ua haujlwm ntau ntawm cov hlau muab tub lim. Lub nraub qaum tsuas yog yuav tsum tau ua kom ntseeg tau tias cov hlaws vuam yog tsim tiaj tus, zoo ib yam thiab huv. Cov yam ntxwv uas twb muaj lawm ntawm cov hmoov hlau hmoov hom flux cored hlau, raws li cov xaim rov qab ntawm kev sib xyaw ua ke, tsuas yog tuaj yeem ua tau raws li qhov yuav tsum tau ua ntawm nws cov duab sib xws thiab cov tsos. Lub vuam torch lub kaum sab xis thiab qhov kev ncua deb ntawm txoj kev vuam no tau qhia hauv daim duab hauv qab no:

Hybrid heev ceev ceev fillet vuam:

Nco tseg: Kho qhov kev ncua deb ntawm lub hauv ntej thiab nram qab cov xov hlau raws li qhov tseeb ntawm lub pas dej molten thaum vuam

Txoj kev vuam no tuaj yeem tau txais qhov xav tau vuam xav tau los ntawm kev kho cov vuam sib txawv. Los ntawm kev kho cov vuam tam sim no, qhov hluav taws xob, vuam ceev, vuam teeb nrug, thiab lwm yam, qhov sib txawv vuam lub kaum sab xis tuaj yeem tau txais.

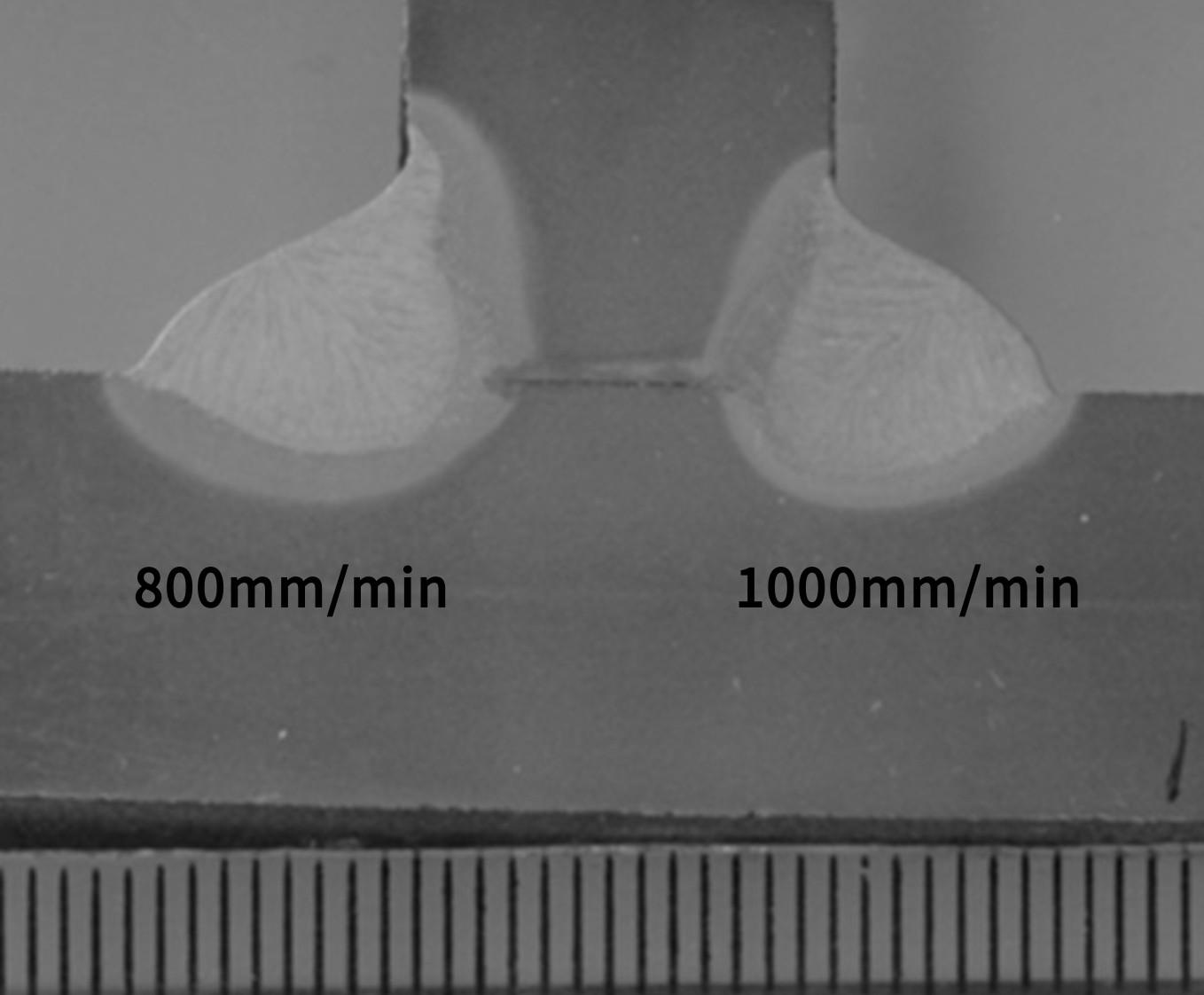

Mixed heev ceev ceev fillet vuam piv txwv 1

GCL-11G (advanced electrode) / GFL-70C (rov qab electrode) 1.4mm:

