Hard-facing SAW vuam hlau thiab vuam flux weld fabrication khoom

Daim ntawv thov & Standard

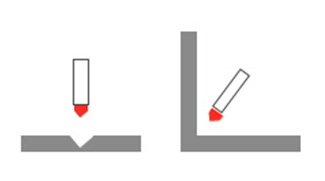

Qhov nyuaj saum npoo WEAR-resistant tes electrode yog tsuas yog tsim nyog rau qhov tsis tshua muaj kev cuam tshuam, khaus khaus qhov chaw, xws li kev tsim vaj tsev siv tshuab ua kom rov tsim dua tshiab, tshwj xeeb tshaj yog dredging machinery, thoob, xuab zeb suction twj. Surfacing yog ib txoj kev vuam nyob rau hauv qhov chaw los yog ntug ntawm cov hlau qhov chaw yog fused nrog ib txheej ntawm hnav tsis kam, corrosion kuj, kub tsis kam thiab lwm yam ntxwv ntawm cov ntaub ntawv hlau. Txhawm rau kho thiab txhim kho kev pabcuam lub neej ntawm cov khoom, siv cov khoom siv raw, txhim kho cov khoom lag luam, kev tswj tus nqi muaj txiaj ntsig kev lag luam. Tus txheej txheem ntawm surfacing yog heev complex. Nws yog ib qho tsim nyog yuav tau txais cov vuam hlau tsim nyog raws li cov cai sib txawv. Cov txheej txheem surfacing sib txawv yuav tsum tau siv rau qhov sib txawv ntawm cov hlau thiab cov khoom siv hluav taws xob kom tau txais cov txiaj ntsig zoo ntawm qhov chaw.

Nta

Qhov no yog qhov tsawg sodium hydrogen txheej hom surfacing electrode, siab hardness, tsis xav tau kev kho cua sov, tsis tuaj yeem txiav txuas ntxiv, hnav tsis kam. Hnav - resistant txheej txheem kev ua haujlwm kom raug tuaj yeem ua kom tag nrho cov tawv nqaij tuaj yeem yaj mus rau hauv lub pas dej molten los ntawm arc thaum lub sij hawm fusion vuam. Thiab weld core, substrate nto hlau sai melting los tsim ib tug tshiab hnav-resistant alloy. Nyob rau tib lub sijhawm, kev siv zog yuav tsum tau ua los txhim kho cov ntsiab lus carbon ntawm cov electrode ntawm qhov chaw ua haujlwm kom ntseeg tau tias cov txheej txheem vuam tau zoo heev los tiv thaiv. Txhawb kev tsim ntawm ntau yam carbides, ua kom nws hnav tsis kam. Rau cov khoom uas muaj kev cuam tshuam thiab abrasive hnav tib lub sijhawm hauv kev ua haujlwm, xws li rauj lub taub hau ntawm lub crusher, hauv ob sab phlu, tawb qws, thiab lwm yam. Cov txheej txheem vuam saum toj no yog deb ntawm qhov ua tau raws li qhov yuav tsum tau ua ntawm nws cov kev ua haujlwm, thiab yuav tsum tau txais ib txoj haujlwm sib txawv kiag li.

Tuam txhab & Hoobkas

Cov khoom muaj pes tsawg leeg thiab cov khoom siv kho tshuab kev taw qhia

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | P | S |

| GB/T RULES | 0.50-0.80 Nws | 0.50-1.50 Nws | 1.00 Nws | 4.00-8.00 Nws | 0.035 ib | 0.035 ib |

| AWS RULES | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.64 ib | 1.35 Nws | 0.94 ib | 7 | 0.027 ib | 0.007 ib |

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 3.2 * 350 | 4.0 * 350 | 5.0 * 350 | |||||

| ELECTRICITY (Amp) | 80-120 : kuv | 120-160 : kuv | 160-210 : kuv | |||||

TSEEM CEEB

Daim ntawv pov thawj

Cov khoom muaj pes tsawg leeg thiab cov khoom siv kho tshuab kev taw qhia

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | P | S |

| GB/T RULES | 0.50-0.80 Nws | 0.50-1.50 Nws | 1.00 Nws | 4.00-8.00 Nws | 0.035 ib | 0.035 ib |

| AWS RULES | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.64 ib | 1.35 Nws | 0.94 ib | 7 | 0.027 ib | 0.007 ib |

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 3.2 * 350 | 4.0 * 350 | 5.0 * 350 | |||||

| ELECTRICITY (Amp) | 80-120 : kuv | 120-160 : kuv | 160-210 : kuv | |||||