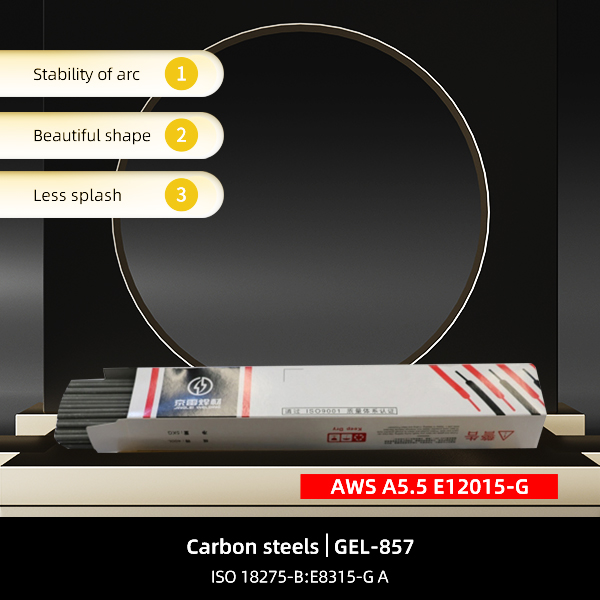

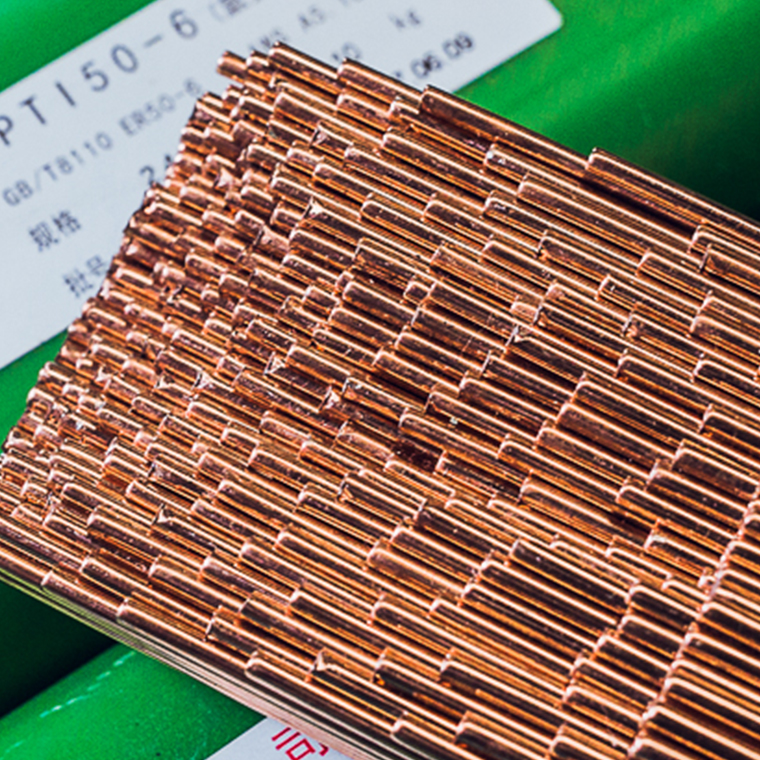

High Carbon steels Phau ntawv electrode E12015-G Soldering jointing

Daim ntawv thov

Haum rau qis alloy steel vuam ntawm tib lub zog qib hauv kev tsim kho tshuab. Nws yog tsuas yog siv los kho qhov tsis xws luag ntawm lub tsheb ciav hlau thiab lub tsheb ua los ntawm E - class steel.

Tus qauv peb tau ntsib: GB/T32533 E8315-G, AWS A5.5 E12015-G & A5.5M E8315-G, ISO18275-A:, ISO 18275-B: E8315-G A.

