High Carbon steels Phau ntawv electrode E7015-G vuam kev ua

Daim ntawv thov

SUITable WELDING NTAWM CARBON STEEL THIAB LOW ALLOY STEEL, Zoo li lub zog sib xws ntawm boiler, pipeline, siab nkoj, dej hiav txwv engineering qauv vuam, xws li Q345, X60 pipeline steel, thiab lwm yam.

Tus qauv peb ntsib: GB/T5117 E5015-G AP, AWS A5.5 E7015-G & A5.5M E4915-G, ISO2560-A:E 42 4 Z0.5 Ni B 2 2, ISO 2560-B: E4915 G -AP.

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | - | - | - | - | - | - | - | - | - |

| AWS RULES | - | ≥1.00 Nws | ≥0.80 | ≥0.30 Nws | ≥0.50 | ≥0.20 | 0.030 Nws | 0.030 Nws | ≥0.10 |

| EXAMPLE VALUE | 0.075 ib | 1.45 Nws | 0.40 Nws | 0.03 ib | 0.50 ib | 0.004 ib | 0.014 ib | 0.006 ib | 0.01 ib |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 400 | 490 ib | 620 * 1 | - | 20 | ||||

| AWS RULES | 390 | 490 ib | 620 * 1 | - | 22 | ||||

| EXAMPLE VALUE | 450 | 550 | 620 * 1 | 114/- 50 | 27 | ||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 350 | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 hli | |||||

| ELECTRICITY (Amp) | H/W | 80-110 : kuv | 110-130 : kuv | 130-180 Nws | 180-230 : kuv | ||||

| O/W | 50-80 | 90-120 : kuv | 130-160 : kuv | - | |||||

Peculiarity

Tsawg hydrogen potassium electrode, ruaj khov arc, zoo nkauj tsim, exquisite, me ntsis txaws, yooj yim de-slagging, zoo tawv nqaij tiv taus, zoo porosity kuj.

Table mechanical zog, zoo plasticity, cuam tshuam toughness thiab tawg kuj.

Diffused hydrogen cov ntsiab lus yog tsawg.

Qhia kom meej

Zoo ripple

Splash tsawg heev

Hais txog peb

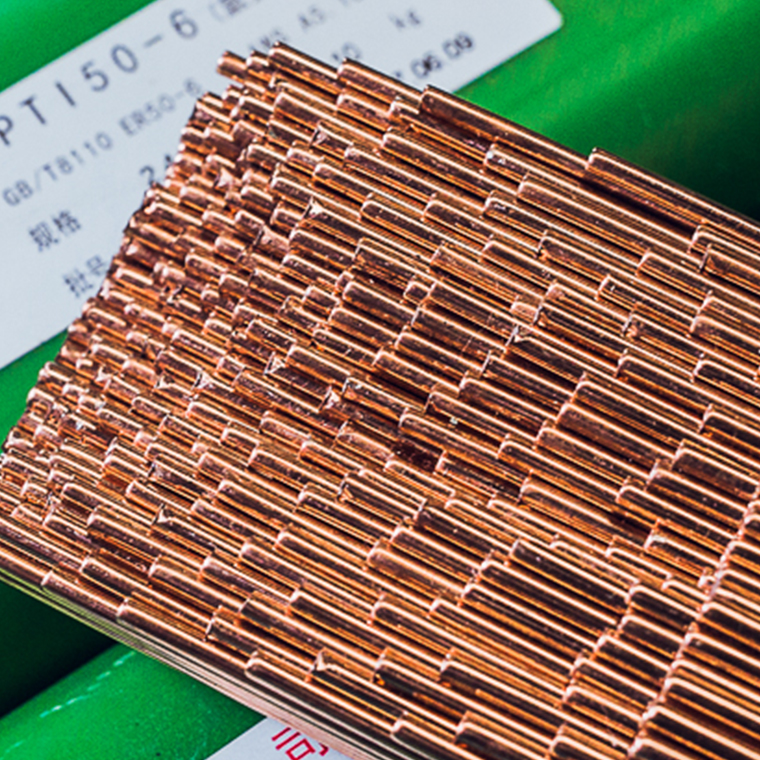

Factory fioor zaub

Cov ntaub ntawv thov

Xinjiang Kela 2 Central Treatment Plant Project

Vuam khoom rau Silencer

Lub Hoobkas tua

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | - | - | - | - | - | - | - | - | - |

| AWS RULES | - | ≥1.00 Nws | ≥0.80 | ≥0.30 Nws | ≥0.50 | ≥0.20 | 0.030 Nws | 0.030 Nws | ≥0.10 |

| EXAMPLE VALUE | 0.075 ib | 1.45 Nws | 0.40 Nws | 0.03 ib | 0.50 ib | 0.004 ib | 0.014 ib | 0.006 ib | 0.01 ib |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 400 | 490 ib | 620 * 1 | - | 20 | ||||

| AWS RULES | 390 | 490 ib | 620 * 1 | - | 22 | ||||

| EXAMPLE VALUE | 450 | 550 | 620 * 1 | 114/- 50 | 27 | ||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 350 | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 hli | |||||

| ELECTRICITY (Amp) | H/W | 80-110 : kuv | 110-130 : kuv | 130-180 Nws | 180-230 : kuv | ||||

| O/W | 50-80 | 90-120 : kuv | 130-160 : kuv | - | |||||

Sau koj cov lus ntawm no thiab xa tuaj rau peb