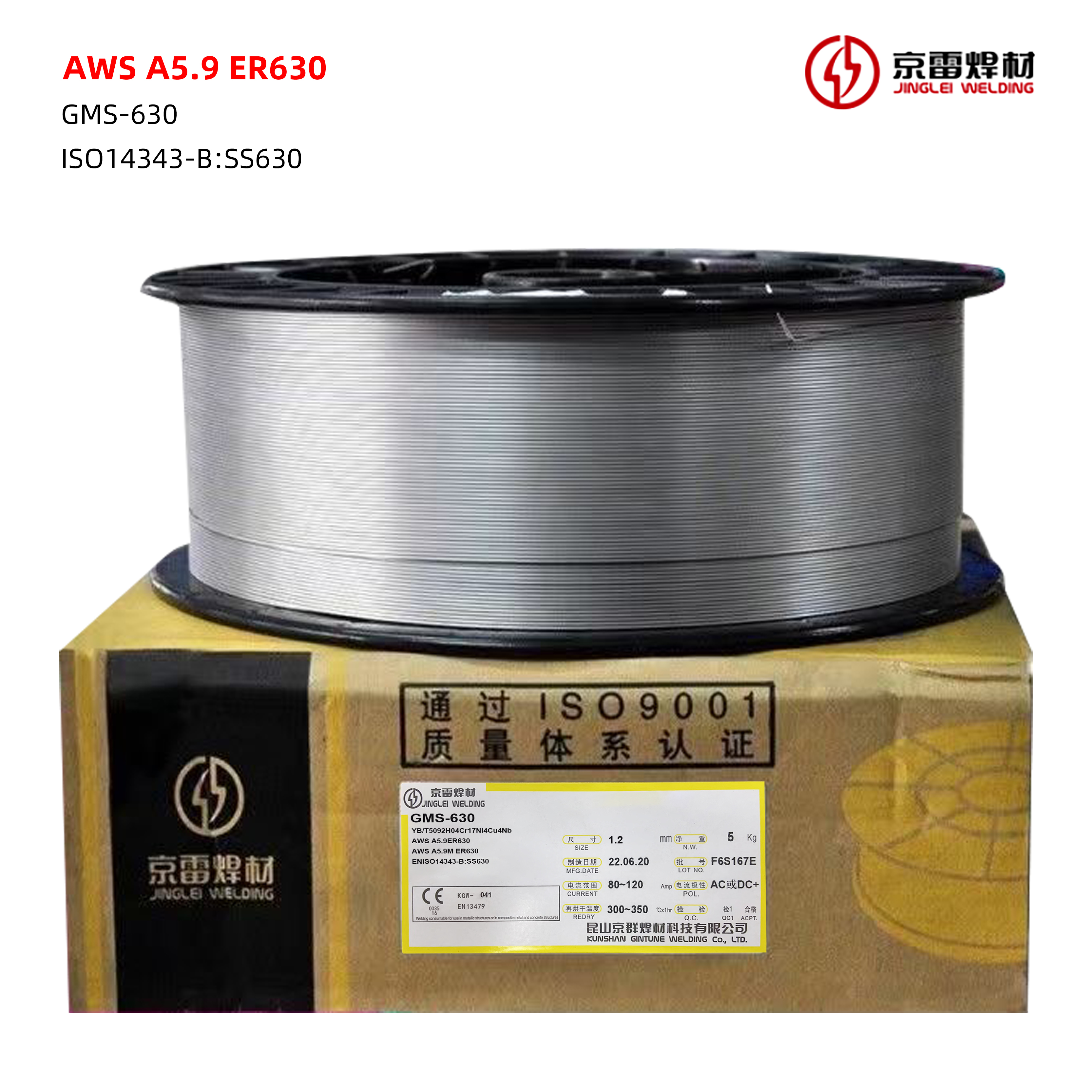

MIG Vuam Hlau Rau Stainless Hlau ER630 VLCC nkoj roj av soldering

WELDING TECHNOLOGY

Tsis txhob cia cov lus nug

Txuas ntxiv mus haunt koj

Arc instability

Unsightly molding

Tshaj tawm ntau dhau

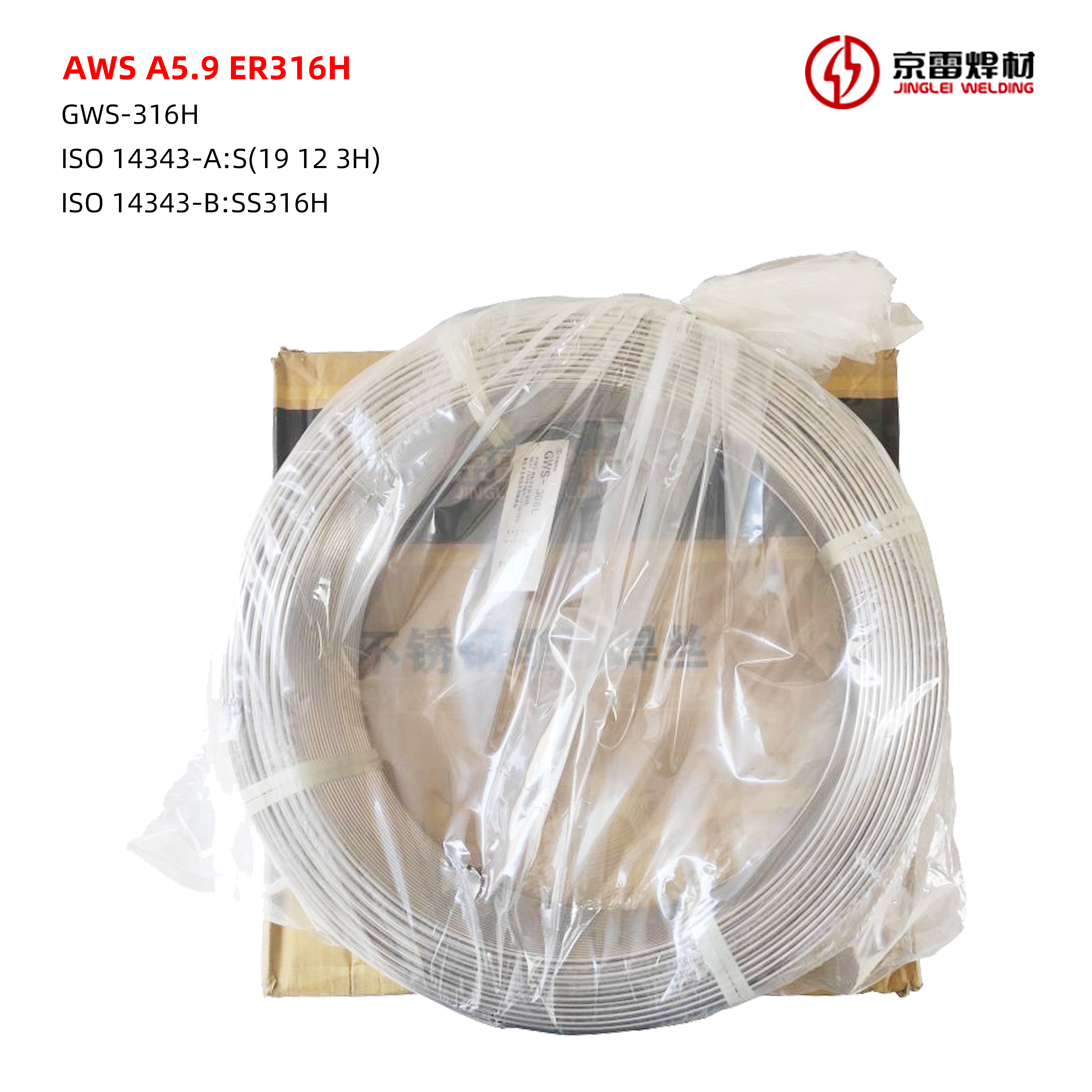

Nws yog feem ntau siv rau vuam pob golf

Cov khoom siv ntawm cov fused hlau yog ruaj khov

Ripple zoo

X-Ray tsim nyog tus nqi yog siab, cov hlau pub yog du

Lub arc yog ruaj khov, kev sib sau yog zoo nkauj, lub spatter yog tsawg, thiab cov txheej txheem vuam muaj kev ua tau zoo heev.