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | V |

| GB/T RULES | - | ≥1.00 Nws | ≥0.80 | ≥0.30 Nws | ≥0.50 | ≥0.20 | - | - | - | ≥0.10 |

| AWS RULES | - | ≥1.00 Nws | ≥0.80 | ≥0.30 Nws | ≥0.50 | ≥0.20 | 0.030 Nws | 0.030 Nws | ≥0.20 | ≥0.10 |

| EXAMPLE VALUE | 0.072 ib | 2.20 | 0.14 ib | 0.54 ib | 0.015 ib | 0.86 ib | 0.012 ib | 0.006 ib | 0.012 ib | 0.002 ib |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||

| GB/T RULES | 740 ib | 8 30 | AW | - | 12 | |||||

| AWS RULES | 740 ib | 8 30 | AW | - | 14 | |||||

| EXAMPLE VALUE | 820 | 880 ua | AW | 85 / Qhov kub thiab txias | 16 | |||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 350 | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 hli | ||||||

| ELECTRICITY (Amp) | H/W | 80-110 : kuv | 100-130 Nws | 130-180 Nws | 180-230 : kuv | |||||

| O/W | 50-80 | 90-120 : kuv | 130-160 : kuv | - | ||||||

Peculiarity

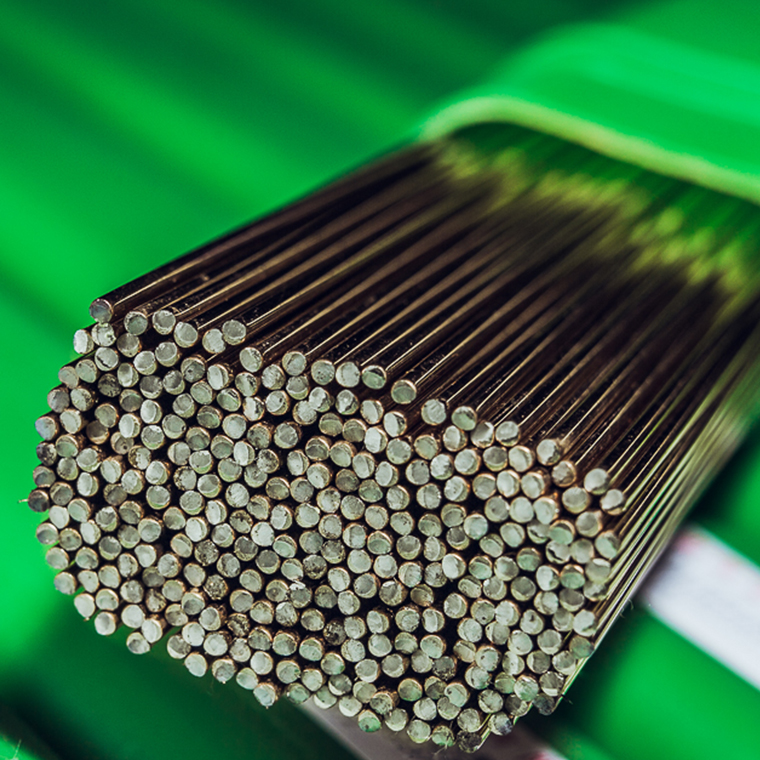

Tsawg sodium hydrogen electrode, ruaj khov arc, me me txaws.

Zoo sib sau, yooj yim desagging.

X-ray kev ua tau zoo yog qhov zoo, ruaj khov txhua yam khoom.

Qhia kom meej

Stability ntawm arc

Yooj yim slagging

Hais txog peb

Factory fioor zaub

Cov ntaub ntawv thov

300,000 tons bulk carrier

2.3 lab barrels SBM Fast4ward FPSO

Lub Hoobkas tua

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | V |

| GB/T RULES | - | ≥1.00 Nws | ≥0.80 | ≥0.30 Nws | ≥0.50 | ≥0.20 | - | - | - | ≥0.10 |

| AWS RULES | - | ≥1.00 Nws | ≥0.80 | ≥0.30 Nws | ≥0.50 | ≥0.20 | 0.030 Nws | 0.030 Nws | ≥0.20 | ≥0.10 |

| EXAMPLE VALUE | 0.072 ib | 2.20 | 0.14 ib | 0.54 ib | 0.015 ib | 0.86 ib | 0.012 ib | 0.006 ib | 0.012 ib | 0.002 ib |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||

| GB/T RULES | 740 ib | 8 30 | AW | - | 12 | |||||

| AWS RULES | 740 ib | 8 30 | AW | - | 14 | |||||

| EXAMPLE VALUE | 820 | 880 ua | AW | 85 / Qhov kub thiab txias | 16 | |||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 350 | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 hli | ||||||

| ELECTRICITY (Amp) | H/W | 80-110 : kuv | 100-130 Nws | 130-180 Nws | 180-230 : kuv | |||||

| O/W | 50-80 | 90-120 : kuv | 130-160 : kuv | - | ||||||

Sau koj cov lus ntawm no thiab xa tuaj rau peb