Tsawg-alloy steels Phau ntawv electrode E8015-C1 weld fabrication kev twb kev txuas

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S |

| GB/T RULES | 0.12 | 1.25 | 0.80 ib | - | 2.00-2.75 Nws | - | 0.03 ib | 0.03 ib |

| AWS RULES | 0.12 | 1.25 | 0.80 ib | - | 2.00-2.75 Nws | - | 0.03 ib | 0.03 ib |

| EXAMPLE VALUE | 0.068 ib | 0.93 ua | 0.26 | 0.02 ib | 2.31 Nws | 0.11 | 0.008 ib | 0.006 ib |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | Kev kho cua sov ° Cxh | |||||

| GB/T RULES | 460 | 550 | 27/-50 Nws | 17 | 605 * 1 | |||||

| AWS RULES | 460 | 550 | 27/-50 Nws | 19 | 605 * 1 | |||||

| EXAMPLE VALUE | 488 ib | 591 ib | 120/-60 | 26 | 605 * 1 | |||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 350 | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 hli | ||||

| ELECTRICITY (Amp) | H/W | 70-110 : kuv | 100-140 Nws | 140-180 : kuv | 180-230 : kuv | |||

| O/W | 60-90 | 90-130 : kuv | 120-160 : kuv | - | ||||

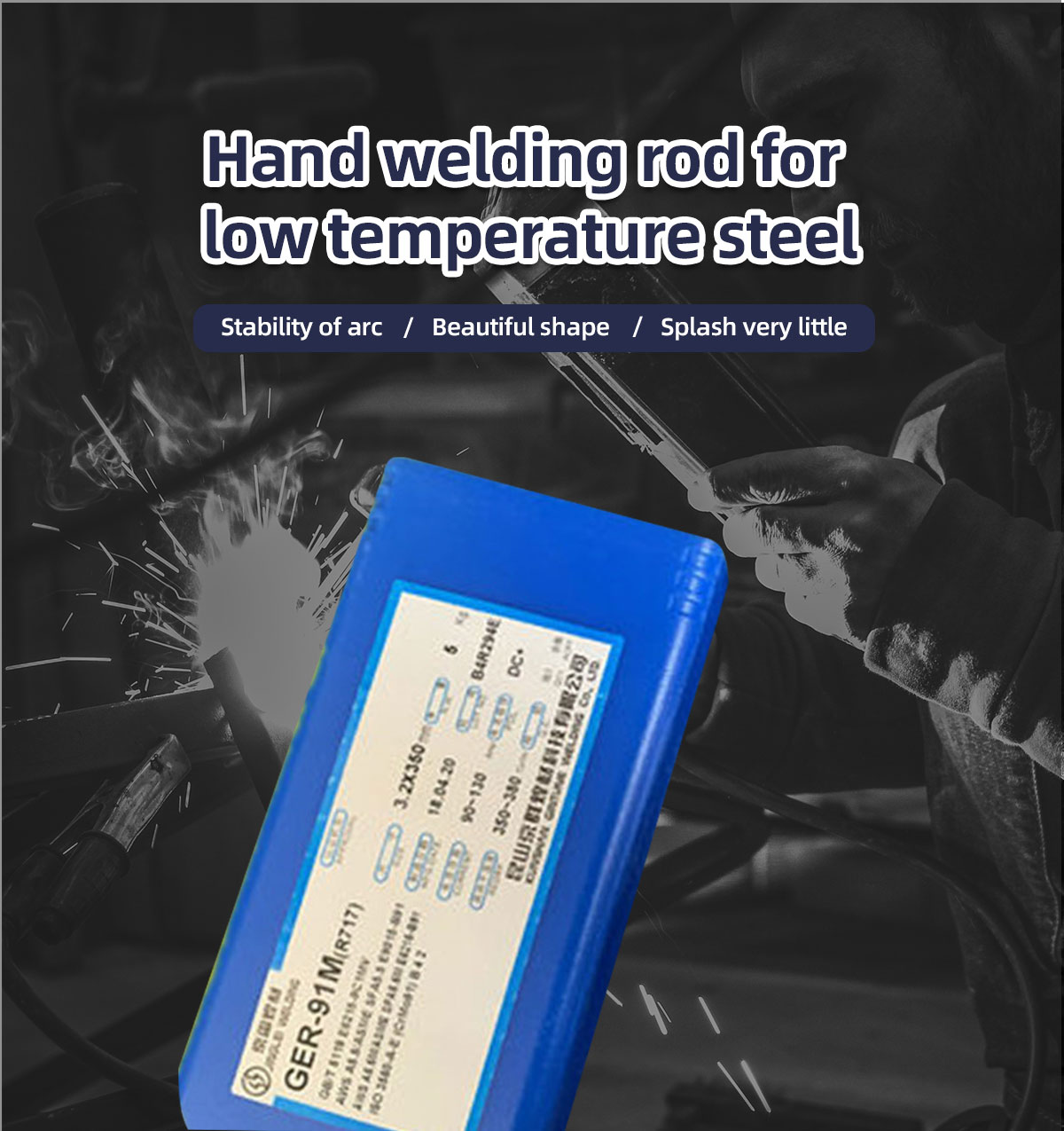

Tsawg sodium hydrogen hom tes electrode, ntawm -60 ° C ua haujlwm kub, qhov cuam tshuam ntawm cov hlau molten zoo heev.

