Xyoo 2010, Kaus Lim Qab Teb Kaus Lim Qab Teb POSCO, Daewoo Shipbuilding thiab lub ntiaj teb tsib lub koom haum loj hauv ntiaj teb tau pib txoj haujlwm ntawm "kev sib koom ua ke ntawm cov hlau manganese siab thiab vuam cov ntaub ntawv rau ultra-low kub", thiab ua tiav cov khoom loj ntawm cov hlau manganese siab rau LNG cia tso tsheb hlau luam hauv 2015. Lub Rau Hli 2022, txhawm rau tawg los ntawm cov thev naus laus zis, sab qab teb Kauslim) thiab Pay Camp LN (VLCCs) Ceremony, thiab tau hais tias nws tau tsim cov roj tank tsim tshuab los ntawm steel pretreatment rau vuam thiab sib sau.

1. High manganese steel yog dab tsi?

High manganese steel rau LNG cia tso tsheb hlau luam yog cov hlau alloy nrog manganese cov ntsiab lus ntawm 22-25%, uas muaj qhov kub thiab txias tsis kam thiab siab hnav tsis kam, uas yog qhov pom tseeb dua li cov khoom siv LNG cia tank. cov ntaub ntawv uas South Kauslim tau mob siab rau kev tshawb fawb thiab kev tsim kho rau ntau tshaj kaum xyoo.

2.Kev txheeb xyuas luv luv ntawm cov hom hlau thiab lawv qhov zoo thiab qhov tsis zoo rau LNG cia tso tsheb hlau luam Peb cov khoom siv vuam sib txuam tuaj yeem ua tau raws li cov kev cai nruj no: Txij li cov roj LNG loj loj yog cov khoom siv tseem ceeb ntawm cov khoom siv hluav taws xob zoo ib puag ncig thiab tag nrho LNG kev lag luam saw, cov txheej txheem kev lag luam yog nruj heev thiab tus nqi yog kim. LNG feem ntau yog khaws cia thiab thauj nyob rau hauv qhov kub thiab txias ib puag ncig ntawm -163 ° C. "International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk" yog hu ua "IGC Code". Plaub cov ntaub ntawv kub qis uas tuaj yeem siv rau kev tsim kho LNG suav nrog: aluminium alloy steel, Austria Tensitic stainless hlau, austenitic Fe-Ni alloy steel (tseem hu ua Invar steel) thiab 9% Ni steel (saib Table 1 kom paub meej), thaum 9% Ni hlau yog feem ntau siv thiab dav siv rau LNG roj cia tso tsheb hlau luam. Tab sis qhov tsis zoo yog tias tus nqi tseem siab, cov txheej txheem ua haujlwm yog cumbersome, lub zog yog qhov tsawg, thiab cov ntsiab lus nickel hauv cov khoom yog siab. Nyob rau hauv xyoo tas los no, tus nqi npib tsib xee tau nce ntxiv, thiab cov nqi khoom tau nce ntxiv.

4 cov ntaub ntawv cryogenic uas tuaj yeem siv hauv LNG kev tsim kho raws li "IGC Code"

| Yam tsawg kawg nkaus tsim kub | Main steel hom thiab kev kho cua sov | Impact test kub |

| -165 ℃ | 9% Ni steel NNT lossis QT | -196 ℃ |

| Austenitic stainless hlau - 304, 304L, 316/316L, 321 thiab 347 tshuaj kho | -196 ℃ | |

| Aluminium alloy - 5083 annealed | NO | |

| austenitic hlau-nickel alloy (36% Ni) |

Lub zog sib piv ntawm cov khoom siv LNG feem ntau thiab cov hlau manganese siab tshiab

| Yam khoom | Feem ntau alloy | siab manganese hlau | ||||

| 9% Ni hlau | SIB 304 | Alu 5083-O | Hlau hlau | MC | ||

| Cov ntaub ntawv hauv paus | Tshuaj muaj pes tsawg leeg | Fe-9 Ni | Fe-18.5Cr-9.25Ni | Al-4.5Mg | Fe-36 Ni | M CH mas |

| Microstructure | α1 (+ Y) | γ (FCC) | FCC | FCC | FCC | |

| Yield zogMpa | ≥585 | ≥205 | 124-200 : kuv | 230-350 Nws | ≥400 | |

| Tensile zog Mpa | 690-825 : kuv | ≥515 | 276-352 : kuv | 400-500 | 800-970 : kuv | |

| -196 ℃Kev cuam tshuamJ | ≥41 | ≥41 | NO | NO | ≥41 | |

| Weldments | vuam consumables | Inconal | Type308 | TIAB SA 5356 | - | FCA, SA, GTA |

| Yield zogMpa | - | - | - | - | ≥400 | |

| Tensile zogMpa | ≥690 | ≥550 | - | - | ≥660 | |

| -196 ℃Kev cuam tshuamJ | ≥ 27 | ≥ 27 | - | - | 27 | |

Ultra-low kub high-manganese steel, uas sib xyaw ua ke siab zog, siab tawv, thiab tus nqi qis, muaj kev cia siab rau yav tom ntej LNG roj cia tank thiab ib puag ncig tiv thaiv lwm yam roj cia tank kev lag luam xws li kua ammonia, kua hydrogen, thiab methanol.

