Hard-facing D507Mo phau ntawv electrode vuam accessories

Daim ntawv thov & Standard

1. Nws yog siv rau intermetallic hnav thiab vuam ntawm qhov chaw cuam tshuam los ntawm dej vapor, qaug zog acid, cavitation, thiab lwm yam, xws li valve sealing nto (hauv qab 510 ° C), ncej, tov khoom pulp, ntsia hlau conveyor ntawv, thiab lwm yam.

2. Tus qauv peb tau ntsib: GB/T984 EDCr-A2-15

Nta

1. Tsawg hydrogen sodium hom high chromium steel surfacing electrode, kev ua haujlwm zoo, tsis tshua muaj spatter, yooj yim slag tshem tawm, zoo nkauj tsim, yooj yim rau kev siv tshuab.

2. Cov txheej saum npoo muaj cov yam ntxwv ntawm huab cua quenching, siab nruab nrab kub hardness, zoo thermal stability thiab corrosion kuj.

Tuam txhab & Hoobkas

TSEEM CEEB

Daim ntawv pov thawj

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | W |

| GB/T RULES | 0.20 ib | - | - | 10.00-16.00 Nws | 6.00 Nws | 2.50 Nws | 2.00 Nws |

| AWS RULES | - | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.1 | 0.35 Nws | 1.1 | 12.8 ib | 2.00 Nws | 1.41 ib | 0.02 ib |

WELDING HARDNESS

EXAMPLE: HRC = 41

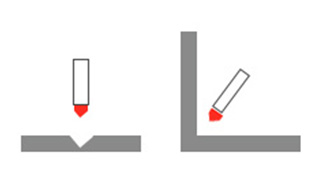

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 3.2 * 350 | 4.0 * 350 | 5.0 * 350 | ||||

| ELECTRICITY (Amp) | 80-120 : kuv | 120-160 : kuv | 160-210 : kuv |

Sau koj cov lus ntawm no thiab xa tuaj rau peb