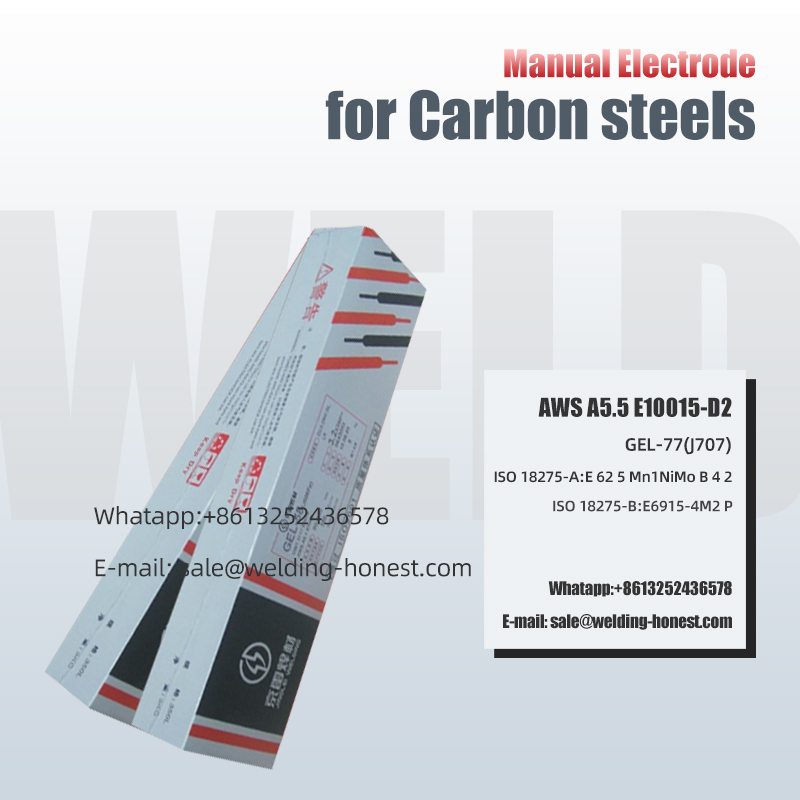

High Carbon steels Phau ntawv electrode E7018-1 weld fabrication khoom

Daim ntawv thov

Haum rau welding ntawm CARBON STEEL thiab qis hlau alloy, zoo li cov khoom siv zog ntawm Nuclear fais fab engineering, lub tsev, BRIDGE thiab lwm yam qauv, xws li Q345.

Tus qauv peb ntsib: GB/T5117 E5018-1, AWS A5.1 E7018-1 & A5.1M E4918-1, ISO2560-A:E 42 5 B 3 2 H5, ISO 2560-B: E4918-1 A.