Yooj yim slagging

Khoom Parameter

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Lwm yam |

| GB/T RULES | 0.015 ib | 0.39 ib | 0.45 ib | 0.016 ib | 0.003 ib | 4.6 | 16.17 Nws | 0.05 Nws | ib: 0.19 |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | Elongation /% | IMAPACT VALUE J/℃ | Kev kho cua sov ° C * h | |||||

| GB/T RULES | - | 955 ua | 17 | - | 1040 * 1620 * 4 | |||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 0.8 ua | 1.0 | 1.2 | ||||

| ELECTRICITY (Amp) | H/W | 70-150 : kuv | 100-200 | 140-220 : kuv | |||

| O/W | 50-120 | 80-150 | 120-180 Nws | ||||

Kev them nyiaj yug Hoobkas

Cov khoom tsim nyog rau a

ntau yam kev siv

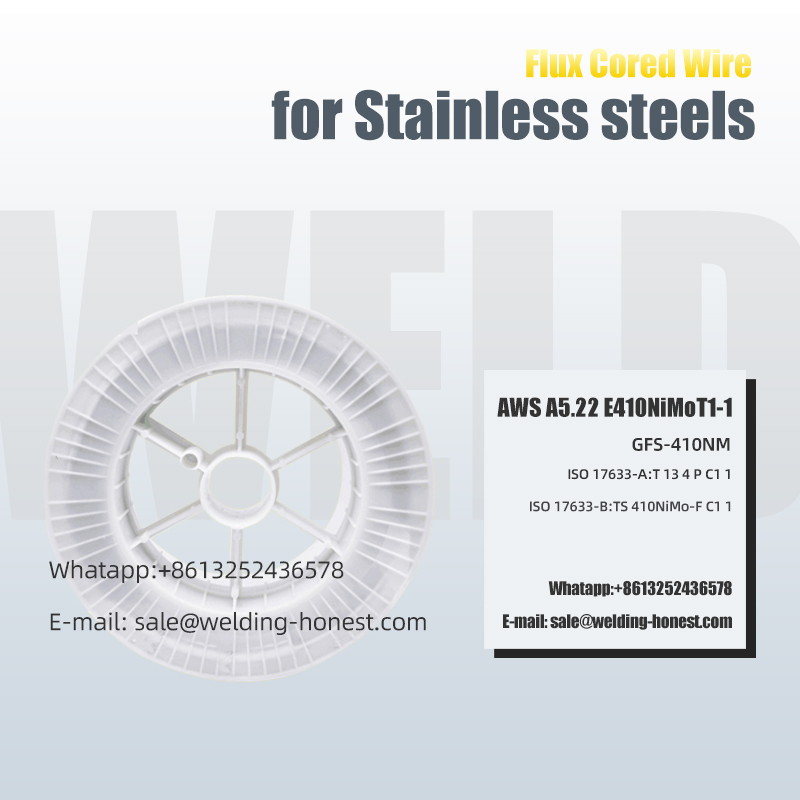

WELDING TECHNOLOGY

-

Cov pa roj carbon steel,

stainless hlau ntauwd welding

-

Tuam Tshoj thoob ntiaj teb

demethane Ntauwd

-

Xinjiang Chaw 2

Central Treatment Plant Project

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Lwm yam |

| GB/T RULES | 0.015 ib | 0.39 ib | 0.45 ib | 0.016 ib | 0.003 ib | 4.6 | 16.17 Nws | 0.05 Nws | ib: 0.19 |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | Elongation /% | IMAPACT VALUE J/℃ | Kev kho cua sov ° C * h | |||||

| GB/T RULES | - | 955 ua | 17 | - | 1040 * 1620 * 4 | |||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 0.8 ua | 1.0 | 1.2 | ||||

| ELECTRICITY (Amp) | H/W | 70-150 : kuv | 100-200 | 140-220 : kuv | |||

| O/W | 50-120 | 80-150 | 120-180 Nws | ||||

Sau koj cov lus ntawm no thiab xa tuaj rau peb