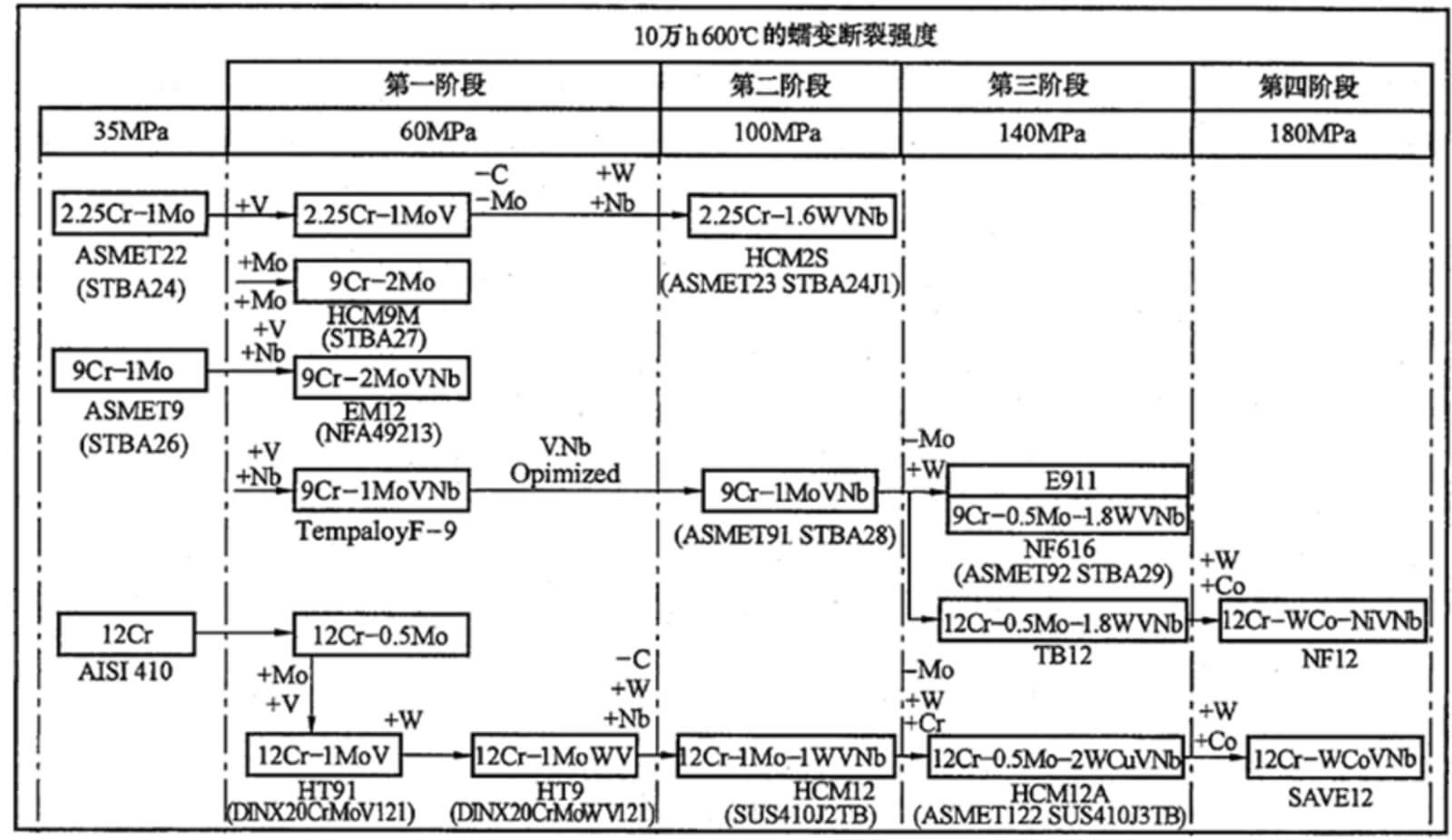

Kev loj hlob ntawm ferritic tshav kub-resistant steel

Nce Cr-1.25Cr rau 12Cr

Ntxiv V, Nb, Mo, W, Co, thiab lwm yam.

