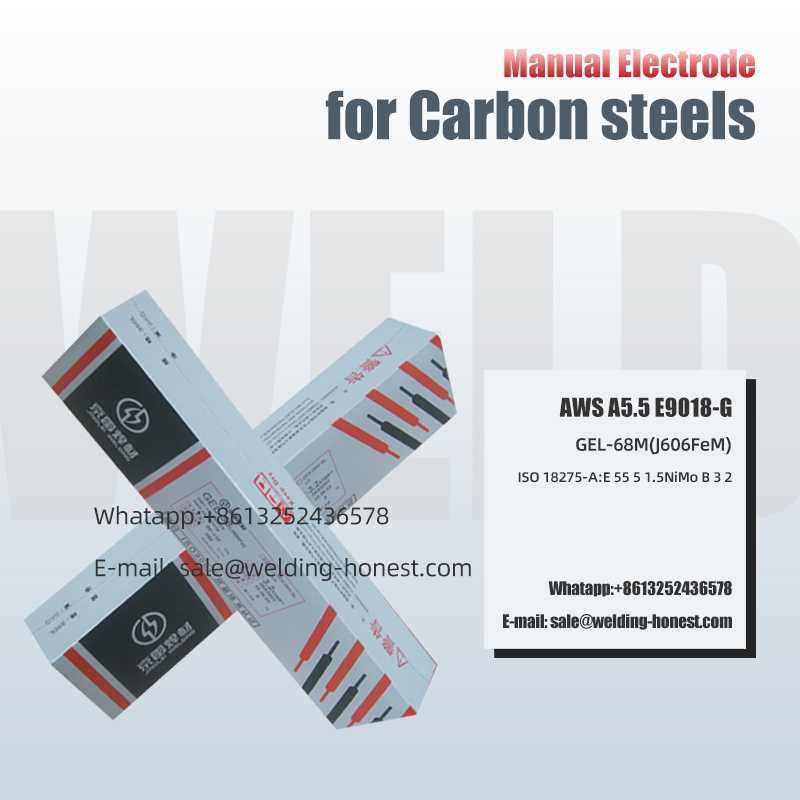

High Carbon Steels Phau Ntawv Electrode E9018-G cargo nkoj vuam hlau kauj

Haum rau cov hlau tsis tshua muaj kub hlau, nruab nrab carbon steel vuam, xws li kev tsim kho tshuab, chaw nres nkoj machinery thiab lwm lub sijhawm.

Tus qauv peb ntsib: GB/T32533 E5918-G P, AWS A5.5 E9018-G & A5.5M E6218-G, ISO18275-A:E 55 5 1.5NiMo B 3 2, ISO18275-B: E6218-G P.

Dab tsi yog cov

yam ntxwv?

●Hlau hmoov tsis tshua muaj hydrogen tes electrode, high efficiency, ruaj khov arc, me me txaws.

●Zoo sib sau, yooj yim desagging.

●X-ray kev ua tau zoo heev.

●Nws muaj kev ua haujlwm zoo tawg thiab ruaj khov mechanical zog.

Khoom Parameter

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | - | ≥1.00 Nws | ≥0.80 | ≥0.30 Nws | ≥0.50 | ≥0.20 | - | - | ≥0.10 |

| AWS RULES | - | ≥1.01 | ≥0.80 | ≥0.30 Nws | ≥0.50 | ≥0.20 | 0.030 Nws | 0.030 Nws | ≥0.11 |

| EXAMPLE VALUE | 0.068 ib | 1.258 ib | 0.28 ib | 0.03 ib | 1.65 ib | 0.42 ib | 0.011 ib | 0.007 ib | 0.01 ib |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 490 ib | 590 ua | 620 * 1 | 27/-20 ib | 16 | ||||

| AWS RULES | 530 | 620 | 620 * 1 | - | 17 | ||||

| EXAMPLE VALUE | 600 | 685 ib | 620 * 1 | 85/-50 | 24 | ||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 350 | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 hli | |||||

| ELECTRICITY (Amp) | H/W | 80-110 : kuv | 100-130 Nws | 130-180 Nws | 180-230 : kuv | ||||

| O/W | 50-80 | 90-120 : kuv | 130-160 : kuv | - | |||||

Saib ntawm txoj kev

peb thauj

●Tsav tsheb thauj mus los

●Kev xa khoom

Saib

peb wareno

Cov phiaj xwm

peb koom nrog

●300,000-ton bulk carrier

●2.3 lab barrels ntawm SBM Fast4ward FPSO

Peb cov khoom

mus rau lub ntiaj teb no

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | - | ≥1.00 Nws | ≥0.80 | ≥0.30 Nws | ≥0.50 | ≥0.20 | - | - | ≥0.10 |

| AWS RULES | - | ≥1.01 | ≥0.80 | ≥0.30 Nws | ≥0.50 | ≥0.20 | 0.030 Nws | 0.030 Nws | ≥0.10 |

| EXAMPLE VALUE | 0.070 ib | 1.55 ib | 0.32 ib | 0.031 ib | 0.82 ib | 0.31 Nws | 0.012 ib | 0.005 ib | 0.03 ib |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 490 ib | 590 ua | 620 * 1 | 27/-20 ib | 16 | ||||

| AWS RULES | 530 | 620 | 620 * 1 | - | 17 | ||||

| EXAMPLE VALUE | 585 ib | 670 ib | 620 * 1 | 85/-50 | 24 | ||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 350 | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 hli | |||||

| ELECTRICITY (Amp) | H/W | 80-110 : kuv | 110-130 : kuv | 130-180 Nws | 180-230 : kuv | ||||

| O/W | 50-80 | 90-120 : kuv | 130-160 : kuv | - | |||||

Sau koj cov lus ntawm no thiab xa tuaj rau peb