-70 ° C pov tseg muaj qhov kub thiab txias toughness.

Ruaj khov arc, tsis tshua muaj txaws, zoo tsim, yooj yim slag tshem tawm, X-Ray kev ua tau zoo heev.

Hudong LNG Carrier

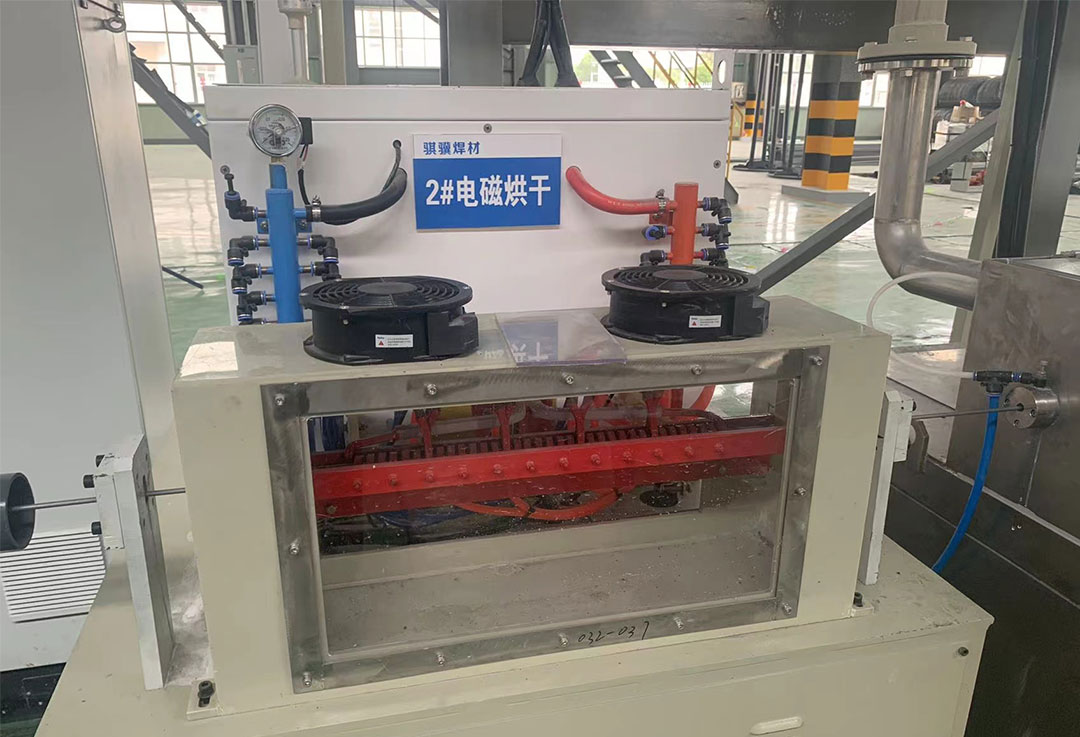

Peb lub qhov rooj 2# tsis ua haujlwm

Sinopec refining thiab Chemical Project

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S |

| GB/T RULES | 0.12 | 1.25 | 0.80 ib | - | 2.00-2.75 Nws | - | 0.03 ib | 0.03 ib |

| AWS RULES | 0.12 | 1.25 | 0.80 ib | - | 2.00-2.75 Nws | - | 0.03 ib | 0.03 ib |

| EXAMPLE VALUE | 0.068 ib | 0.93 ua | 0.26 | 0.02 ib | 2.31 Nws | 0.11 | 0.008 ib | 0.006 ib |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | Kev kho cua sov ° Cxh | |||||

| GB/T RULES | 460 | 550 | 27/-50 Nws | 17 | 605 * 1 | |||||

| AWS RULES | 460 | 550 | 27/-50 Nws | 19 | 605 * 1 | |||||

| EXAMPLE VALUE | 488 ib | 591 ib | 120/-60 | 26 | 605 * 1 | |||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 350 | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 hli | ||||

| ELECTRICITY (Amp) | H/W | 70-110 : kuv | 100-140 Nws | 140-180 : kuv | 180-230 : kuv | |||

| O/W | 60-90 | 90-130 : kuv | 120-160 : kuv | - | ||||

Sau koj cov lus ntawm no thiab xa tuaj rau peb