Txoj kev loj hlob ntawm ferritic tshav kub-resistant steel

Nco tseg:

Raws li kev xyaum ua thoob ntiaj teb, lub npe hu ua pearlite, bainite, thiab martensitic heat-resistant steels nyob rau hauv boiler thiab pipeline steels yog sib sau ua ke hu ua "ferritic heat-resistant steels".

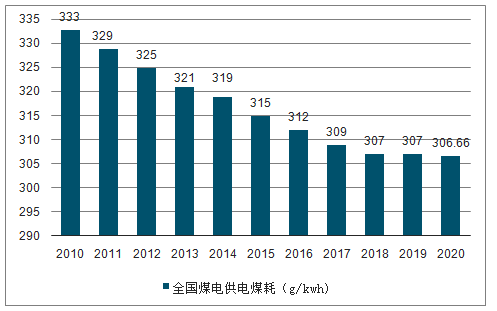

Nrog rau kev hloov kho ntawm kuv lub teb chaws lub zog qauv thiab kev ua kom zoo ntawm cov khoom siv hluav taws xob, kev ua haujlwm siab, huv si, thiab ib puag ncig tus phooj ywg loj-muaj peev xwm thiab high-parameter units tau dhau los ua qhov tseem ceeb. Los ntawm kev ua kom lub zog tsis muaj zog (siab thiab kub), nws tuaj yeem txhim kho cov thermal efficiency ntawm chav tsev, txo cov thee noj, thiab txo CO2 emissions. Tam sim no, txoj hauv kev tseem ceeb los txhim kho kev ua tau zoo ntawm cov khoom siv hluav taws xob thermal yog txhawm rau txhim kho chav tsis muaj zog thiab txhim kho supercritical (SC) thiab ultra-supercritical (USC) units. Tam sim no, muaj ntau tshaj 100 lab-kilowatt ultra-supercritical (USC) units muab tso rau hauv kuv lub teb chaws, nyob rau hauv qeb duas nyob rau hauv lub ntiaj teb no nyob rau hauv ob qho tib si kom muaj nuj nqis thiab tag nrho cov peev xwm.

Kev txheeb cais thiab kev kwv yees ntawm Coal Consumption ntawm Coal Power Supply hauv Suav teb los ntawm 2010 txog 2020

2.Main Chromium Molybdenum Steel Vuam Qws Khoom

Table 2 Performance zaub ntawm tus sawv cev pearlitic tshav kub-resistant steel electrodes

| Yam khoom | Cov khoom tseem ceeb | Kub ℃ * H | Mechanical cwj pwm | ||||

| Yield Mpa | Tensile Mpa | Txuas ntxiv % | poob siab J/℃ | ||||

| TSW-107 | 0.5% Mo | 620 * 1 | 477 ib | 570 ib | 24.0 Nws | 152/0 | - |

| TSW-207 | 0.5% Cr-0.5% Mo | 690 * 1 | 490 ib | 590 ua | 23.0 Nws | 143/0 | - |

| TSW-307 | 1.25% Cr-0.5% Mo | 690 * 1 | 490 ib | 590 ua | 23.0 Nws | 146/0 | - |

| TSW-317 | 1.25% Cr-0.5% Mo-V | 730 * 2 | 541 ib | 635 ib | 22.5 ib | 166/0 | - |

| TSW-407 | 2.25% Cr-1% Mo | 690 * 1 | 586 ib | 682 ib | 21.0 Nws | 142/0 | - |

| TSW-417 | 2.25% Cr-1% Mo-V | 720 * 8 | 556 ib | 657 ib | 21.0 Nws | 145/-18 | 120/- 30 |

| TSW-507 | 5% Cr-0.5% Mo | 740 * 1 | 490 ib | 605 | 23.0 Nws | 124/0 | - |

Nco tseg:

1. Peb lub tuam txhab tau tsim EXXXX-15, EXXXX-16, EXXXX-18 thiab lwm yam txheej slag series rau electrodes ntawm tib qib kom tau raws li cov kev xav tau ntawm kev lag luam sib txawv. Cov saum toj no tsuas yog qhia txog kev ua haujlwm ntawm EXXXX-15 electrodes.