| Tam sim no thiab voltage | vuam ceev hli/min | Solder ceg ntev |

| Pioneer 360A / 32V Ua raws chav kawm 360A / 38V Electrode nrug 25MM | 800 | 9-10 |

| 1000 | 7–8 |

| ko taw ntev | 9.0 ib | ko taw ntev | 7.0 ib | |

| Convexity | 0.4 | Convexity | 0.8 ua | |

| Nkag mus | 2.0 | Nkag mus | 2.2 |

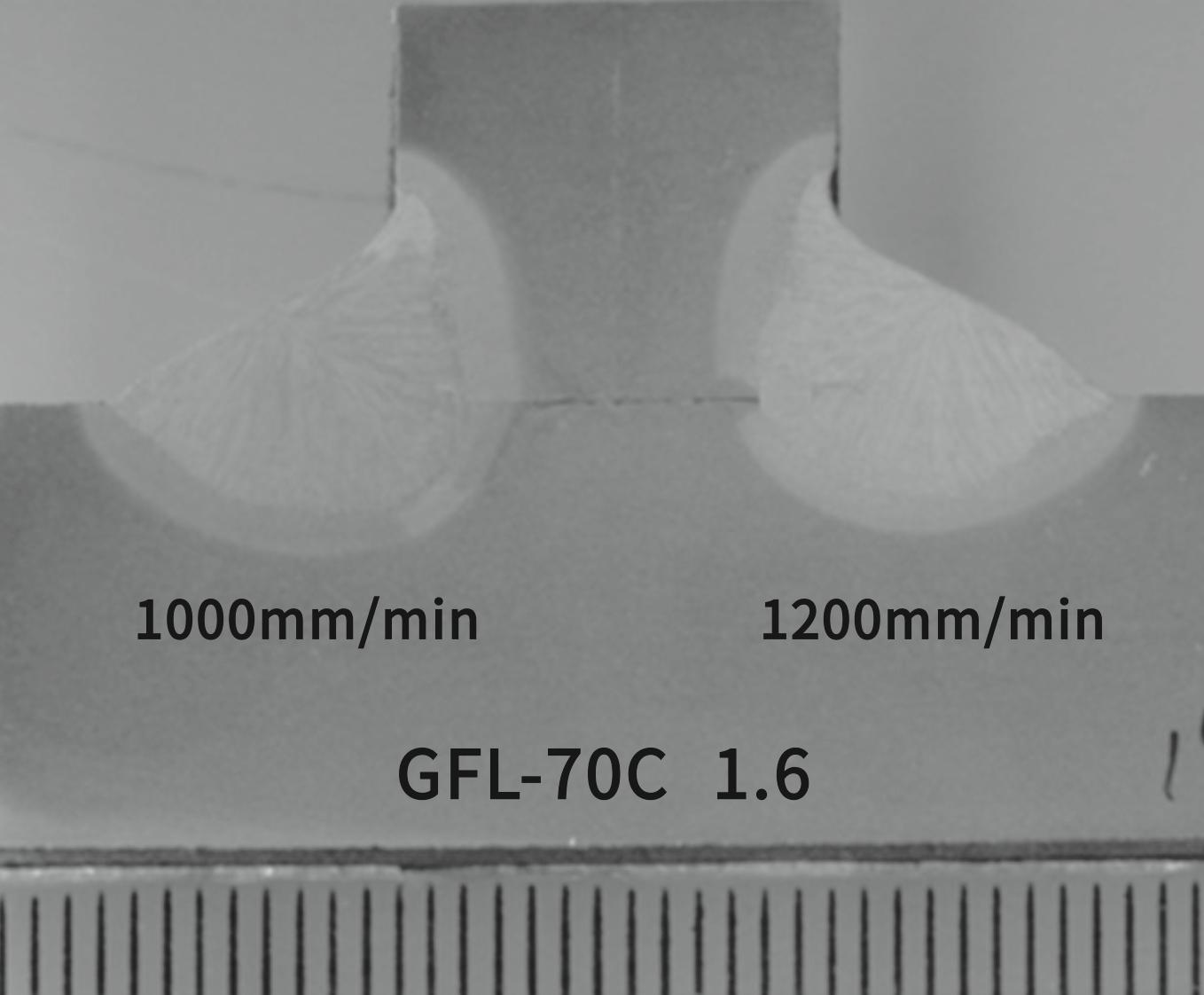

Mixed heev ceev ceev fillet vuam piv txwv 2

GCL-11G (advanced electrode) / GFL-70C (rov qab electrode) 1.6mm:

| Tam sim no thiab voltage | vuam ceev hli/min | Solder ceg ntev |

| Pioneer 360A / 32V Ua raws chav kawm 360A / 38V Electrode nrug 25MM | 1000 | 8-9 |

| 1200 | 7–8 |

Kev txheeb xyuas qhov nkag

| ko taw ntev | 8.0 ib |

| ko taw ntev | 7.0 ib |

| Convexity | 0 | Convexity | 0.3 | |

| Nkag mus | 2.4 | Nkag mus | 2.7 |

GCL-11G + GFL-70C vuam kev pom zoo

| Vuam qeb | Specification mm | vuam specification | vuam ceev hli/min | Solder ceg loj mm | Lus ceeb toom | |

| Pem hauv ntej txhob lo lo ntxhuav | Rov qab txhob lo lo ntxhuav | |||||

| ua ke | 1.4 | 350-400 A 32-36 V | 320-380 A 36-38 V | 700- 1000 | 5-8 | Cov xaim pem hauv ntej yog GCL-11G, feem ntau yog siv rau kev sau, siab tam sim no, tsis tshua muaj hluav taws xob; Cov hlau nram qab yog GFL-70C, siab voltage, tsis tshua muaj tam sim no |

| 1.6 | 360-420 A 36-38 V | 320-400 A 36-38 V | 1000- 14 000 | 5-8 | ||

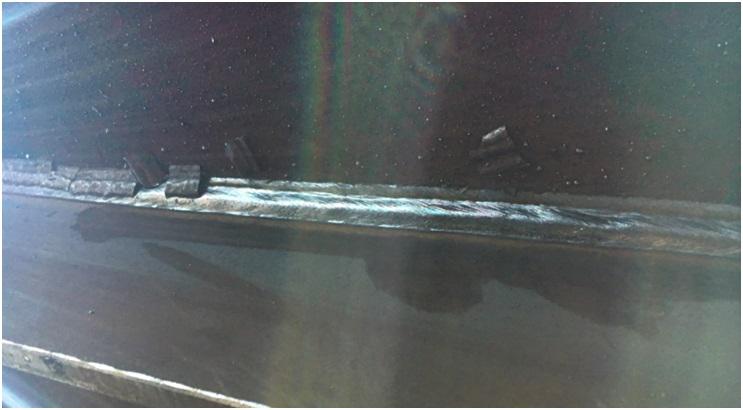

Lwm qhov: 9-12mm vuam lub kaum ntse ntse tuaj yeem ua tiav los ntawm kev kho qhov tshwj xeeb vuam lub kaum sab xis thiab vuam ceev. Weld hlaws raws li qhia hauv qab no:

12mm loj vuam kaum

Rau txoj kev vuam no, thov ua raws li cov lus qhia thiab kev ceev faj hauv qab no

1. Ntxuav cov khib nyiab ntawm qhov chaw, xeb, roj stains, thiab oxidation residues, txwv tsis pub nws yuav ua rau lub qhov hws lossis qhov tsis zoo xws li molding tsis zoo.

2. Cov dej vapor ntau dhau yuav cuam tshuam rau qhov vuam zoo thiab ua rau lub qhov hws. Yog tias cov av noo siab, dehumidification yuav tsum tau ua ua ntej welding, thiab ib sab welding thaum hmo ntuj yuav tsum zam.

3. Lub thickness ntawm cov xim zaj duab xis yog feem ntau tswj ntawm 15-35um. Yog hais tias cov xim zaj duab xis thickness yog tuab heev, nws yuav yooj yim ua rau pores, thiab nws yuav tsum tau polished yog tias tsim nyog.

4. Cov roj ntws tau tswj tau ntawm 20-25l / min, qhov qhuav elongation yog tswj ntawm li 20 ~ 25mm, thiab cua ceev tshaj 2m / s, thiab yuav tsum muaj vaj tse tsim nyog.

5. Thaum ua ke vuam:

(1) Cov xaim pem hauv ntej GCL-11G vuam fais fab vaj huam sib luag xaiv cov khoom siv iav, thiab cov hlau nram qab GFL-70C vuam fais fab vaj huam sib luag xaiv cov tub ntxhais iav;

(2) Thaum welding fillet welds, txhua pawg ntawm quadrupoles yog nqa tawm nyob rau hauv ib txoj kev ntawm kev sib ntsib nrog rau pem hauv ntej thiab nram qab xov hlau.

Cov lus saum toj no tsuas yog siv rau kev siv xwb, thov koj xav paub ntxiv rau kuv yog tias muaj qhov tsis tsim nyog.

More information send E-mail to export@welding-honest.com

Post lub sij hawm: Dec-20-2022