G115 steel yog ib hom tshiab ntawm cov khoom siv cua sov-resistant steel nrog kev ua tau zoo ntawm qhov kub thiab txias ntawm nws tus kheej tsim nyob rau hauv Suav teb, uas yog tsuas yog siv rau hauv kev tsim cov kav dej loj-ntev tuab-walled kav thiab lwm qhov chaw kub-resistant ntawm 630 ~ 650 ° C. , thiab yog cov khoom siv tseem ceeb los txhim kho qib kev ua haujlwm ntawm cov thee hluav taws xob hluav taws xob thermal.

Txij li xyoo 2016, peb tau txuas ntxiv txhim kho thiab ua kom zoo dua cov khoom siv vuam siv rau G115 steel, thiab tau ua haujlwm ze nrog ntau lub koom haum tshawb fawb thiab cov neeg siv hauv cov txheej txheem no, thiab ua tiav cov txiaj ntsig zoo. Thaum Lub Yim Hli 2020, nws tau ua tiav hauv kev tuav "G115 Heat-resistant Steel Welding Process Technology Seminar" hauv Kunshan, tom qab ntawd cov lus sib tham tau tsim (saib daim duab hauv qab), thiab cov ntaub ntawv qhia tseem ceeb xws li "G115 Steel Vuam. Cov Txheej Txheem Kev Ntsuam Xyuas Kev Ua Tau Zoo Cov Ntsuas Ntsuas" thiab "G115 Steel Vuam Txheej Txheem Txoj Kev thiab Cov Txheej Txheem Tseem Ceeb" tau tsim.

Tom qab qhia meej txog kev ua tau zoo thiab cov ntsiab lus tsis sib xws ntawm lub rooj sib tham, peb txuas ntxiv nqis peev ntxiv hauv kev txhim kho, thiab tau tsim ntau yam khoom siv vuam rau G115 nrog cov txheej txheem vuam zoo heev (electrode thiab TIG vuam hlau tuaj yeem ua tau raws li txoj haujlwm vuam), ruaj khov. kev ua tau zoo, thiab ua tau raws li qhov yuav tsum tau muaj ntawm ntau yam kev ntsuas kev ua tau zoo tau teev tseg los ntawm lub rooj sib tham. Cov qauv tshwj xeeb thiab cov yam ntxwv muaj nyob hauv Table 1 hauv qab no.

Daim ntawv teev cov khoom siv tseem ceeb vuam rau G115 steel

| Yam khoom | KHOOM NPE | NTAUB NTAWV |

| Kev tuav pas nrig | GER-93 | Core hlau hloov hom electrode, lub ntsiab tivthaiv yog 9% Cr-3% W-3% Co-Cu-V-Nb-B, ruaj khov cuam tshuam nyob rau hauv chav tsev kub, thiab muaj ib tug margin. |

| GTAW wire | GTR-W93 | Cov khoom xyaw tseem ceeb yog tib yam li saum toj no, rau priming, ruaj khov thiab ua haujlwm zoo |

| Argon dawb rov qab tiv thaivGTWA rods | GTR-E93 | Coated argon arc vuam hlau, sab nraub qaum tuaj yeem tsis muaj argon txhaws, ob sab molding yog zoo heev |

| SAW kab | GWR-W93 | Lub weld hlaws yog tsim tau zoo, qhov tsis txaus ntseeg qhov tsim nyog tus nqi yog siab, thiab qhov cuam tshuam kev ua tau zoo yog ruaj khov |

| Flux | GXR-93 |

Nyob rau tib lub sijhawm, peb nquag ua cov kev sib pauv, kev ntsuas cov khoom siv hluav taws xob thiab cov txheej txheem sib pauv nrog ntau tus neeg siv, thiab nrhiav lub sijhawm rau G115 kev ntsuas lub raj kom paub meej tias kev ua raws li cov khoom siv vuam siv rau cov txheej txheem tiag tiag.

Thaum Lub Ob Hlis 2022, Guangdong Thermal Power Vuam Lub Tuam Txhab tau soj ntsuam peb G115 steel vuam pas nrig (cov khoom npe: GER-93) rau 115mm tuab yeeb nkab vuam txheej txheem.