Peculiarity

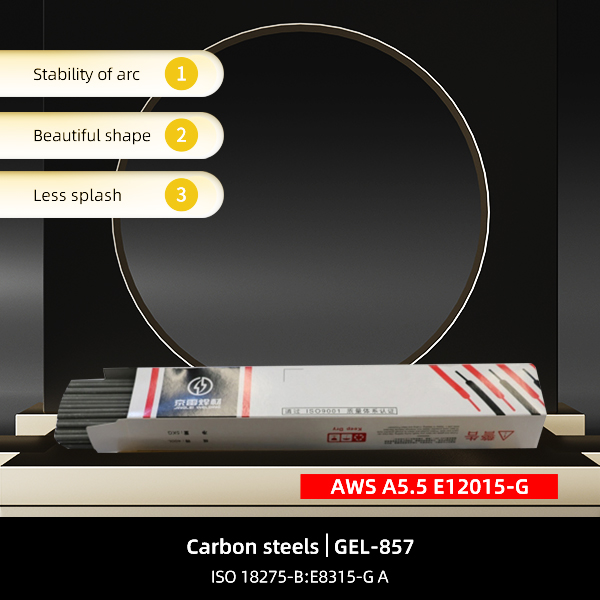

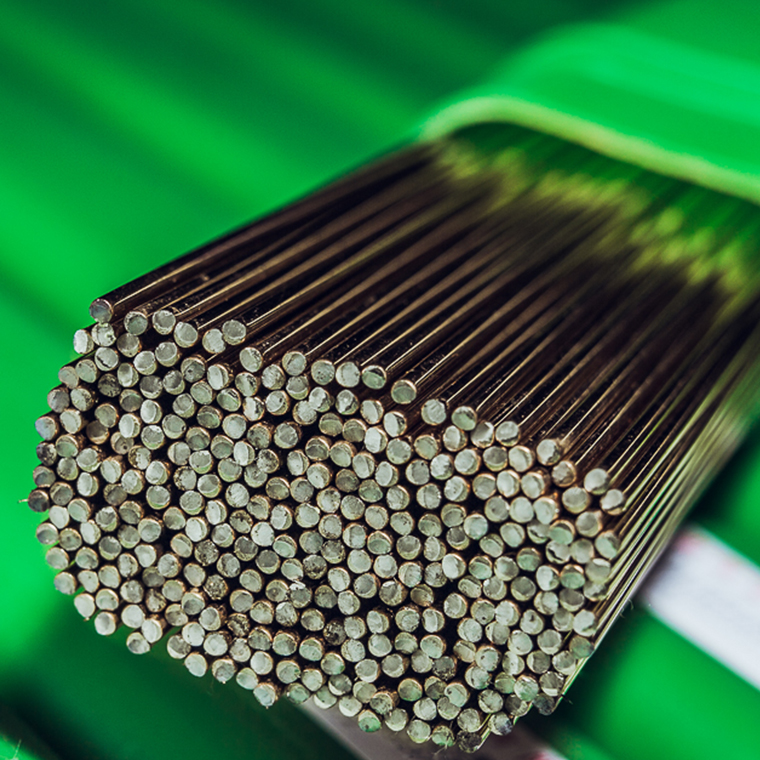

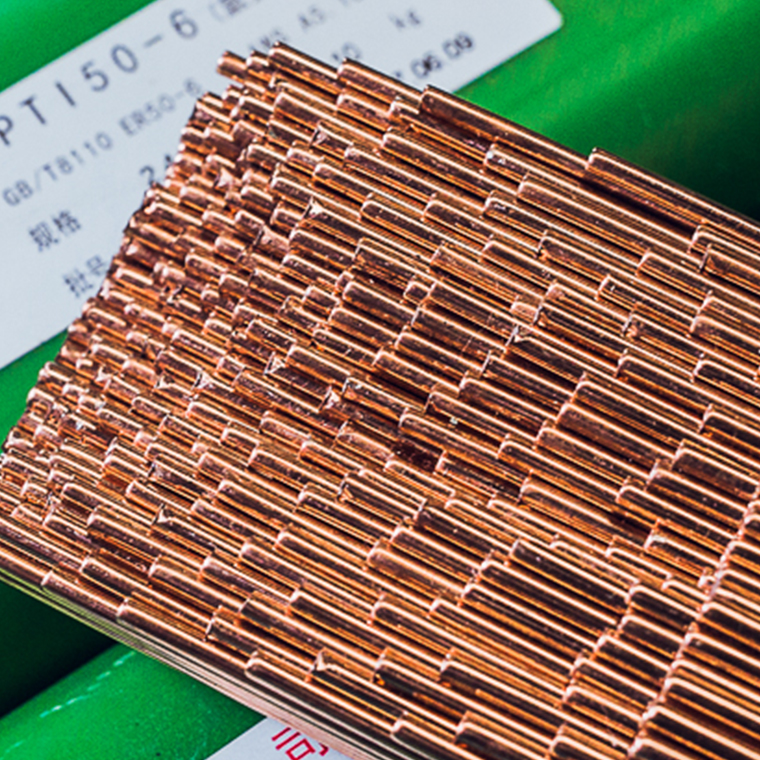

Hlau hmoov tsis tshua muaj hydrogen hom tes electrode, siab vuam efficiency, ruaj khov arc, zoo nkauj sib sau, corrugations.

Me ntsis txaws, yooj yim de-slagging, tshuaj zoo tawv nqaij tiv thaiv, zoo stomamal kuj.

Cov khoom siv ruaj khov, zoo plasticity thiab tsis tshua muaj kub cuam tshuam tenacity.

