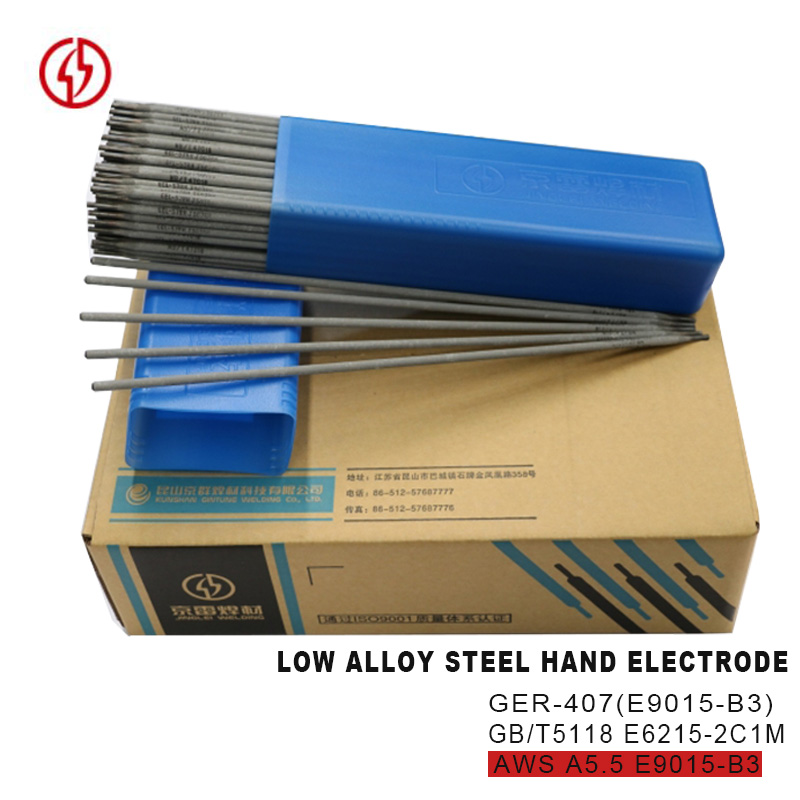

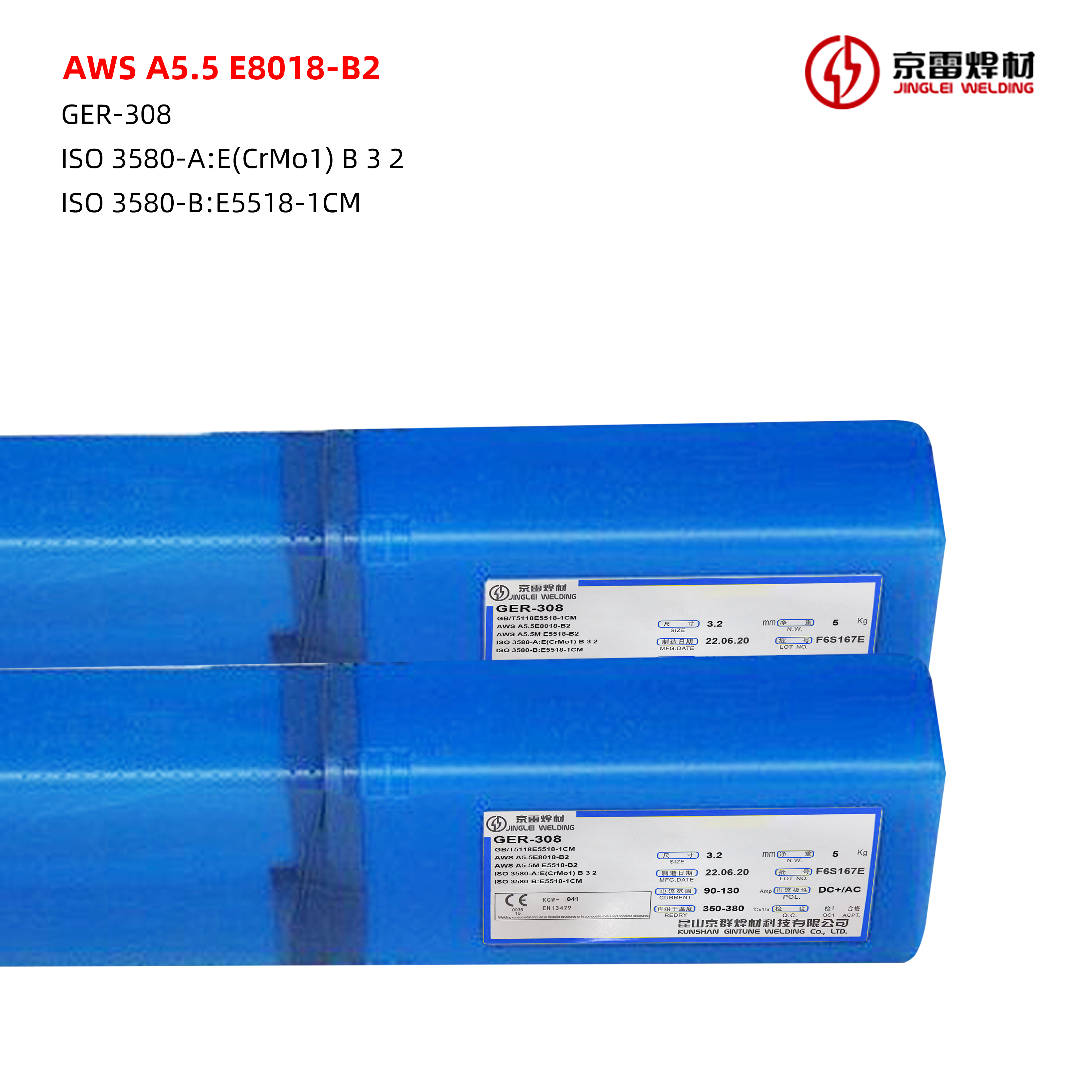

Tsawg-alloy steels Phau ntawv electrode E7016-B2L hlau Jointing kev twb kev txuas

Hlau hmoov tsis tshua muaj hydrogen potassium hom tes vuam pas nrig, ruaj khov arc

Tsawg splash, zoo molding, yooj yim tshem tawm slag X-Ray kev ua tau zoo

Cov khoom siv ruaj khov, muaj kev cuam tshuam siab toughness tuaj yeem tswj tau raws li kev kho cua sov

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Si | Mn | P | S | Ni | Cr | Mo | Lwm yam |

| GB/T RULES | 0.037 ib | 0.28 ib | 0.82 ib | 0.011 ib | 0.008 ib | 0.012 ib | 1.21 | 0.48 ib | - |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | Elongation (%) | IMAPACT VALUE J/℃ | Kev kho cua sov ° C * h | |||||

| GB/T RULES | 480 | 575 ib | 24 | 170 / Qhov kub thiab txias | 690 * 1 | |||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 hli | ||||

| ELECTRICITY (Amp) | H/W | 90-130 : kuv | 140-190 : kuv | 190-240 : kuv | |||

| O/W | 80-120 : kuv | 120-160 : kuv | - | ||||

-

Mei Jin Hua Sheng

glycol hluavtaws ntauwd

-

Hainan Huasheng

phenol rov qab ntauwd

-

GDS-2209/GXS-E330

tube surfacing welding site

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Si | Mn | P | S | Ni | Cr | Mo | Lwm yam |

| GB/T RULES | 0.037 ib | 0.28 ib | 0.82 ib | 0.011 ib | 0.008 ib | 0.012 ib | 1.21 | 0.48 ib | - |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | Elongation (%) | IMAPACT VALUE J/℃ | Kev kho cua sov ° C * h | |||||

| GB/T RULES | 480 | 575 ib | 24 | 170 / Qhov kub thiab txias | 690 * 1 | |||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 hli | ||||

| ELECTRICITY (Amp) | H/W | 90-130 : kuv | 140-190 : kuv | 190-240 : kuv | |||

| O/W | 80-120 : kuv | 120-160 : kuv | - | ||||

Sau koj cov lus ntawm no thiab xa tuaj rau peb