Hauv qab nqe Tyue TIG Submerge Arc MIG Vuam Hlau Em12

Peb lub koom haum ua raws li koj lub hauv paus ntsiab lus ntawm "Zoo tej zaum yuav yog lub neej ntawm koj lub koom haum, thiab lub koob npe nrov yuav yog tus ntsuj plig ntawm nws" rau hauv qab nqe Tyue TIG Submerge Arc MIG Vuam Hlau Em12, Peb zoo siab tos txais lub sijhawm los ua lag luam nrog koj thiab vam tias yuav txaus siab rau txuas ntxiv qhov tshwj xeeb ntawm peb cov khoom.

Peb lub koom haum ua raws li koj lub hauv paus ntsiab lus ntawm "Zoo yuav yog lub neej ntawm koj lub koom haum, thiab lub koob npe nrov yuav yog tus ntsuj plig ntawm nws" rauTuam Tshoj Vuam Hlau thiab Solder Hlau, Peb ua raws li cov neeg siv khoom 1st, zoo tshaj plaws 1st, kev txhim kho txuas ntxiv, kev sib nrig sib pab thiab yeej-yeej cov ntsiab lus. Thaum kev koom tes ua ke nrog cov neeg siv khoom, peb muab cov neeg yuav khoom nrog cov kev pabcuam zoo tshaj plaws. Tsim kom muaj kev sib raug zoo ntawm kev lag luam siv Zimbabwe tus neeg yuav khoom hauv kev lag luam, peb tau tsim tus kheej lub npe thiab lub koob npe nrov. Thaum lub sij hawm zoo tib yam, tag nrho lub siab txais tos cov tshiab thiab qub zeem muag rau peb lub tuam txhab mus rau thiab sib tham txog kev lag luam me.

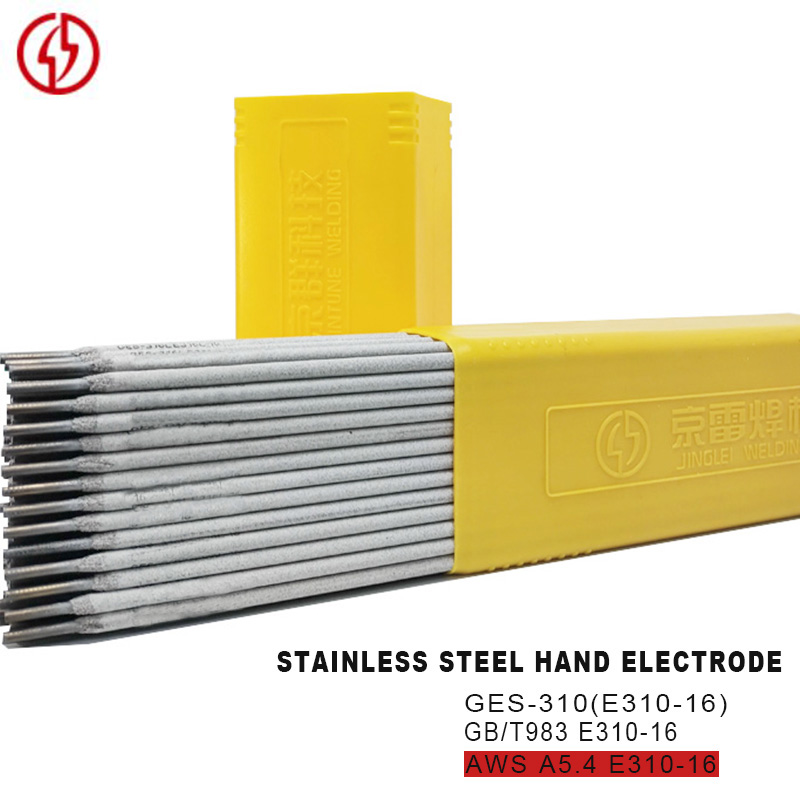

Daim ntawv thov & Standard

GEH-80 hardface hnav-tiv taus tes vuam electrode yog tsuas yog siv rau surfacing lossis kho qhov chaw ua haujlwm nyob rau hauv kev cuam tshuam cov khoom siv nrog abrasive hnav, xws li bulldozer hniav phaj, dredging thoob hniav, qhob tov khoom hniav, hydraulic machinery thiab mining machinery qhov chaw. Kev tiv thaiv kev nyab xeeb nyob rau hauv cov txheej txheem ntawm hnav-resistant electrode vuam:

Thaum lub vuam qhov chaw ntub dej, tus welder yuav tsum sawv ntsug ntawm lub rwb thaiv tsev qhuav los yog roj hmab ncoo, thiab cov neeg ua haujlwm koom tes yuav tsum hnav cov khau rwb thaiv tsev los yog sawv ntsug ntawm lub rwb thaiv tsev los yog roj hmab ncoo.

