Hard-facing phau ntawv electrode weld fabrication accessories

Daim ntawv thov & Standard

GEH-547Mo yog txhais tes electrode sib raug rau GB / T984 ED CrNi-B-15, uas yog siv rau txhua yam ntawm surfacing vuam thiab hlau nto vuam. Nws yog tsuas yog siv rau surfacing ntawm high-pressure valve sealing nto nrog ua hauj lwm kub qis dua 600 ℃. Los ntawm surfacing tshwj xeeb alloy rau saum npoo ntawm substrate, nws tuaj yeem ua tau raws li qhov xav tau ntawm kev hnav tsis kam thiab corrosion kuj. Kev kub siab ua hauj lwm los yog kev sib xyaw ua ke ntawm kev ua haujlwm. Txawm hais tias txo cov nqi tsim khoom, txhim kho cov khoom siv los ntawm kev kho ntau yam, los yog kev tswj xyuas kev tsim kho thiab cov duab ntawm lub workpiece, yog txoj kev yooj yim tshaj plaws thiab kev lag luam. Lub npe hu ua tawv tawv siv tshuab feem ntau hu ua hlau nto surfacing, txau lossis kho.

Nta

GEH-547Mo yog ib qho tsis tshua muaj sodium hydrogen coated high chromium nickel valve surfacing electrode, siv DC thim rov qab txuas. Cov hlau surfacing muaj zog los ntawm Si, Mo, W, V, Nb thiab lwm yam khoom kom tau txais cov qauv autonitic nrog ib qho me me ntawm ferrite, uas muaj qhov kub thiab txias tsis kam thiab yaig tsis kam, kub hardness, zoo thermal stability thiab thermal. qaug zog kuj. Lub aging hardening nyhuv ntawm hlau surfacing yog zoo kawg li. Nrog rau lub sij hawm laus zuj zus, lub hardness thiab abrasion kuj yog ntxiv txhim kho. Nws yog tsim rau surfacing lub sealing nto ntawm lub siab siab valve nrog ua hauj lwm kub hauv qab no 600 ℃, txhua yam valve plhaub, valve rooj, rooj vag phaj, lub ntsiab valve lub taub hau, kev ruaj ntseg qhov rooj thiab valve disc, thiab lwm yam.

Tuam txhab & Hoobkas

Cov khoom muaj pes tsawg leeg thiab cov khoom siv kho tshuab kev taw qhia

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | Nb | P | S |

| GB/T RULES | 0.18 | 0.60-5.00 Nws | 3.80-6.50 Nws | 14.00-21.00 Nws | 6.50-12.00 Nws | 3.50-7.00 Nws | 0.50-1.20 Nws | 0.04 ib | 0.03 ib |

| AWS RULES | - | - | - | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.05 Nws | 1.26 | 5.34 ib | 16.1 | 8.1 | 3.8 | 0.61 ib | 0.028 ib | 0.007 ib |

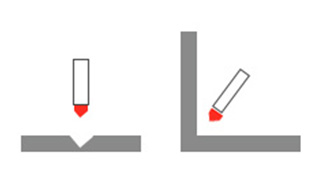

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 3.2 * 350 | 4.0 * 350 | 5.0 * 350 | |||||

| ELECTRICITY (Amp) | 80-120 : kuv | 120-160 : kuv | 160-210 : kuv | |||||

TSEEM CEEB

Daim ntawv pov thawj

Cov khoom muaj pes tsawg leeg thiab cov khoom siv kho tshuab kev taw qhia

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | Nb | P | S |

| GB/T RULES | 0.18 | 0.60-5.00 Nws | 3.80-6.50 Nws | 14.00-21.00 Nws | 6.50-12.00 Nws | 3.50-7.00 Nws | 0.50-1.20 Nws | 0.04 ib | 0.03 ib |

| AWS RULES | - | - | - | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.05 Nws | 1.26 | 5.34 ib | 16.1 | 8.1 | 3.8 | 0.61 ib | 0.028 ib | 0.007 ib |

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 3.2 * 350 | 4.0 * 350 | 5.0 * 350 | |||||

| ELECTRICITY (Amp) | 80-120 : kuv | 120-160 : kuv | 160-210 : kuv | |||||