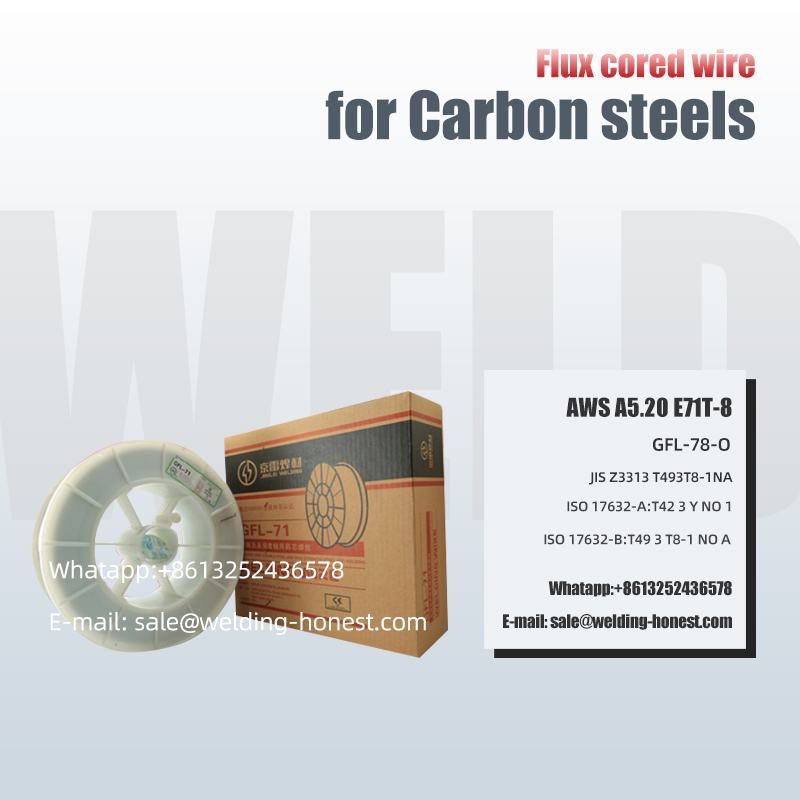

High Carbon steels Flux cored hlau E71T-11 weld fabrication accessories

Daim ntawv thov

Haum rau vuam lub teeb qauv ntawm nyias carbon hlau thiab galvanized hlau.

GB/T10045 T 49 Z T11 1 NA, AWS A5.20 E71T-11 & A5.20M E491T-11, ISO17632-A:T42 ZY NO 1, ISO 17632-T49 Z T11-1 NO A.

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | AI |

| GB/T RULES | 0.30 Nws | 2.00 Nws | 0.90 ib | 0.20 ib | 0.50 ib | 0.30 Nws | 0.030 Nws | 0.030 Nws | 2.00 Nws |

| AWS RULES | 0.30 Nws | 1.75 ib | 0.60 ib | 0.20 ib | 0.50 ib | 0.30 Nws | 0.03 ib | 0.03 ib | 1.80 ib |

| EXAMPLE VALUE | 0.160 Nws | 0.800 Nws | 0.30 Nws | 0.02 ib | 0.02 ib | 0.01 ib | 0.009 ib | 0.002 ib | 1.50 Nws |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||

| GB/T RULES | 390 | 490-670 : kuv | AW | - | 18 | |||||

| AWS RULES | 390 | 490-670 : kuv | AW | - | 20 | |||||

| EXAMPLE VALUE | 420 | 570 ib | AW | - | 25 | |||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 0.8 ua | 0.9 | 1 | 1.2 | 1.6 | |||||

| VOLT | 14-19 | 16-20 | 18-25 | 18-25 | 20-26 | |||||

| AMP | 40-140 : kuv | 60-160 : kuv | 80-200 | 140-260 : kuv | 180-300 Nws | |||||

| Ntev: MM | 10.00-15.00 Nws | 10.00-15.00 Nws | 10.00-15.00 Nws | 10.00-15.00 Nws | 10.00-15.00 Nws | |||||

Peculiarity

Kev tiv thaiv tus kheej flux-cored hlau rau siab zog steel ntawm chav kawm 490Mpa.

Yooj yim rau nqa, thiab tuaj yeem nqa tag nrho txoj haujlwm ntawm ib qho dhau los thiab ntau qhov kev vuam.

Arc mos thiab ruaj khov, me me txaws.

Qhia kom meej

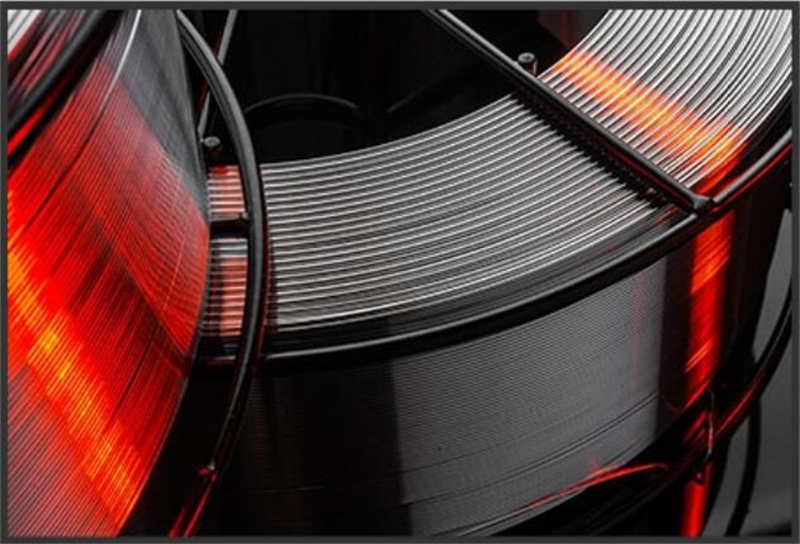

Lub arc yog mos thiab ruaj khov

Txau me me

Hais txog peb

Factory fioor zaub

Cov ntaub ntawv thov

Upper tub ntxhais SG

Vuam cov ntaub ntawv rau aluminium alloys

Lub Hoobkas tua

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | AI |

| GB/T RULES | 0.30 Nws | 2.00 Nws | 0.90 ib | 0.20 ib | 0.50 ib | 0.30 Nws | 0.030 Nws | 0.030 Nws | 2.00 Nws |

| AWS RULES | 0.30 Nws | 1.75 ib | 0.60 ib | 0.20 ib | 0.50 ib | 0.30 Nws | 0.03 ib | 0.03 ib | 1.80 ib |

| EXAMPLE VALUE | 0.160 Nws | 0.800 Nws | 0.30 Nws | 0.02 ib | 0.02 ib | 0.01 ib | 0.009 ib | 0.002 ib | 1.50 Nws |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||

| GB/T RULES | 390 | 490-670 : kuv | AW | - | 18 | |||||

| AWS RULES | 390 | 490-670 : kuv | AW | - | 20 | |||||

| EXAMPLE VALUE | 420 | 570 ib | AW | - | 25 | |||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 0.8 ua | 0.9 | 1 | 1.2 | 1.6 | |||||

| VOLT | 14-19 | 16-20 | 18-25 | 18-25 | 20-26 | |||||

| AMP | 40-140 : kuv | 60-160 : kuv | 80-200 | 140-260 : kuv | 180-300 Nws | |||||

| Ntev: MM | 10.00-15.00 Nws | 10.00-15.00 Nws | 10.00-15.00 Nws | 10.00-15.00 Nws | 10.00-15.00 Nws | |||||

Sau koj cov lus ntawm no thiab xa tuaj rau peb