Kev sib xyaw thiab kev ua tau zoo ntawm cov hlau manganese siab

Chemical Composition (ASTM Draft)

|

| C | Mn | p | s | Cr | Cu |

| % | 0.35-0.55 Nws | 22.5-25.5 Nws | 0.03 | 0.01 | 3.0-4.0 Nws | 0.3-0.7 hli |

Mechanical cwj pwm

● Cov qauv siv lead ua: lub ntsej muag nruab nrab lub voos voos (γ-Fe)

● Tso cai kub >-196 ℃

● Tawm lub zog > 400MPa (58ksi)

● Tensile zog: 800 ~ 970MPa (116-141ksi)

● Charpy V-notch impact test >41J ntawm -196 ℃ (-320℉)

Taw qhia ntawm peb lub tuam txhab siab manganese steel txuam vuam consumables

Nyob rau hauv xyoo tas los no, peb tau mob siab rau peb tus kheej rau kev tshawb fawb thiab kev loj hlob ntawm high-manganese steel txuam vuam consumables rau LNG cia tso tsheb hlau luam, thiab ntse tsim vuam consumables uas yuav phim cov khoom ntawm high-manganese steel puag cov ntaub ntawv rau LNG cia tso tsheb hlau luam. Cov khoom tshwj xeeb tau qhia hauv Table 2.

Mechanical zog ntawm siab manganese steel txuam vuam consumables deposited hlau

| Lub npe | Txoj hauj lwm | mechanical zog | ||||

| YP | TS | EL | -196 ℃ cuam tshuam | kev kuaj hluav taws xob | ||

| Tsim cov hom phiaj | ≥400 | ≥660 | ≥ 25 | ≥41 | I | |

| GER-HMA Φ3.2 hli | Phau ntawv electrode | 488 ib | 686 ib | 46.0 ib | 73.3 ib | I |

| GCR-HMA-S Φ3.2 hli | Hlau cored hlau | 486 ib | 700 | 44.5 ib | 62.0 ua | I |

Ps.Metal hmoov core submerged arc vuam hlau rau siab manganese steel txais kev sib txuam flux GXR-200 rau siab manganese hlau

Weldability thiab qauv tso saib ntawm siab manganese steel vuam consumables rau LNG cia tso tsheb hlau luam

Weldability ntawm vuam consumables rau siab manganese hlau yog qhia raws li nram no

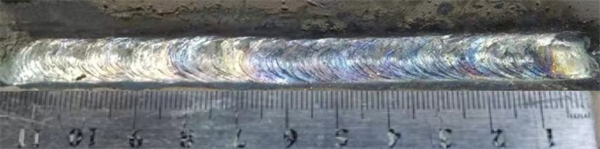

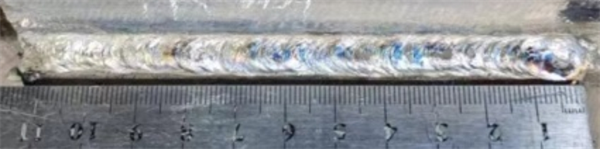

Electrode (GER-HMA) tiaj tus fillet vuam tom qab tshem tawm slag

Electrode (GER-HMA) lub kaum sab xis vuam tom qab tshem tawm slag

Vuam pas nrig (GER-HMA) ua ntej thiab tom qab fillet vuam slag tshem tawm

Hlau hmoov core submerged arc (GCR-HMA-S) weld zaub

Cov qauv ntawm siab manganese steel vuam pas nrig vuam pob qij txha yog qhia raws li hauv qab no

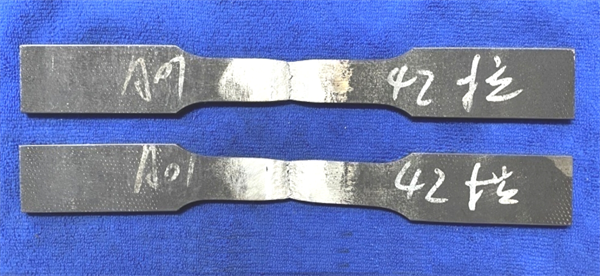

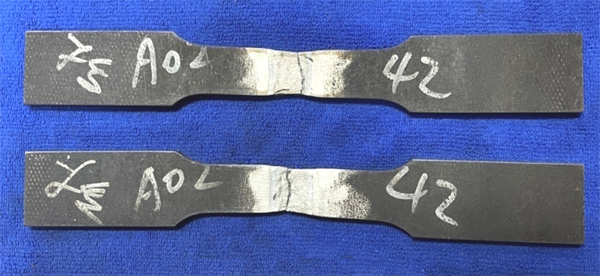

Pav ca vuam (1G) tensile qauv zaub

Vertical welding (3G) tensile qauv zaub

Pav ca vuam (1G) dabtsi yog khoov qauv zaub

Pav ca vuam (1G) dabtsi yog khoov qauv zaub

PS.High manganese steel yog welded nrog vuam rods 1G thiab 3G, tsis muaj kab nrib pleb nyob rau hauv lub ntsej muag dabtsi yog khoov thiab rov qab khoov qauv, thiab cov kab nrib pleb kuj zoo.

Post lub sij hawm: Nov-22-2022