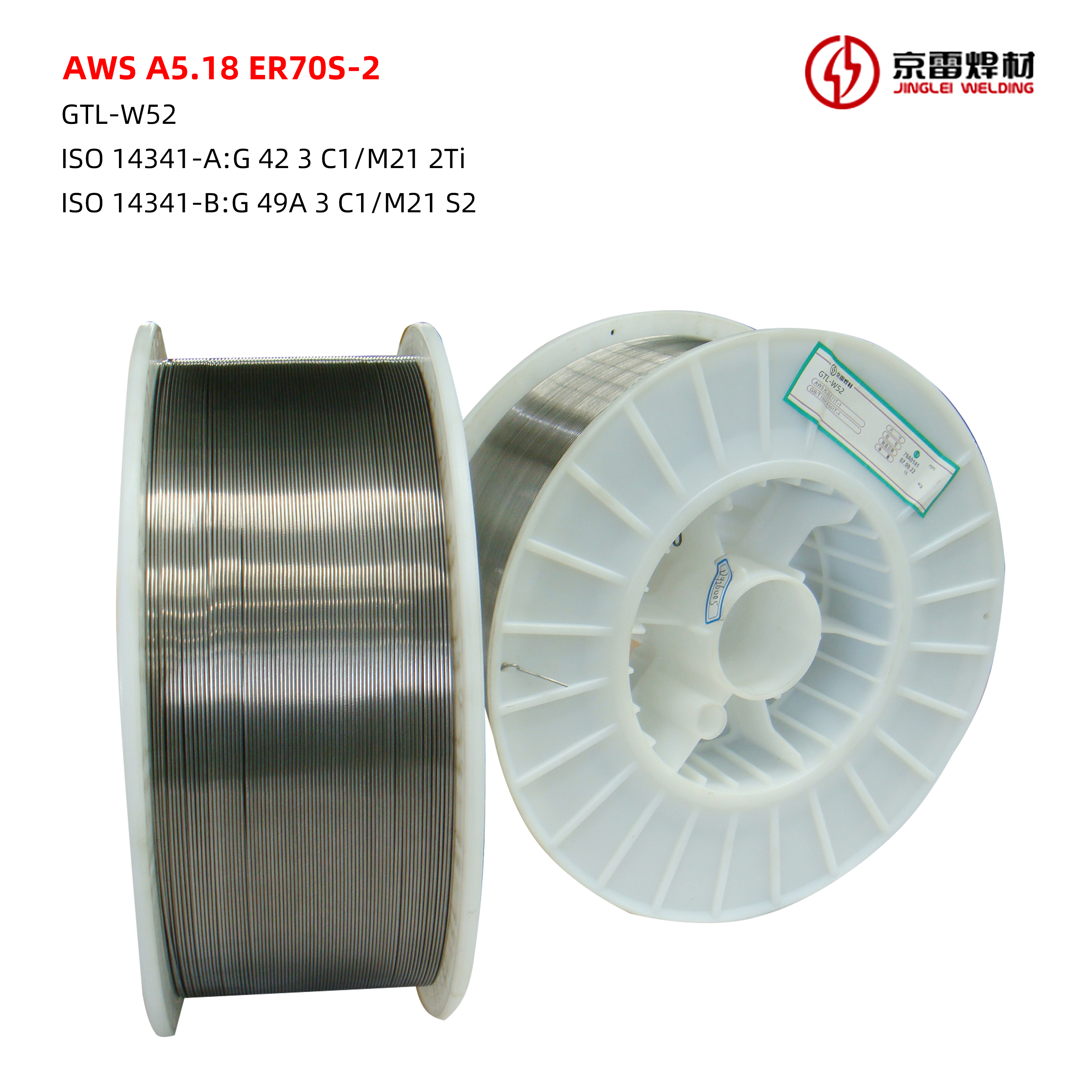

High Carbon steels Khoom hlau ER70S-2 weld fabrication accessories

Haum rau vuam ntawm cov kav dej, lub nkoj siab, kev lag luam petrochemical thiab lwm yam.

Dab tsi yog characieristics?

●Vim yog qhov sib ntxiv ntawm AI, Ti, Zr thiab lwm yam hlau, tuaj yeem siv los txuas xeb thiab av rau saum npoo ntawm cov hlau; Kev noj cov hlau du, ruaj khov arc, zoo nkauj sib sau, zoo ntws ntawm molten hlau, tsis tshua muaj txaws, nrog zoo heev vuam txheej txheem kev ua tau zoo; Molten hlau muaj cov khoom siv kho tshuab ruaj khov thiab zoo heev uas tsis muaj qhov kub thiab txias ua haujlwm

Khoom Parameter

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Si | Mn | P | S | Ni | Cr | Mo | Lwm yam |

| GB/T RULES | 0.053 ua | 0.51 ib | 1.08 Nws | 0.01 ib | 0.003 ib | 0.01 ib | 0.04 ib | 0.06 ib | Ti: 0.10 Al: 0.07 Zr: 0.06 |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | Kev kho cua sov ° C * h | ||||

| GB/T RULES | 475 ib | 550 | 32 | 80/- 30 | AW | ||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 1 | 1.2 | 1.6 | |||||

| ELECTRICITY (Amp) | H/W | 80-250 | 100-350 | 250-300 Nws | ||||

| O/W | 70-120 : kuv | 80-150 | ||||||

Hom kev thauj mus los

●Tsav tsheb thauj mus los

●Kev xa khoom

Peb lub tsev khaws khoom

Peb koom nrog qhov kev pab cuam

●Kev siv hluav taws xob thermal

●Shanghai Morimatsu Cia Tank

Peb cov khoom rau lub ntiaj teb

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Si | Mn | P | S | Ni | Cr | Mo | Lwm yam |

| GB/T RULES | 0.053 ua | 0.51 ib | 1.08 Nws | 0.01 ib | 0.003 ib | 0.01 ib | 0.04 ib | 0.06 ib | Ti: 0.10 Al: 0.07 Zr: 0.06 |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | Kev kho cua sov ° C * h | ||||

| GB/T RULES | 475 ib | 550 | 32 | 80/- 30 | AW | ||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 1 | 1.2 | 1.6 | |||||

| ELECTRICITY (Amp) | H/W | 80-250 | 100-350 | 250-300 Nws | ||||

| O/W | 70-120 : kuv | 80-150 | ||||||

Sau koj cov lus ntawm no thiab xa tuaj rau peb