Hard-facing Phau ntawv electrode weld fabrication khoom

Daim ntawv thov & Standard

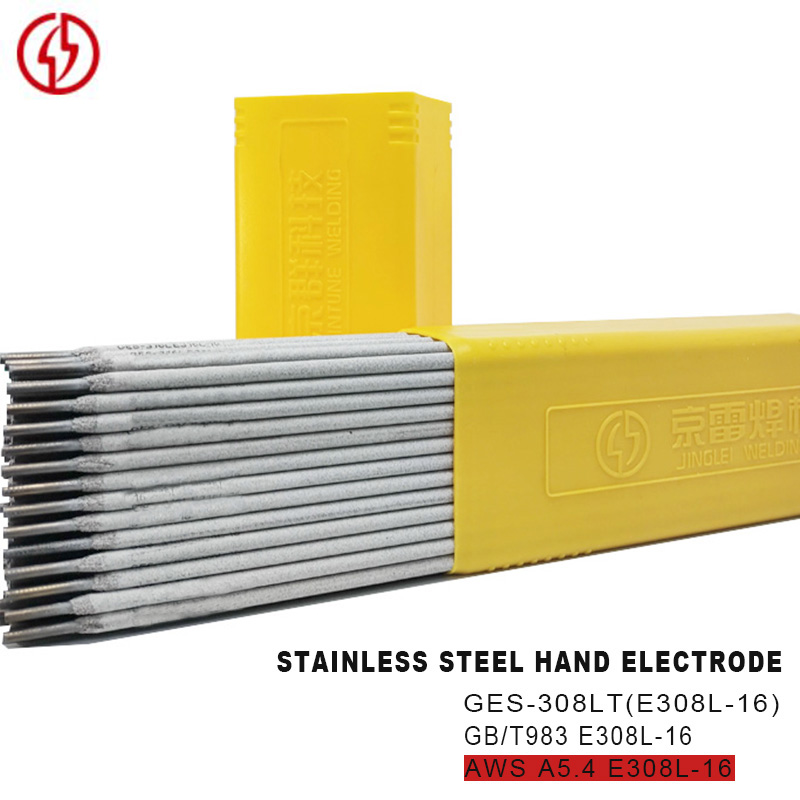

GEH-547 hardface wear-resisting tes electrode yog tsuas yog siv rau surfacing thiab kho qhov hnav ntawm cov khoom siv tshuaj thiab ntau yam khoom siv tshuab. Xws li slag crusher qhov tsis zoo (xws li crusher rauj, rauj phaj, txee phaj), cement kiln unloading device (tray, spire, grate), cib tshuab reamer, mixer hniav, dredging tshuab hniav, fais fab nroj tsuag kiv cua, steel zeb moj tej tawg. rauv chute hauv ob sab phlu, cov menyuam, cone tawg, charcoal tshuab thiab lwm yam. Cov nyhuv surfacing yog hais txog hardness, hnav tsis kam thiab kub tsis kam ntawm vuam txheej, thiab nws cov kev ua tau zoo muaj feem xyuam rau cov hauv qab no:

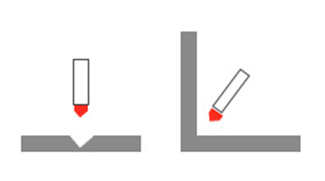

1. Vuam tam sim no loj, arc ntev. Tam sim no loj, ntev arc, alloying ntsiab yooj yim rau hlawv, txwv tsis pub, haum alloying ntsiab hloov. 2. Preheating kub thiab txias txias tej yam kev mob txiav txim qhov zoo ntawm cov surfacing txheej. 3. Cov txheej txheem kev kho cua sov sib txawv tuaj yeem siv kom tau qhov sib txawv hardness ntawm qee qhov saum npoo hlau.

Nta

GEH-547 yog ib qho tsis tshua muaj sodium hydrogen hom chromium-nickel taub qab vuam electrode, kev ua haujlwm zoo, tsis tshua muaj txaws, yooj yim rau slag, zoo nkauj zoo nkauj, yooj yim rau kev ua haujlwm; Lub zog ntawm silicon txhim khu lub hardness, abrasion tsis kam, corrosion kuj thiab oxidation tsis kam ntawm cov hlau surfacing. Qhov teeb meem feem ntau ntsib nyob rau saum npoo yog tawg. Cov txheej txheem tseem ceeb los tiv thaiv kev tawg yog raws li hauv qab no: 1. Preheat ua ntej vuam, tswj qhov kub ntawm cov khaubncaws sab nraud povtseg, qeeb txias tom qab vuam; 2. 2. Kev kho cua sov kom tshem tawm kev ntxhov siab tom qab vuam. 3, zam ntau txheej txheej nto tawg, siv tsawg hydrogen hom surfacing electrode. 4. Ua ntej vuam, nws yuav tsum tau qhuav ntawm 300-350 ℃ rau 1 teev; Yuav tsum tau tshem tawm cov khoom siv ntawm lub hauv paus saum npoo av noo, xeb stains, roj, thiab lwm yam. Kuj yuav tsum tau them sai sai rau txoj kev ntawm arc thiab arc.

Tuam txhab & Hoobkas

Cov khoom muaj pes tsawg leeg thiab cov khoom siv kho tshuab kev taw qhia

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | P | S |

| GB/T RULES | 0.18 | 0.60-2.00 Nws | 4.80-6.40 Nws | 15.00-18.00 Nws | 7.00-9.00 Nws | 0.04 ib | 0.030 Nws |

| AWS RULES | - | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.05 Nws | 1.26 | 5.34 ib | 16.8 ib | 7.78 ib | 0.028 ib | 0.006 ib |

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 3.2 * 350 | 4.0 * 350 | 5.0 * 350 | |||||

| ELECTRICITY (Amp) | 80-120 : kuv | 120-160 : kuv | 160-210 : kuv | |||||

TSEEM CEEB

Daim ntawv pov thawj

Cov khoom muaj pes tsawg leeg thiab cov khoom siv kho tshuab kev taw qhia

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | P | S |

| GB/T RULES | 0.18 | 0.60-2.00 Nws | 4.80-6.40 Nws | 15.00-18.00 Nws | 7.00-9.00 Nws | 0.04 ib | 0.030 Nws |

| AWS RULES | - | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.05 Nws | 1.26 | 5.34 ib | 16.8 ib | 7.78 ib | 0.028 ib | 0.006 ib |

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 3.2 * 350 | 4.0 * 350 | 5.0 * 350 | |||||

| ELECTRICITY (Amp) | 80-120 : kuv | 120-160 : kuv | 160-210 : kuv | |||||