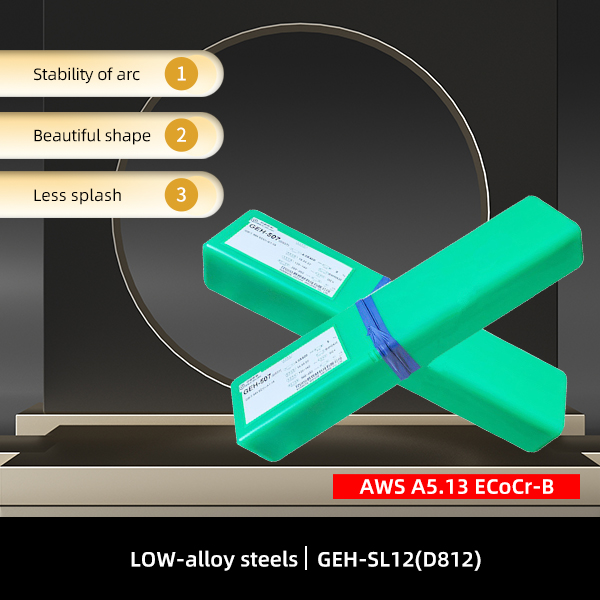

Hard-facing Flux cored hlau weld fabrication accessories

Daim ntawv thov & Standard

Yam khoom naj npawb GEH-507Mo no tawv tawv hnav-resistant tes electrode feem ntau yog siv rau hauv cov hlau hnav thiab dej vapor, qaug zog acid, cavitation thiab lwm yam, xws li valve sealing nto (qhov chaw ua hauj lwm hauv qab 550 ℃), ncej, mixer pulp, ntsia hlau conveyor hniav surfacing. Yog tias siv nrog D577 electrode, nws tuaj yeem tau txais kev puas tsuaj zoo. Thiab cov txheej txheem surfacing yog qhov yooj yim, tsis muaj preheating ua ntej vuam, tsis muaj kev kho cua sov tom qab vuam, siv DC rov qab txuas.

Nta

GEH-507Mo yog ib qho tsis tshua muaj sodium hydrogen hom siab chromium steel hardfacing sawb, kev ua haujlwm zoo, tsis tshua muaj txaws, yooj yim slag tshem tawm, zoo nkauj zoo nkauj, yooj yim rau kev ua haujlwm; Cov txheej saum npoo muaj cov yam ntxwv ntawm huab cua quenching, siab nruab nrab-kub hardness, zoo thermal stability thiab corrosion kuj. Hom electrode no yuav tsum tau them sai sai rau ntau yam teeb meem ua ntej vuam, kom tsis txhob ua yuam kev tsis tsim nyog rau kev ua haujlwm vuam. Thawj qhov taw tes: nws yuav tsum tau qhuav ntawm 300-350 ℃ rau 1 teev ua ntej vuam. Qhov thib ob point: lub hauv paus khoom nto ya raws, xeb stains, roj yuav tsum tau muab tshem tawm tag nrho. Qhov thib peb taw tes: xyuam xim rau txoj kev ntawm arc thiab arc, arc tom qab lub arc rov qab hlawv, remelting arc point, arc mus sau lub arc qhov.

Tuam txhab & Hoobkas

Cov khoom muaj pes tsawg leeg thiab cov khoom siv kho tshuab kev taw qhia

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | W |

| GB/T RULES | 0.20 ib | - | - | 10.00-16.00 Nws | 6.00 Nws | 2.50 Nws | 2.000 |

| AWS RULES | - | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.1 | 0.35 Nws | 1.10 | 12.8 ib | 2 | 1.41 ib | 0.02 ib |

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 3.2 * 350 | 4.0 * 350 | 5.0 * 350 | |||||

| ELECTRICITY (Amp) | 80-120 : kuv | 120-160 : kuv | 160-210 : kuv | |||||

TSEEM CEEB

Daim ntawv pov thawj

Cov khoom muaj pes tsawg leeg thiab cov khoom siv kho tshuab kev taw qhia

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | W |

| GB/T RULES | 0.20 ib | - | - | 10.00-16.00 Nws | 6.00 Nws | 2.50 Nws | 2.000 |

| AWS RULES | - | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.1 | 0.35 Nws | 1.10 | 12.8 ib | 2 | 1.41 ib | 0.02 ib |

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 3.2 * 350 | 4.0 * 350 | 5.0 * 350 | |||||

| ELECTRICITY (Amp) | 80-120 : kuv | 120-160 : kuv | 160-210 : kuv | |||||