Cobalt Alloys Phau Ntawv Electrode EDCoCr-B Vuam accessories

Daim ntawv thov

Yuav siv tau rau qhov kub thiab txias li qub, siab siab twj tso kua mis ncej tes tsho thiab lub tsho hauv ob sab phlu, tshuaj fiber ntau cov cuab yeej txiav ntug, sawtooth, ntsia hlau thawb pas nrig, thiab lwm yam.

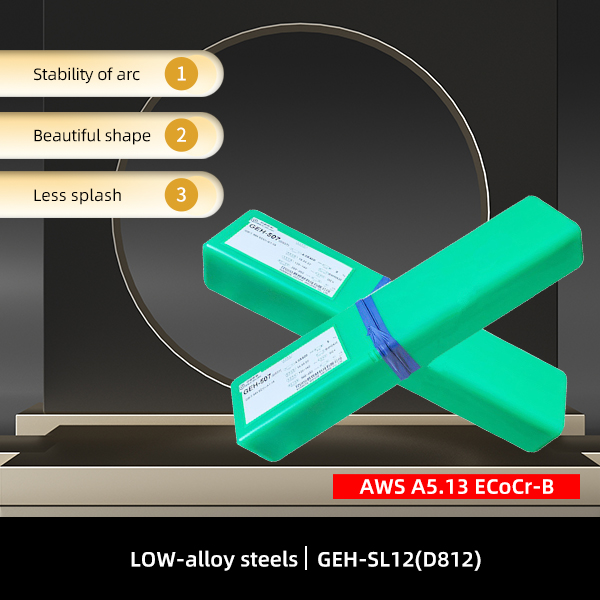