Cov hauv qab no yog ib qho kev qhia luv luv ntawm cov txheej txheem kev ntsuas:

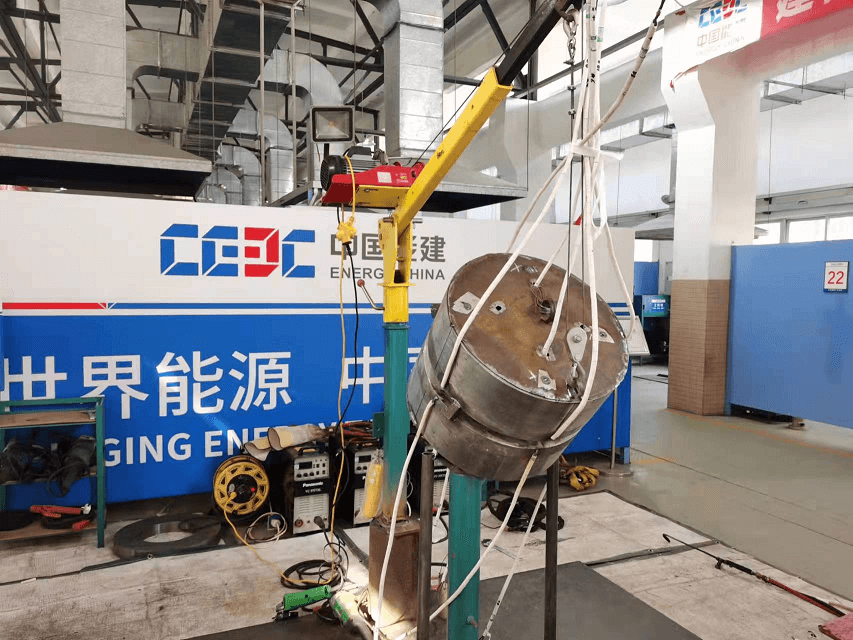

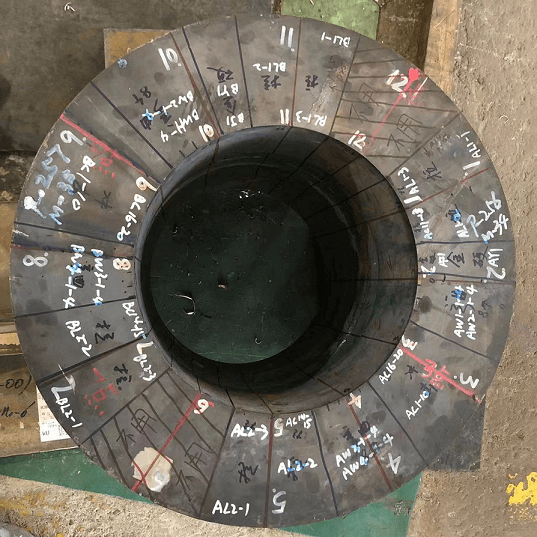

Daim duab 1 yog daim duab ua ntej ntawm cov yeeb nkab fittings rau qhov kev ntsuam xyuas no, thiab cov yeeb nkab haum loj: φ530 × 115mm.

