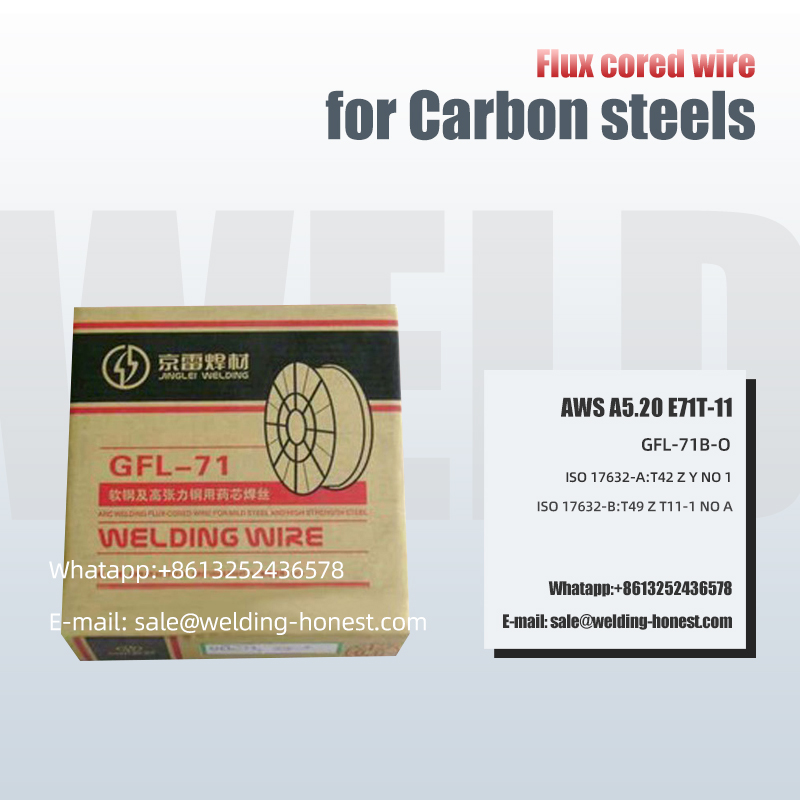

High Carbon steels Flux cored hlau E71T-11 Soldering jointing

Haum rau vuam lub teeb qauv ntawm nyias carbon hlau thiab galvanized hlau.

GB/T10045 T 49 Z T11 1 NA, AWS A5.20 E71T-11 & A5.20M E491T-11, ISO17632-A:T42 ZY NO 1, ISO 17632-T49 Z T11-1 NO A.

Dab tsi yog cov

yam ntxwv?

●Kev tiv thaiv tus kheej flux-cored hlau rau siab zog steel ntawm chav kawm 490Mpa.

●Yooj yim rau nqa, thiab tuaj yeem nqa tag nrho txoj haujlwm ntawm ib qho dhau los thiab ntau qhov kev vuam.

●Arc mos thiab ruaj khov.

●Txau me me.

Khoom Parameter

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | AI |

| GB/T RULES | 0.30 Nws | 2.00 Nws | 0.90 ib | 0.20 ib | 0.50 ib | 0.30 Nws | 0.030 Nws | 0.030 Nws | 2.00 Nws |

| AWS RULES | 0.30 Nws | 1.75 ib | 0.60 ib | 0.20 ib | 0.50 ib | 0.30 Nws | 0.03 ib | 0.03 ib | 1.80 ib |

| EXAMPLE VALUE | 0.160 Nws | 0.800 Nws | 0.30 Nws | 0.02 ib | 0.02 ib | 0.01 ib | 0.009 ib | 0.002 ib | 1.50 Nws |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||

| GB/T RULES | 390 | 490-670 : kuv | AW | - | 18 | |||||

| AWS RULES | 390 | 490-670 : kuv | AW | - | 20 | |||||

| EXAMPLE VALUE | 420 | 570 ib | AW | - | 25 | |||||

YUAV UA LI CAS YUAV TSUM PARAMETERS :

| DIAMETERS SPECIFICATIONS (mm) | 0.8 ua | 0.9 | 1 | 1.2 | 1.6 | |||||

| VOLT | 14-19 | 16-20 | 18-25 | 18-25 | 20-26 | |||||

| AMP | 40-140 : kuv | 60-160 : kuv | 80-200 | 140-260 : kuv | 180-300 Nws | |||||

| Ntev: MM | 10.00-15.00 Nws | 10.00-15.00 Nws | 10.00-15.00 Nws | 10.00-15.00 Nws | 10.00-15.00 Nws | |||||

Saib ntawm txoj kev

peb thauj

●Tsav tsheb thauj mus los

●Kev xa khoom

Saib

peb wareno

Cov phiaj xwm

peb koom nrog

●3,000-meter deepwater semi-submersible drilling platform "Haiyang Shiyou 981"

●Ib tug hydrogenation reactor nyob rau hauv Suav teb

Peb cov khoom

mus rau lub ntiaj teb no

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | AI |

| GB/T RULES | 0.30 Nws | 2.00 Nws | 0.90 ib | 0.20 ib | 0.50 ib | 0.30 Nws | 0.030 Nws | 0.030 Nws | 2.00 Nws |

| AWS RULES | 0.30 Nws | 1.75 ib | 0.60 ib | 0.20 ib | 0.50 ib | 0.30 Nws | 0.03 ib | 0.03 ib | 1.80 ib |

| EXAMPLE VALUE | 0.160 Nws | 0.800 Nws | 0.30 Nws | 0.02 ib | 0.02 ib | 0.01 ib | 0.009 ib | 0.002 ib | 1.50 Nws |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||

| GB/T RULES | 390 | 490-670 : kuv | AW | - | 18 | |||||

| AWS RULES | 390 | 490-670 : kuv | AW | - | 20 | |||||

| EXAMPLE VALUE | 420 | 570 ib | AW | - | 25 | |||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 0.8 ua | 0.9 | 1 | 1.2 | 1.6 | |||||

| VOLT | 14-19 | 16-20 | 18-25 | 18-25 | 20-26 | |||||

| AMP | 40-140 : kuv | 60-160 : kuv | 80-200 | 140-260 : kuv | 180-300 Nws | |||||

| Ntev: MM | 10.00-15.00 Nws | 10.00-15.00 Nws | 10.00-15.00 Nws | 10.00-15.00 Nws | 10.00-15.00 Nws | |||||

Sau koj cov lus ntawm no thiab xa tuaj rau peb