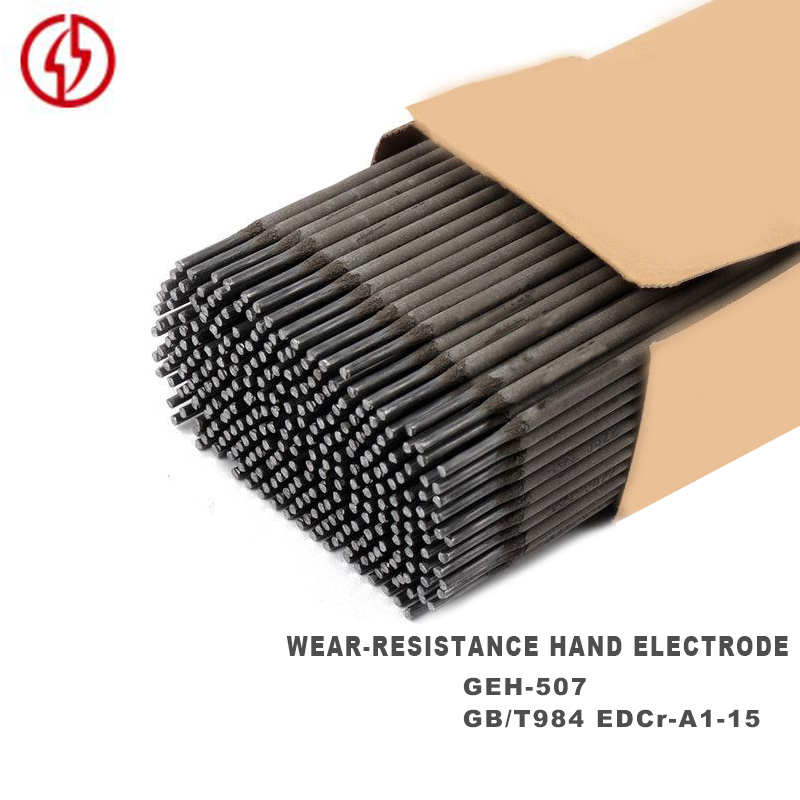

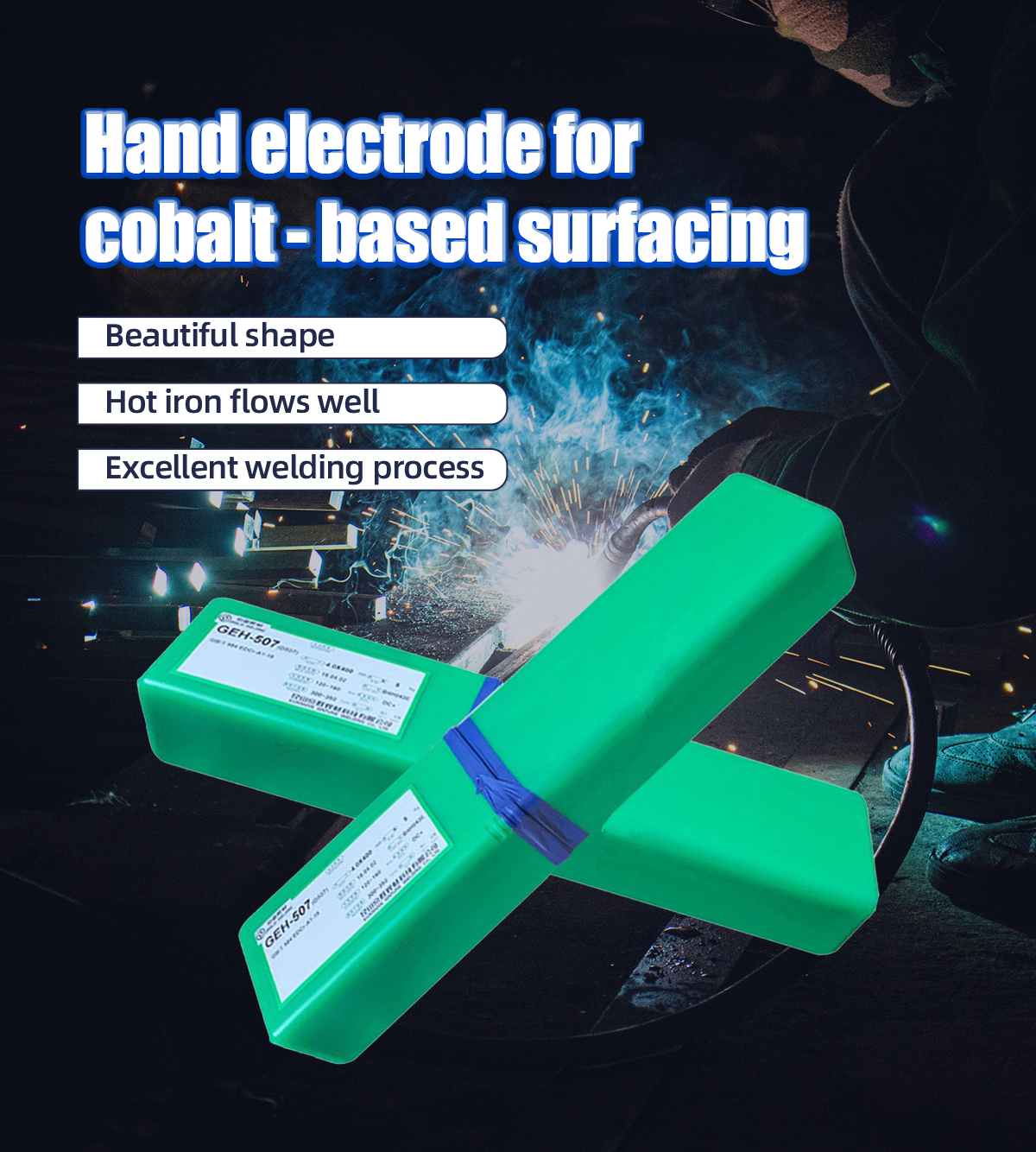

Peculiarity

Titanium-calcium coated cobalt-based surfacing electrode nrog cobalt-chromium-tungsten alloy raws li cov tub ntxhais hlau yuav tsum tau saws.

Siv DC rov qab txuas.

Surfacing hlau tuaj yeem tswj tau zoo hnav thiab corrosion kuj ntawm 650 ℃.

