High Carbon steels Phau ntawv electrode E9015-G weld fabrication data

Daim ntawv thov

Haum rau cov hlau tsis tshua muaj hlau, nruab nrab thiab siab carbon steel thiab casting steel vuam, xws li kev siv tshuab, chaw nres nkoj machinery thiab lwm lub sijhawm. Kuj tseem siv hauv X80 pipeline steel.

Tus qauv peb ntsib: GB/T32533 E5915-G P, AWS A5.5 E9015-G & A5.5M E6215-G, ISO18275-A:E 55 5 ZMn1Ni0.3Mo B 4 2, ISO 18275-B: E6215-G P.

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | - | ≥1.00 Nws | ≥0.80 | ≥0.30 Nws | ≥0.50 | ≥0.20 | - | - | ≥0.10 |

| AWS RULES | - | ≥1.01 | ≥0.80 | ≥0.30 Nws | ≥0.50 | ≥0.20 | 0.030 Nws | 0.030 Nws | ≥0.10 |

| EXAMPLE VALUE | 0.070 ib | 1.55 ib | 0.32 ib | 0.031 ib | 0.82 ib | 0.31 Nws | 0.012 ib | 0.005 ib | 0.03 ib |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 490 ib | 590 ua | 620 * 1 | 27/-20 ib | 16 | ||||

| AWS RULES | 530 | 620 | 620 * 1 | - | 17 | ||||

| EXAMPLE VALUE | 585 ib | 670 ib | 620 * 1 | 85/-50 | 24 | ||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 350 | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 hli | |||||

| ELECTRICITY (Amp) | H/W | 80-110 : kuv | 110-130 : kuv | 130-180 Nws | 180-230 : kuv | ||||

| O/W | 50-80 | 90-120 : kuv | 130-160 : kuv | - | |||||

Peculiarity

Tsawg sodium hydrogen electrode, ruaj khov arc, me me txaws, zoo sib sau.

Ib qho yooj yim desagging, X-ray kev ua tau zoo.

High toughness, tsis tshua muaj hydrogen, zoo tawg kuj, mechanical stability.

