Whatsapp:+8613252436578 E-mail:sale@welding-honest.com

1. kev faib tawm

Raws li tus nqi ntawm cov ntsiab lus carbon, carbon steel tuaj yeem muab faib ua peb pawg hauv qab no:

1) Cov pa roj carbon tsawg C% ≤ 0.25

2) Nruab nrab carbon steel 0.25

3) Cov pa roj carbon siab C%> 0.6

Tsawg Carton

Mid-Carbon

High-Carbon

2. weldability tsom xam

Tus nqi ntawm cov ntsiab lus carbon yog ib qho tseem ceeb siv rau kev txhim kho cov txheej txheem vuam. Raws li cov ntsiab lus carbon nce, lub zog thiab hardness nce, thaum lub plasticity thiab toughness txo, thaum lub zog nce. Hais txog kev hais lus, qhov qis dua cov ntsiab lus carbon, qhov zoo dua qhov weldability, yog li ntawd, cov ntsiab lus carbon yog tus qauv rau kev txiav txim siab qhov nyuaj ntawm cov hlau vuam, thiab cov txheej txheem vuam sib txawv yuav tsum tau txais rau cov ntsiab lus sib txawv.

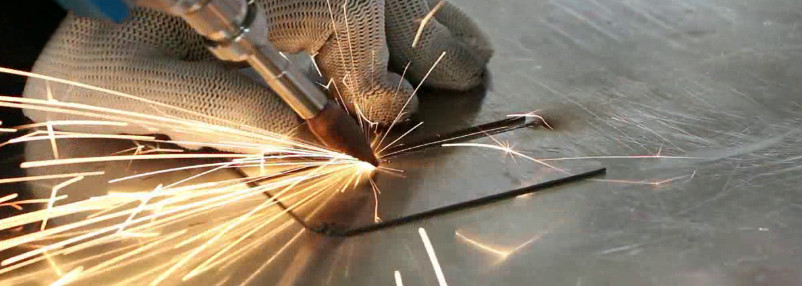

3. Vuam txheej txheem

Kev xaiv cov khoom siv hlau vuam ua raws li lub hauv paus ntsiab lus ntawm "sib npaug zog"

1. Tsawg carbon steel (feem ntau hu ua me me steel)

Cov qib steel xws li Q235 (thaum ntxov hu ua A3 steel), Q255, thiab lwm yam, feem ntau tsis siv tshwj xeeb ntsuas thaum vuam, tsis preheating lossis postheating.

2. Cov pa roj carbon steel nruab nrab

Feem ntau siv cov hlau xws li 30 #, 45 #, thiab lwm yam., 45 # yog cov khoom siv rau kev tsim cov hniav thiab cov ntaub ntawv, nws yog qhov zoo tshaj plaws los siv cov khoom siv qis-hydrogen welding nrog cov khoom tawg zoo, preheating 100-200 ° C; Yog tias nws tsis yooj yim rau preheat, Cr-Ni austenitic stainless hlau vuam khoom tuaj yeem xaiv.

3. High carbon steel

Feem ntau siv cov qib steel xws li 60Si2Mn, T8, T10 thiab lwm yam. 60Si2Mn yog ib lub caij nplooj ntoos hlav hlau, feem ntau tsis ua cov kev kho vuam, feem ntau yog siv los ua rov vuam, yuav tsum yog 250-350 ° C preheating, vuam yuav tsum tau hammered kom tshem tawm kev ntxhov siab, thiab 650 ° C tom qab kev kho cua sov, kuj tuaj yeem ua tau. xaiv Cr-Ni austenitic stainless hlau vuam cov ntaub ntawv

Plaub, me ntsis steel tes electrode dav dav vuam yam tseem ceeb:

Electrode drying kub

| Yam khoom | Hom tawv nqaij | Khoom | Kub | Sijhawm |

| Tsawg carbon steel thiab siab zog steel | Tsawg hydrogen hom | E7016, E7048, E7015, E7015-G | 300-350 ℃ | 60 feeb |

| E7015, E8015-G, E9016-G, E9015-D1, E10015-D2, E12015-G | 330-380 ℃ | |||

| High toughness thiab tsawg hydrogen hom | E7015-G, E7015-G, E8015-G, E9015-G, E10015-G | 350-380 ℃ | 60 feeb | |

| Hlau hmoov tsis tshua muaj hydrogen hom | E7018, E7018-1 | 300-350 ℃ | 60 feeb | |

| E8018-G, E918-G, E9018-M, E10018-D2, E10018M, E11018-G, E11018M, E12018-G | 350-380 ℃ | 60 feeb |

2. Cov dej noo, roj, xeb, thiab lwm yam ntawm cov khoom siv hauv paus yuav tsum raug tshem tawm

3. Siv txoj kev rov qab rau pem hauv ntej los vuam kom tsis txhob stomata ntawm qhov chaw pib

luv arc vuam yuav tsum tau siv, xws li oscillating strips, thiab oscillation amplitude yuav tsum tsis txhob ntau tshaj 3 npaug ntawm cov hlau txoj kab uas hla.

Post lub sij hawm: Oct-13-2022