Qhia kom meej

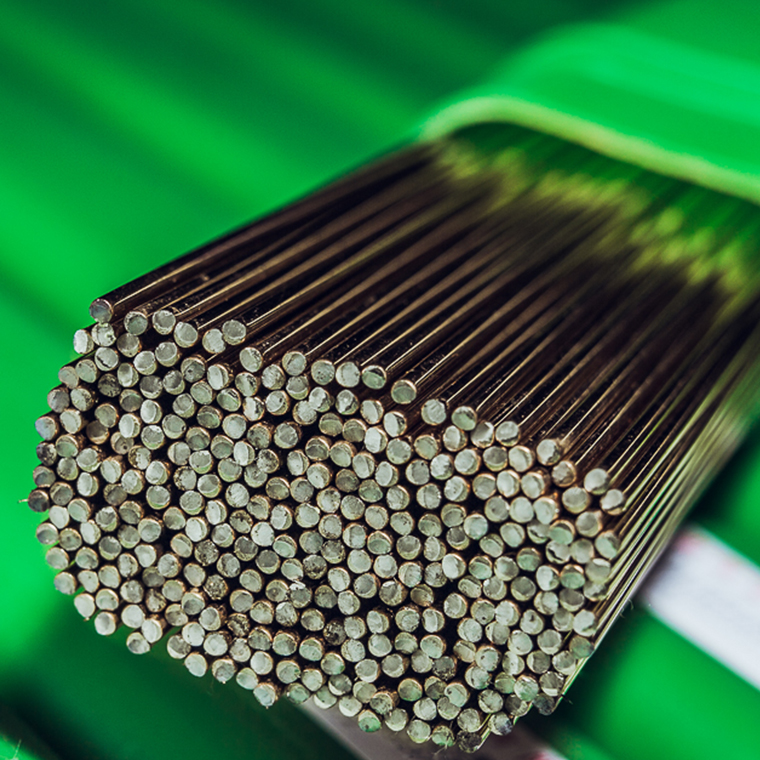

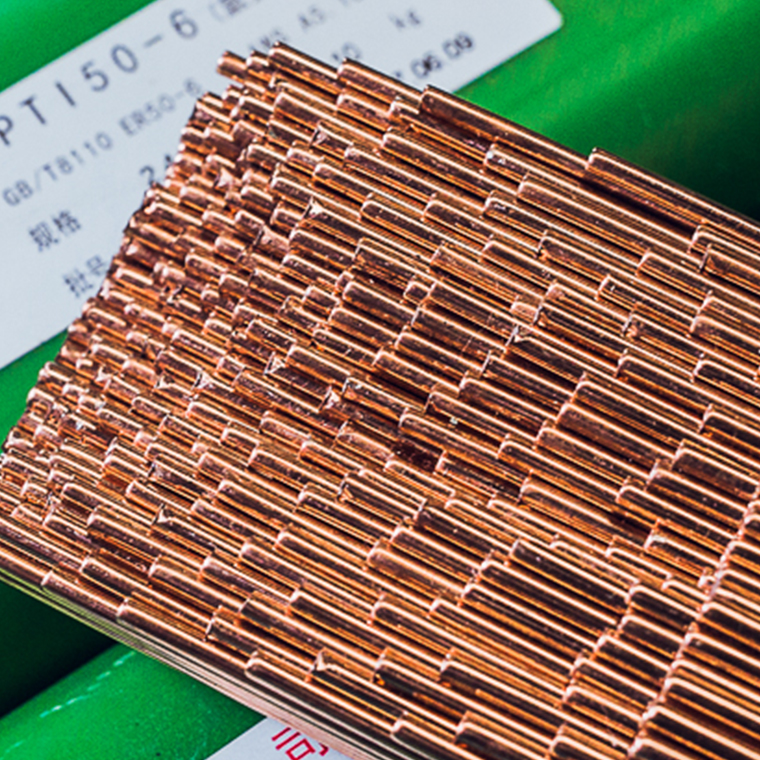

Cov duab zoo nkauj

Cov duab zoo nkauj

Hais txog peb

Factory fioor zaub

Cov ntaub ntawv thov

Sino-Russian Eastern Front

Hainan Huasheng phenol rov qab ntauwd

Lub Hoobkas tua

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | W | Co |

| GB/T RULES | 1.00-1.70 Nws | 2.00 Nws | 2.00 Nws | 25.00-32.00 Nws | - | - | 5 | 7.00-10.00 Nws | Margin |

| AWS RULES | 1.0-1.7 Nws | 2.00 Nws | 2.00 Nws | 25-32 : kuv | 3.00 Nws | 1.00 Nws | 5.00 Nws | 7.0-9.5 Nws | Margin |

| EXAMPLE VALUE | 1.15 | 1.31 ib | 1.12 | 30.5 ib | 2.4 | 0.1 | 3.500 Nws | 8.3 | Margin |

WELD PASS HARDNESS:

Piv txwv tus nqi HRC = 46

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 3.2 * 350 | 4.0 * 350 | 5.0 * 350 | ||||||||

| ELECTRICITY (Amp) | 120-160 : kuv | 140-190 : kuv | 150-210 : kuv | ||||||||

Sau koj cov lus ntawm no thiab xa tuaj rau peb