Qhia kom meej

Stability ntawm arc

Yooj yim slagging

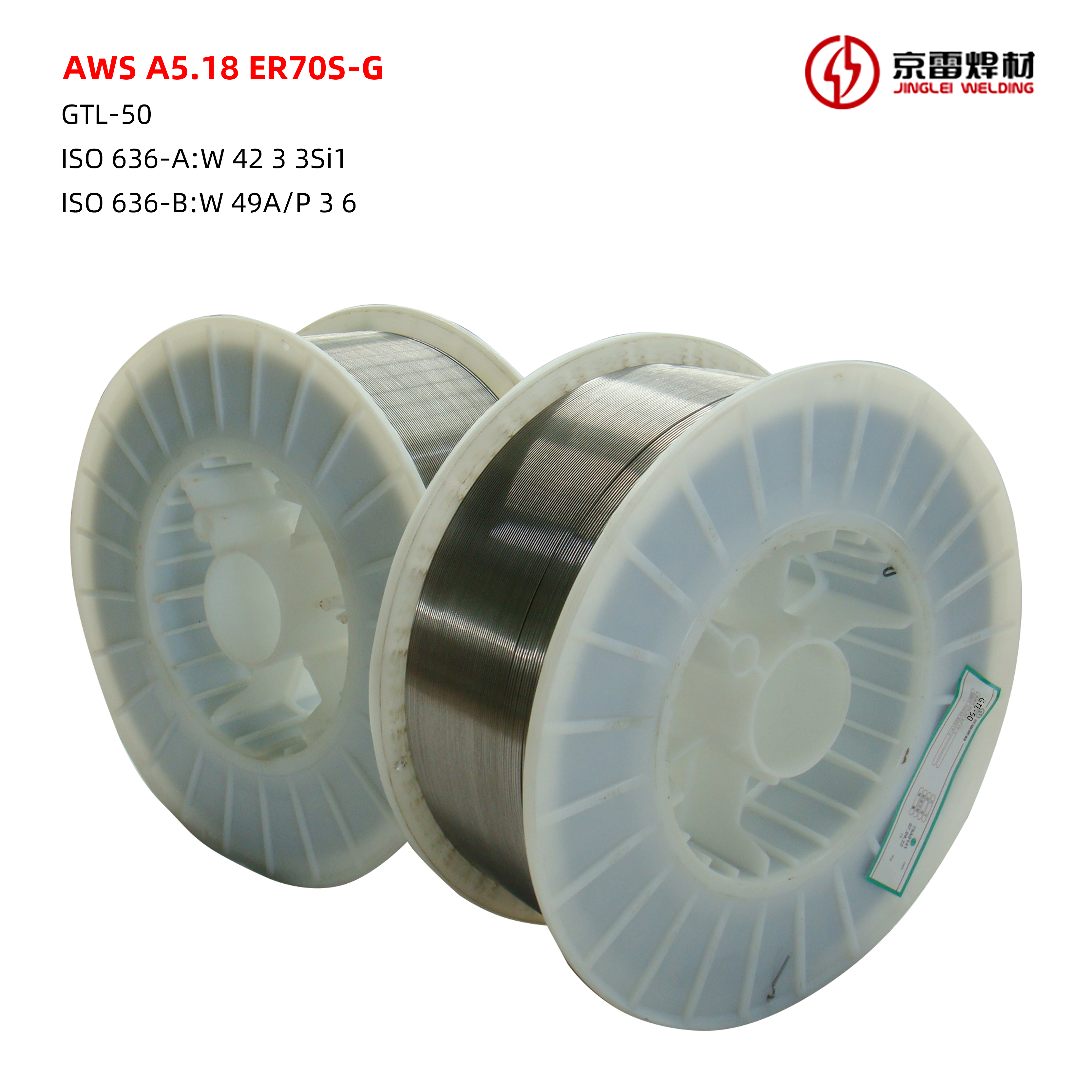

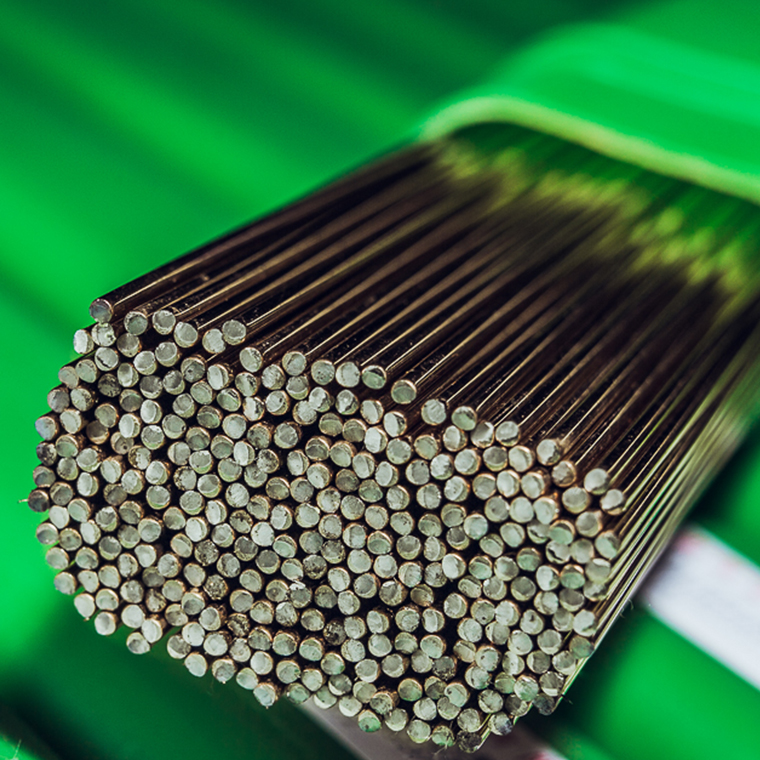

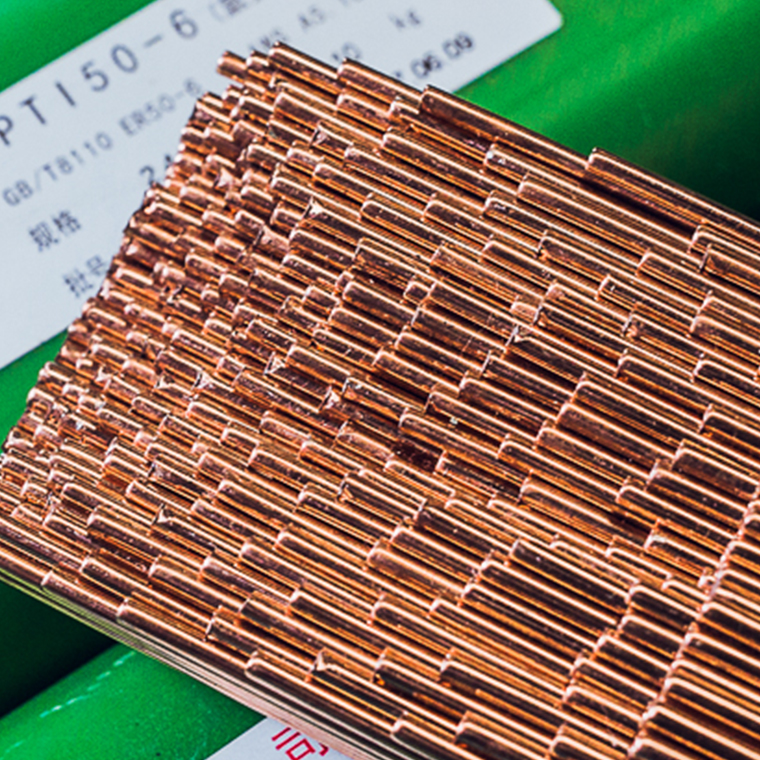

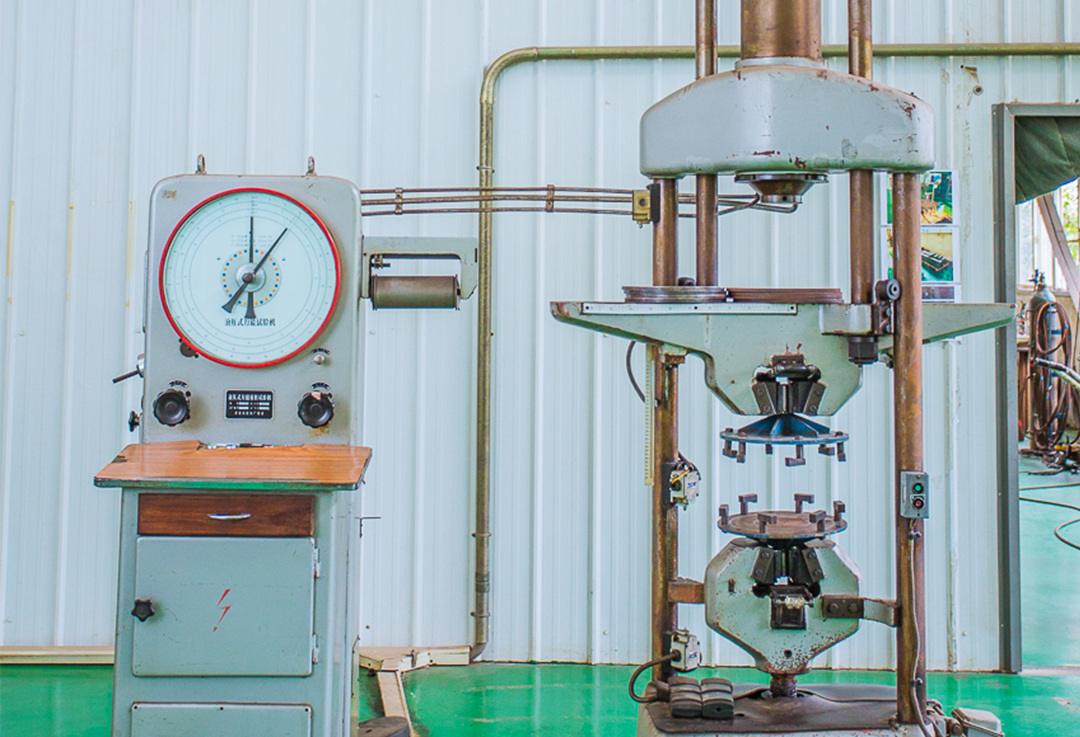

Hais txog peb

Factory fioor zaub

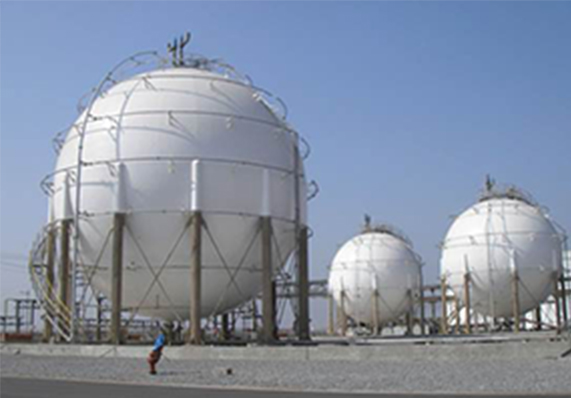

Cov ntaub ntawv thov

Shaanxi Pucheng -50 ℃ propane kheej kheej tank project

Kev kub siab rhaub ntawm Hangzhou Boiler Group Co. LTD

Lub Hoobkas tua

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | - | ≥1.00 Nws | ≥0.80 | ≥0.30 Nws | ≥0.50 | ≥0.20 | - | - | ≥0.10 |

| AWS RULES | - | ≥1.01 | ≥0.80 | ≥0.30 Nws | ≥0.50 | ≥0.20 | 0.030 Nws | 0.030 Nws | ≥0.10 |

| EXAMPLE VALUE | 0.070 ib | 1.55 ib | 0.32 ib | 0.031 ib | 0.82 ib | 0.31 Nws | 0.012 ib | 0.005 ib | 0.03 ib |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 490 ib | 590 ua | 620 * 1 | 27/-20 ib | 16 | ||||

| AWS RULES | 530 | 620 | 620 * 1 | - | 17 | ||||

| EXAMPLE VALUE | 585 ib | 670 ib | 620 * 1 | 85/-50 | 24 | ||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 350 | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 hli | |||||

| ELECTRICITY (Amp) | H/W | 80-110 : kuv | 110-130 : kuv | 130-180 Nws | 180-230 : kuv | ||||

| O/W | 50-80 | 90-120 : kuv | 130-160 : kuv | - | |||||

Sau koj cov lus ntawm no thiab xa tuaj rau peb