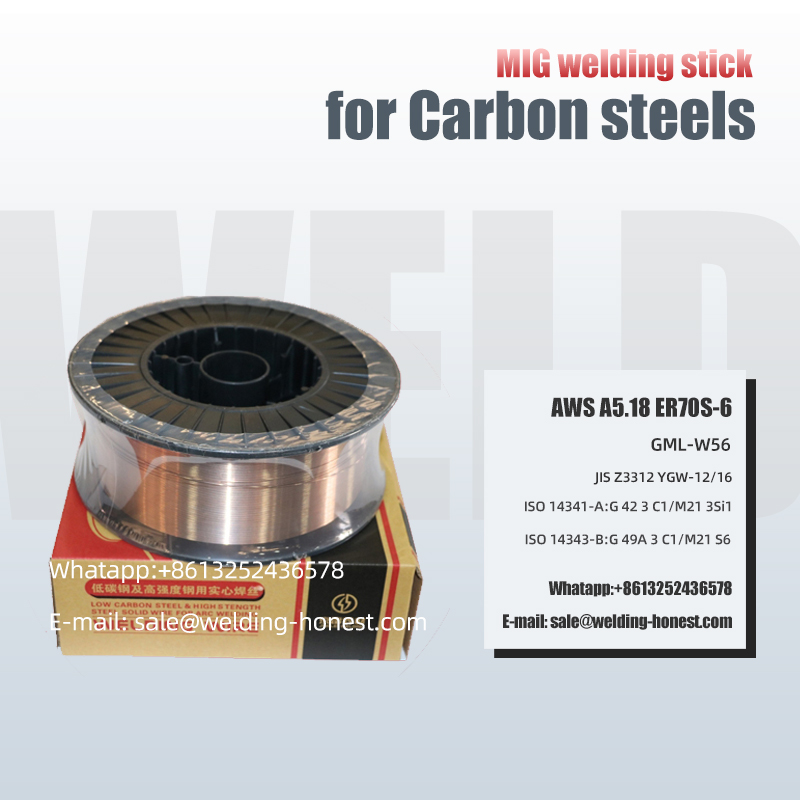

High Carbon steels MIG ER70S-6 Foob ua

Haum rau tsheb, choj, kev tsim kho, nkoj tsim, tshuab, siab nkoj, boiler thiab lwm yam vuam zaus, kuj siv tau rau phaj, yeeb nkab vuam.

Tus qauv peb ntsib: GB/T8110 G 49A 3 C1/M21 S6 N, AWS A5.18 ER70S-6 & A5.18M ER49S-6, ISO14341-A:G 42 3 C1/M21 3Si1, ISO14341-B:G 49 3 C1/M21 S6, JIS Z3312 YGW-12/16.

Dab tsi yog cov

yam ntxwv?

●Nws tuaj yeem siv rau qhov loj welding tam sim no ntau yam, thiab nyob rau hauv qhov qis tam sim no vuam arc stability.

●Tsawg spark splash, weld tsim zoo nkauj.

●Weld hlau porosity rhiab heev yog tsawg.

●Nws muaj cov khoom siv zoo heev.

Khoom Parameter

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULES | 0.06-0.15 dr hab | 1.40-1.85 Nws | 0.80-1.15 Nws | 0.15 | 0.15 | 0.15 | 0.025 ib | 0.025 ib | 0.50 ib |

| AWS RULES | 0.06-0.15 dr hab | 1.40-1.85 Nws | 0.80-1.15 Nws | 0.15 | 0.15 | 0.15 | 0.025 ib | 0.035 ib | 0.50 ib |

| EXAMPLE VALUE | 0.075 ib | 1.450 Nws | 0.83 ib | 0.02 ib | 0.02 ib | 0.001 ib | 0.015 ib | 0.010 ib | 0.020 ib |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 390 | 490-670 : kuv | AW | 27/-30 Nws | 18 | ||||

| AWS RULES | 400 | 490 ib | AW | 27/-30 Nws | 22 | ||||

| EXAMPLE VALUE | 455 | 560 | AW | 73/-30 ib | 28 | ||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 1 | 1.2 | 1.6 | ||||

| ELECTRICITY (Amp) | H/W | 80-250 | 100-350 | 250-300 Nws | |||

| O/W | 70-120 : kuv | 80-150 | |||||

Saib ntawm txoj kev

peb thauj

●Tsav tsheb thauj mus los

●Kev xa khoom

Saib

peb wareno

Cov phiaj xwm

peb koom nrog

●Tuam Tshoj Ntiaj teb no demethane Ntauwd

●GDS-2209/GXS-E330 tube surfacing site

Peb cov khoom

mus rau lub ntiaj teb no

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULES | 0.06-0.15 dr hab | 1.40-1.85 Nws | 0.80-1.15 Nws | 0.15 | 0.15 | 0.15 | 0.025 ib | 0.025 ib | 0.50 ib |

| AWS RULES | 0.06-0.15 dr hab | 1.40-1.85 Nws | 0.80-1.15 Nws | 0.15 | 0.15 | 0.15 | 0.025 ib | 0.035 ib | 0.50 ib |

| EXAMPLE VALUE | 0.075 ib | 1.450 Nws | 0.83 ib | 0.02 ib | 0.02 ib | 0.001 ib | 0.015 ib | 0.010 ib | 0.020 ib |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 390 | 490-670 : kuv | AW | 27/-30 Nws | 18 | ||||

| AWS RULES | 400 | 490 ib | AW | 27/-30 Nws | 22 | ||||

| EXAMPLE VALUE | 455 | 560 | AW | 73/-30 ib | 28 | ||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 1 | 1.2 | 1.6 | ||||

| ELECTRICITY (Amp) | H/W | 80-250 | 100-350 | 250-300 Nws | |||

| O/W | 70-120 : kuv | 80-150 | |||||

Sau koj cov lus ntawm no thiab xa tuaj rau peb