Tsawg-alloy steels phau ntawv electrode E8018-C2 Soldering data

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Ni | Cr | Mo | P | S |

| GB/T RULES | 0.12 | 1.25 | 0.80 ib | 3.00-3.75 Nws | - | - | 0.03 ib | 0.03 ib |

| AWS RULES | 0.12 | 1.25 | 0.80 ib | 3.00-3.75 Nws | - | - | 0.03 ib | 0.03 ib |

| EXAMPLE VALUE | 0.045 ib | 0.75 ib | 0.22 | 3.52 ib | 0.04 ib | 0.06 ib | 0.007 ib | 0.004 ib |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | Kev kho cua sov ° Cxh | |||||

| GB/T RULES | 460 | 550 | 27/-75 ib | 17 | 605 * 1 | |||||

| AWS RULES | 460 | 550 | 27/-75 ib | 19 | 605 * 1 | |||||

| EXAMPLE VALUE | 495 ib | 600 | 100/-75 | 26 | 605 * 1 | |||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 350 | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 hli | ||||

| ELECTRICITY (Amp) | H/W | 80-110 : kuv | 100-130 Nws | 130-180 Nws | 170-210 : kuv | |||

| O/W | 60-100 | 80-120 : kuv | 120-160 : kuv | - | ||||

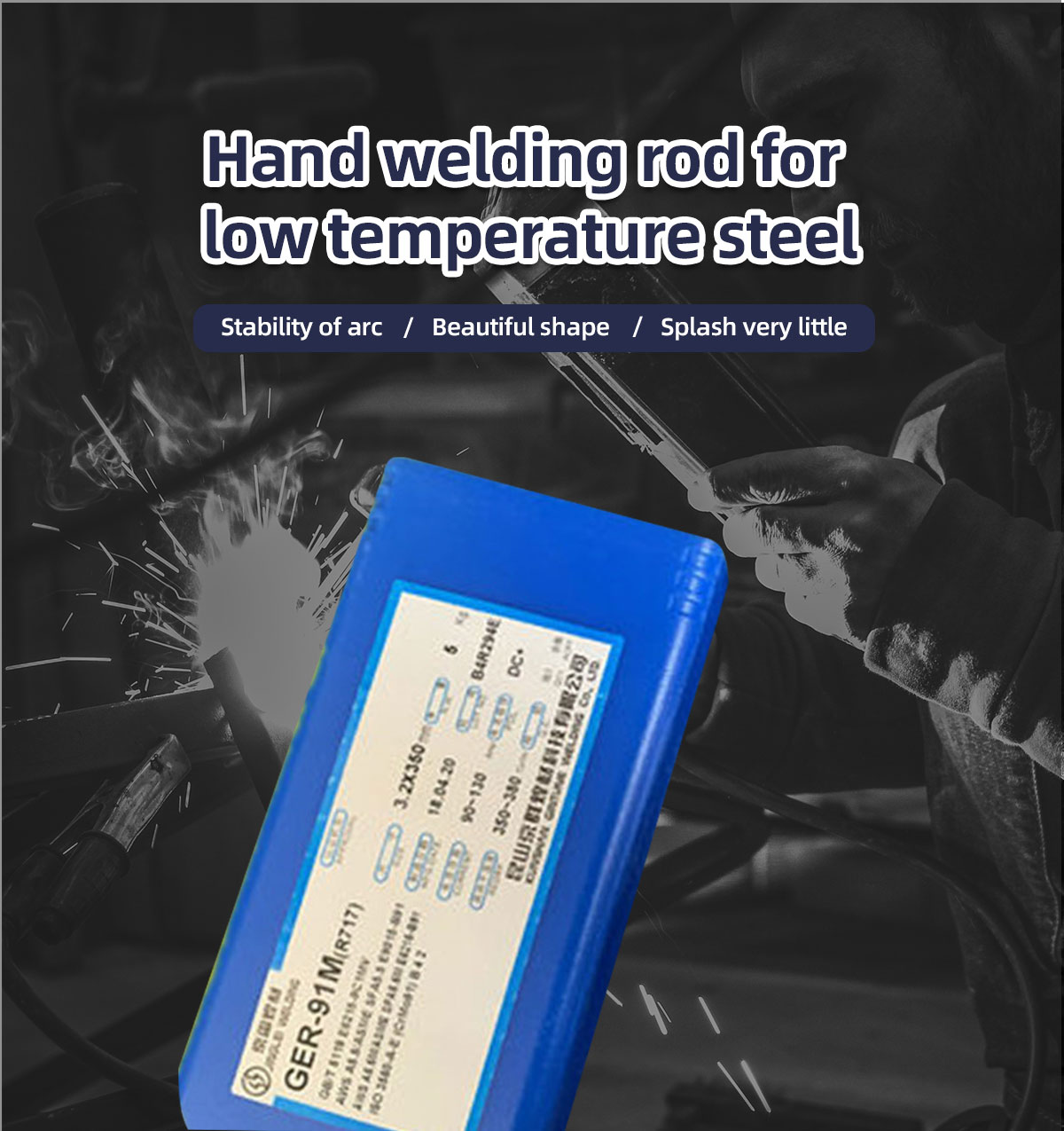

Hlau hmoov tsis tshua muaj hydrogen hom tes electrode.

Vim tias qhov sib ntxiv ntawm cov hmoov hlau, qhov kev ua haujlwm melting ntau dua, qhov cuam tshuam toughness ntawm cov hlau molten ntawm -75 ℃.

Ruaj khov arc, tsis tshua muaj txaws, zoo tsim, yooj yim slag tshem tawm, X-Ray kev ua tau zoo heev.

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Ni | Cr | Mo | P | S |

| GB/T RULES | 0.12 | 1.25 | 0.80 ib | 3.00-3.75 Nws | - | - | 0.03 ib | 0.03 ib |

| AWS RULES | 0.12 | 1.25 | 0.80 ib | 3.00-3.75 Nws | - | - | 0.03 ib | 0.03 ib |

| EXAMPLE VALUE | 0.045 ib | 0.75 ib | 0.22 | 3.52 ib | 0.04 ib | 0.06 ib | 0.007 ib | 0.004 ib |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | Kev kho cua sov ° Cxh | |||||

| GB/T RULES | 460 | 550 | 27/-75 ib | 17 | 605 * 1 | |||||

| AWS RULES | 460 | 550 | 27/-75 ib | 19 | 605 * 1 | |||||

| EXAMPLE VALUE | 495 ib | 600 | 100/-75 | 26 | 605 * 1 | |||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 350 | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 hli | ||||

| ELECTRICITY (Amp) | H/W | 80-110 : kuv | 100-130 Nws | 130-180 Nws | 170-210 : kuv | |||

| O/W | 60-100 | 80-120 : kuv | 120-160 : kuv | - | ||||

Sau koj cov lus ntawm no thiab xa tuaj rau peb