3.2 Cov npe ntawm subcritical thiab super (ultra) tseem ceeb ferritic / martensitic tshav kub-resistant steel electrodes

| Yam khoom | STANDARD | Lub Cim Tseem Ceeb |

| TSW-707 | AWS A5.5 E8015-B8 GB/T 5118 E6215-9C1M | 9% Cr-1% Mo Carbon steel tub ntxhais hlau, lub ntsiab alloy muaj pes tsawg leeg yog hloov los ntawm txheej, haum rau thermal fais fab subcritical units, A213-T9, A335-P9 steel vuam (kev lag luam thiab siv tau, kev ua haujlwm zoo) |

| GER-91 Core hom | AWS A5.5 E9015-B91 GB/T 5118 E6215-9C1MV | 9% Cr-1% Mo-Nb-vn Tsim nyog rau thermal hwj chim tseem ceeb units, T / P 91 steel vuam, lub ntsiab alloy muaj pes tsawg leeg yog pauv los ntawm vuam core, kub microstructure thiab kev ua tau zoo stability. |

| GER-91M tshuaj tawv nqaij core | 9% Cr-1% Mo-Nb-VN Haum rau thermal hwj chim tseem ceeb units, T / P 91 steel vuam, lub ntsiab alloy muaj pes tsawg leeg yog pauv los ntawm vuam core, kub microstructure thiab kev ua tau zoo stability. | |

| GER-92 Core hom | AWS A5.5 E9015-B92 | 9% Cr-0.5% Mo-WV-Nb-N Haum rau thermal hwj chim supercritical units, T / P 92 steel vuam, lub ntsiab alloy muaj pes tsawg leeg yog hloov los ntawm cov tub ntxhais hlau, kub microstructure thiab kev ua tau zoo stability. |

| GER-93 | Peb tus qauv | 9% Cr-3% W-3% Co-Cu-V-Nb-B Nws yog qhov tsim nyog rau kev vuam ntawm qib siab supercritical G115 steel rau thermal zog tiam. Nws muaj cov qauv zoo thiab kev ua haujlwm ruaj khov ntawm qhov kub thiab txias. Lub zog ruaj khov yog 1.5 npaug ntawm P92 steel, thiab nws qhov kev tiv thaiv kub kub oxidation thiab corrosion yog zoo dua li ntawm P92 steel. |

Electrode Performance zaub

| Yam khoom | Cov khoom tseem ceeb | Kub ℃ * H | Mechanical cwj pwm | |||

| Yield Mpa | Tensile Mpa | Txuas ntxiv % | poob siab J | |||

| TSW-707 | 9% Cr-1% Mo | 740 * 1 | 540 | 670 ib | 24.0 Nws | 119.7 ib |

| GER-91 | 9% Cr-1% Mo-Nb-VN | 760 * 2 | 557 ib | 702 ib | 21.0 Nws | 96.3 ua |

| GER-91M | 9% Cr-1% Mo-Nb-VN | 760 * 2 | 553 ua | 701 ib | 22.5 ib | 81.0 ua |

| GER-92 | 9%Cr-0.5%Mo-WV-Nb-N | 760 * 2 | 596 ib | 706 ib | 21.5 ib | 103.0 Nws |

| GER-93 | 9% Cr-3% W-3% Co | 770 * 4 | 580 | 720 | 20.0 Nws | 77.7 ib |

Nco tseg:

1. GER-91M yog txheej hloov pauv, uas yog, vuam core yog cov pa roj carbon zoo tib yam core hlau, thiab lub ntsiab alloy yog hloov los ntawm txheej. Piv nrog GER-91 (core hloov pauv hom), nws muaj txiaj ntsig kev lag luam zoo dua thiab yog peb cov khoom tseem ceeb ntawm vuam rods rau supercritical thermal zog.

3.Lub 2015 version ntawm ASME tus qauv yuav tsum tau E9015-B91 electrode Mn + Ni≤1.4%, thiab 2017 version yuav tsum ≤1.2% rau lub hauv paus hlau. (2021 qhov tseeb version ntawm ASME txuas ntxiv siv 2015 version ntawm ASME cov kev cai muaj pes tsawg leeg rau E9015-B91 / B92 electrodes). Txhawm rau ua kom tau raws li kev xav tau ntawm kev lag luam, peb E9015-B91 thiab E9015-B92 vuam rods tau tsim ob hom khoom siv vuam: Mn + Ni≤1.4% thiab Mn + Ni≤1.2%. Vim tias yav tas los muaj kev lag luam xav tau ntau dua, cov saum toj no qhia tau hais tias 91/92 electrodes yog deposited hlau Mn + Ni≤1.2%.

