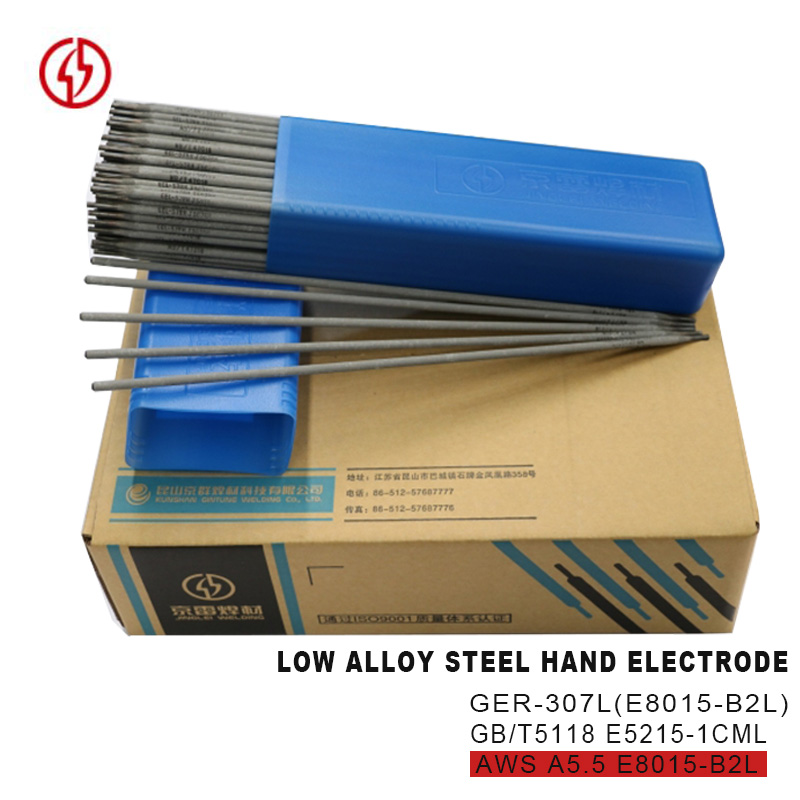

Tsawg-alloy steels Phau ntawv electrode E7016-A1 Soldering accessories

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Si | Mn | P | S | Ni | Cr | Mo | Lwm yam |

| GB/T RULES | 0.065 ib | 0.35 Nws | 0.65 ib | 0.015 ib | 0.01 ib | 0.03 ib | 0.04 ib | 0.5 | - |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | Elongation (%) | IMAPACT VALUE J/℃ | Kev kho cua sov ° C * h | |||||

| GB/T RULES | 460 | 560 | 27 | 130 / Qhov kub thiab txias | 620 * 1 | |||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 hli | ||||

| ELECTRICITY (Amp) | H/W | 90-130 : kuv | 140-190 : kuv | 190-240 : kuv | |||

| O/W | 80-120 : kuv | 120-160 : kuv | - | ||||

Tsawg hydrogen potassium hom tes vuam pas nrig, ntxiv 0.5% Mo, txhim kho lub zog vuam thiab corrosion kuj

Ruaj khov arc, tsis tshua muaj txaws, zoo molding, yooj yim slag tshem tawm

X-Ray kev ua tau zoo heev.

-

Sino-russian sab hnub tuaj pem hauv ntej

Harbin hluav taws xob peb lub rooj vag CMT

-

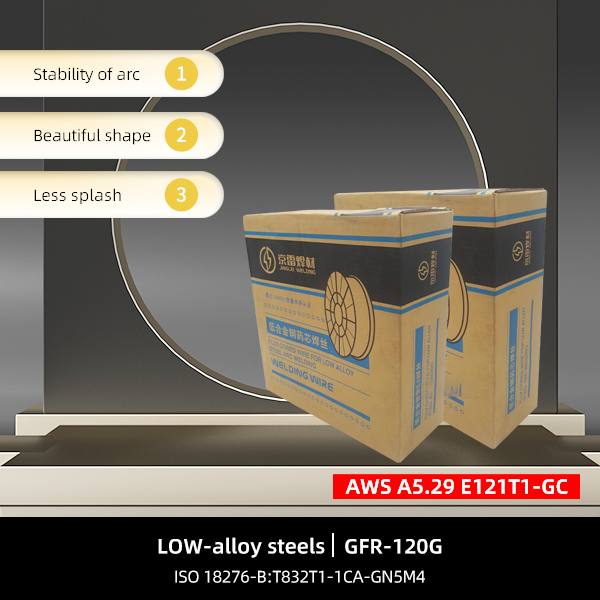

Vuam cov ntaub ntawv rau ntim

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Si | Mn | P | S | Ni | Cr | Mo | Lwm yam |

| GB/T RULES | 0.065 ib | 0.35 Nws | 0.65 ib | 0.015 ib | 0.01 ib | 0.03 ib | 0.04 ib | 0.5 | - |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | Elongation (%) | IMAPACT VALUE J/℃ | Kev kho cua sov ° C * h | |||||

| GB/T RULES | 460 | 560 | 27 | 130 / Qhov kub thiab txias | 620 * 1 | |||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 hli | ||||

| ELECTRICITY (Amp) | H/W | 90-130 : kuv | 140-190 : kuv | 190-240 : kuv | |||

| O/W | 80-120 : kuv | 120-160 : kuv | - | ||||

Sau koj cov lus ntawm no thiab xa tuaj rau peb