Qhia kom meej

Splash tsawg heev

Yooj yim slagging

Hais txog peb

Factory fioor zaub

Cov ntaub ntawv thov

Harbin Electric - Sanmen, Haiyang MSR

Qinghai Youjian Wunan Oilfield

Lub Hoobkas tua

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | 0.15 | 1.60 ib | 0.90 ib | 0.20 ib | 0.30 Nws | 0.30 Nws | 0.035 ib | 0.035 ib | 0.08 ib |

| AWS RULES | 0.15 | 1.60 ib | 0.75 ib | 0.20 ib | 0.30 Nws | 0.30 Nws | 0.035 ib | 0.035 ib | 0.08 ib |

| EXAMPLE VALUE | 0.065 ib | 1.40 Nws | 0.45 ib | 0.03 ib | 0.01 ib | 0.006 ib | 0.011 ib | 0.007 ib | 0.01 ib |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 400 | 490 ib | AW | 27/-45 ib | 20 | ||||

| AWS RULES | 400 | 490 ib | AW | 27/-45 ib | 22 | ||||

| EXAMPLE VALUE | 490 ib | 590 ua | AW | 128/-45 ib | 28 | ||||

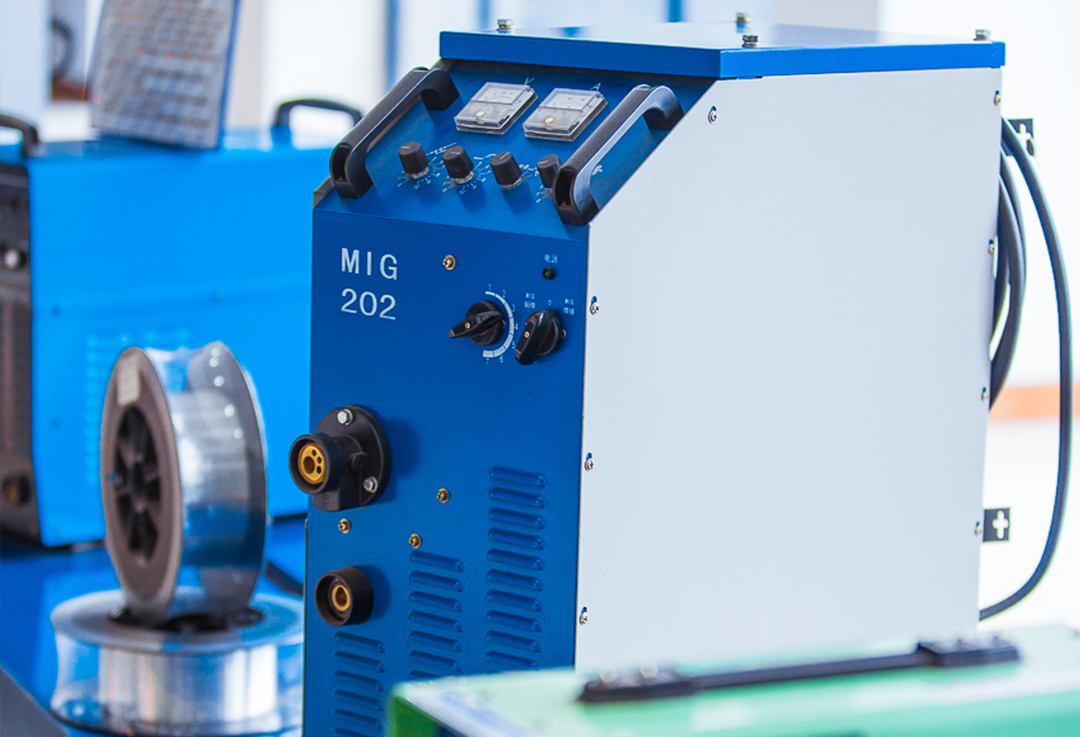

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 350 | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 hli | |||||

| ELECTRICITY (Amp) | H/W | 80-110 : kuv | 100-130 Nws | 130-180 Nws | 180-230 : kuv | ||||

| O/W | 50-80 | 90-120 : kuv | 130-160 : kuv | - | |||||

Sau koj cov lus ntawm no thiab xa tuaj rau peb