4. Ua qauv qhia ntawm cov txheej txheem kev ntsuam xyuas rau ultra-supercritical electrodes

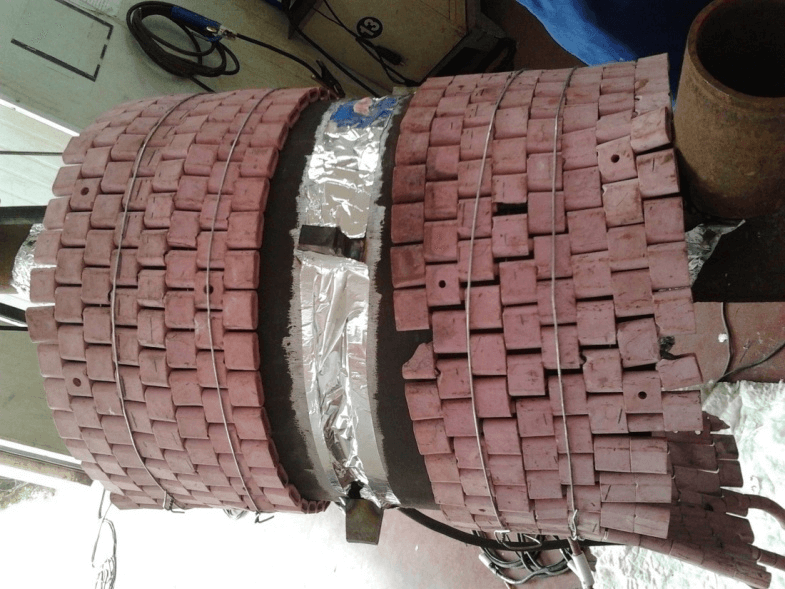

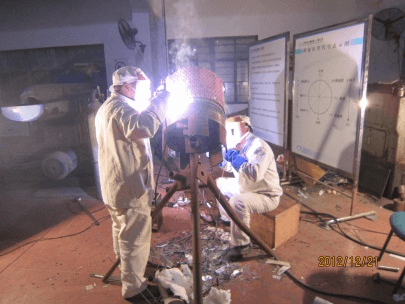

4.1 Txheej txheem tsim nyog ntawm P91/92 welded pob qij txha

6. Qhov zoo thiab cov yam ntxwv ntawm peb cov hluav taws kub-resistant steel electrodes rau chrome-molybdenum steel

1. Muaj ntau ntau yam thiab txhua yam

● Cov muaj pes tsawg leeg ntawm 0.5% Mo mus rau 9% Cr-3% W-3% Co.

● Siv qhov kub ntawm 500 ℃ txog 650 ℃.

● Cov xim sib txawv thiab txheej txheej (EXXXX-15, EXXXX-16, EXXXX-18) tuaj yeem siv rau ntau lub sijhawm (hom dav dav, muaj zog arc quab yuam hom rau cov kav dej siv hluav taws xob).

●Nws tuaj yeem ua tau raws li qhov yuav tsum tau ua ntawm feem ntau Cr-Mo steels.

2. Kev ua tau zoo

Cov khoom siv zoo heev, kev ua haujlwm kub zoo (siab kub creep thiab kub kub aging zog).

3. Kev ua haujlwm zoo

Cov electrode muaj kev tsim khoom zoo heev hauv txhua txoj haujlwm, ruaj khov arc combustion, zoo nruj thiab tshuab quab yuam, me me spatter, zoo fluidity, zoo nkauj weld zoo, thiab yooj yim slag tshem tawm tom qab vuam.

4. Kev lag luam ua lag luam

Kev koom tes nrog Suzhou lub koom haum thermal Engineering, thiab dhau qhov kev tshuaj xyuas ntawm "T/P 91/92 Localization Appraisal Meeting" nyob rau hauv 2015, thiab koom tes nrog loj domestic fais fab units xws li Shenhua Guohua thiab General Iron thiab Steel Research Institute los tsim 650 ° C. G115 steel txhawb kev vuam cov ntaub ntawv thiab cov txheej txheem, thiab tuav ntau lub rooj sib tham sib pauv khoom siv vuam.

More information send to E-mail: export@welding-honest.com

Post lub sij hawm: Dec-27-2022