Kev npaj cov yeeb nkab fittings ua ntej vuam

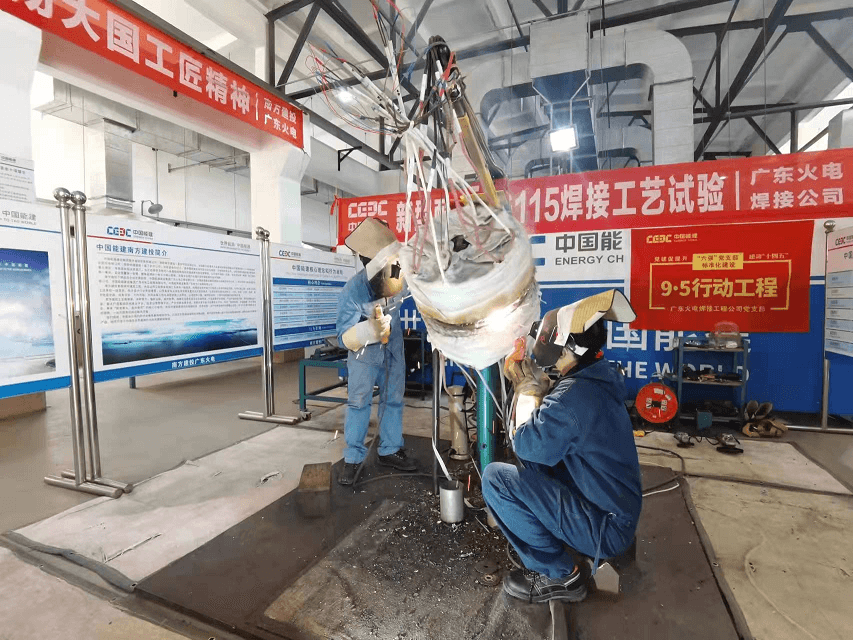

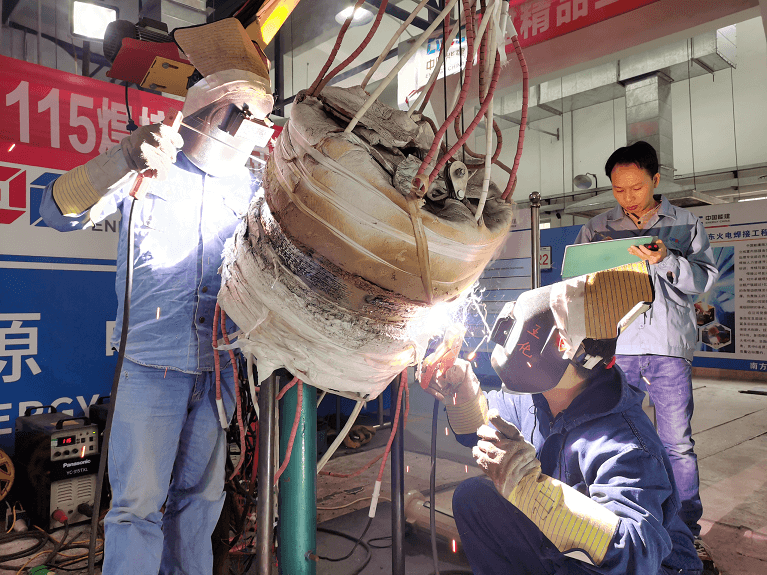

Cov duab 2 thiab 3 yog cov duab piv txwv ntawm cov txheej txheem vuam, txoj haujlwm vuam yog 6G, thiab cov txheej txheem tsis raug kaw nruj me ntsis thiab tswj los ntawm nws cov neeg ua haujlwm txheej txheem.

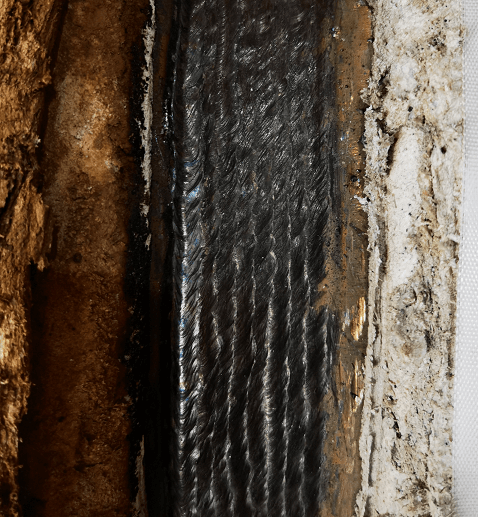

Daim duab 4 thiab daim duab 5 qhia cov vuam tom qab vuam, nws tuaj yeem pom tias cov hlaws vuam yog tiaj tus, lub pas dej molten yog qhov tsim nyog, thiab cov corrugation zoo, uas qhia tau tias cov khoom siv vuam siv tau zoo txhua txoj haujlwm vuam kev ua haujlwm.

Daim duab 6 qhia txog qhov ntev ntawm peb cov electrode tom qab vuam, nws tuaj yeem pom tias qhov seem tom qab vuam yog qhov tsawg dua, uas qhia qhov hluav taws kub tsis zoo ntawm cov electrode, nyob rau hauv lub tshav kub kub ntawm vuam yuav ib txwm tswj lub arc thiab molten pas dej ua ke. , kev siv tus nqi ntawm ib qho electrode yog siab, kom tsis txhob pov tseg.

Cov kev kho cua sov tom qab yog 775 ° C, qhov kub thiab txias rau 12 teev, Daim duab 7 yog daim duab schematic ntawm txhua tus qauv kuaj.

Cov kev ntsuam xyuas ntawm txhua tus qauv ntawm cov yeeb nkab vuam kev soj ntsuam tau raug tso tawm, lub tensile kev ua tau zoo heev, thiab lub tensile daim hlau yog tawg nyob rau hauv txoj hauj lwm ntawm lub hauv paus hlau; Qhov cuam tshuam kev ua haujlwm yog qhov zoo thiab muaj qee qhov npoo; Tus nqi hardness yog nyob rau hauv kab; Cov khoom khoov tau coj los tsis muaj kab nrib pleb thiab lwm yam tsis xws luag. Cov txiaj ntsig tag nrho yog qhov txaus siab thiab ua tau raws li qhov xav tau ntawm kev ntsuas.

Yog tias koj xav paub ntau ntxiv, thov hu rau peb!

Peb yuav txuas ntxiv ua haujlwm ntawm cov txheej txheem hauv cheeb tsam ntawm high-end vuam consumables. Txhawm rau pab txhawb rau lub teb chaws lub tswv yim, kev txuag hluav taws xob thiab kev txo qis emission, Kuv vam tias yuav muaj lub sijhawm los kawm los ntawm cov lag luam zoo li kev xav thiab cov phooj ywg, thiab ua haujlwm ua ke!

Post lub sij hawm: Dec-01-2022