Thaum hnav-resistant electrode vuam preheating workpiece, yuav tsum muaj kev ntsuas rwb thaiv tsev xws li ntaub asbestos lossis baffle.

Thaum tshem cov welding slag, cov iav tiv thaiv los yog lub ntsej muag lub ntsej muag yuav tsum hnav, thiab lub taub hau yuav tsum zam cov kev taw qhia ntawm lub khob welding slag splashing los tiv thaiv cov hlau slag splashing neeg mob.

Nta

GEH-80 yog ib qho tsis tshua muaj sodium hydrogen kev sib txuas lus nruab nrab thiab qis alloy steel surfacing electrode, zoo heev technology; Nws yog feem ntau siv rau surfacing ntawm spare qhov chaw nyob rau hauv ib txwm kub thiab tsis-corrosive tej yam kev mob. Vim muaj cov ntsiab lus carbon siab thiab tsis muaj zog, nws yog qhov zoo tshaj plaws los siv alkaline structural steel electrode (xws li J507) ua lub hauv paus rau vuam.

Thaum siv arc cua gouging cag, cov iav tiv thaiv los yog lub ntsej muag lub ntsej muag yuav tsum tau hnav kom tiv thaiv kev raug mob los ntawm hlau slag splashing.

Thaum muaj ntau lub vuam vuam ua ke tib lub sijhawm, lub vuam platform lossis vuam yuav tsum tau muab tso rau hauv av, thiab lub teeb pov thawj yuav tsum tau teeb tsa.

Thaum TIV THAIV MACHINERY thiab cov khoom siv rau vuam, lub zog yuav tsum raug txiav tawm thiab cov cim kev nyab xeeb ntawm "kev kho thiab kev tsim kho, tsis muaj kev ua haujlwm" yuav tsum tau teeb tsa lossis cov neeg ua haujlwm tshwj xeeb yuav tsum muaj lub luag haujlwm saib xyuas.

Tuam txhab & Hoobkas

Cov khoom muaj pes tsawg leeg thiab cov khoom siv kho tshuab kev taw qhia

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | P | S |

| GB/T RULES | - | - | - | - | - | - |

| AWS RULES | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.45 ib | 0.72 ib | 1.93 ib | 8.3 | 0.027 ib | 0.006 ib |

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 3.2 * 350 | 4.0 * 350 | 5.0 * 350 | |||||

| ELECTRICITY (Amp) | 80-120 : kuv | 120-160 : kuv | 160-210 : kuv | |||||

TSEEM CEEB

Daim ntawv pov thawj

Peb lub koom haum ua raws li koj lub hauv paus ntsiab lus ntawm "Zoo tej zaum yuav yog lub neej ntawm koj lub koom haum, thiab lub koob npe nrov yuav yog tus ntsuj plig ntawm nws" rau hauv qab nqe Tyue TIG Submerge Arc MIG Vuam Hlau Em12, Peb zoo siab txais tos muaj lub sijhawm los ua lag luam nrog koj thiab vam tias yuav txaus siab rau txuas ntxiv qhov tshwj xeeb ntawm peb cov khoom.

Tus nqi hauv qabTuam Tshoj Vuam Hlau thiab Solder Hlau, Peb ua raws li cov neeg siv khoom 1st, zoo tshaj plaws 1st, kev txhim kho txuas ntxiv, kev sib nrig sib pab thiab yeej-yeej cov ntsiab lus. Thaum kev koom tes ua ke nrog cov neeg siv khoom, peb muab cov neeg yuav khoom nrog cov kev pabcuam zoo tshaj plaws. Tsim kom muaj kev sib raug zoo ntawm kev lag luam siv Zimbabwe tus neeg yuav khoom hauv kev lag luam, peb tau tsim tus kheej lub npe thiab lub koob npe nrov. Thaum lub sij hawm zoo tib yam, tag nrho lub siab txais tos cov tshiab thiab qub zeem muag rau peb lub tuam txhab mus rau thiab sib tham txog kev lag luam me.

Cov khoom muaj pes tsawg leeg thiab cov khoom siv kho tshuab kev taw qhia

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | P | S |

| GB/T RULES | - | - | - | - | - | - |

| AWS RULES | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.45 ib | 0.72 ib | 1.93 ib | 8.3 | 0.027 ib | 0.006 ib |

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 3.2 * 350 | 4.0 * 350 | 5.0 * 350 | |||||

| ELECTRICITY (Amp) | 80-120 : kuv | 120-160 : kuv | 160-210 : kuv | |||||