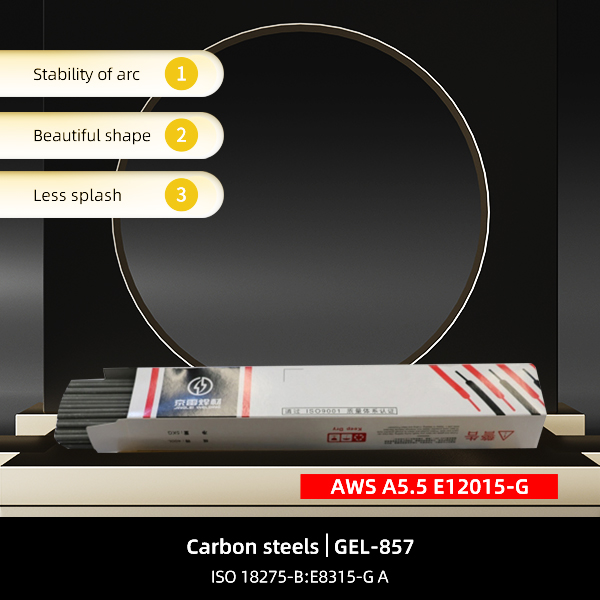

Qhov zoo tshaj plaws Muag Kub Muag Alloy Steel Vuam Electrodes E12015-G

mus rau boost, ua tej yam khoom zoo nyob rau hauv txoj kab nrog kev ua lag luam thiab buyer standard xav tau. Peb lub tuam txhab muaj cov txheej txheem kev ruaj ntseg zoo heev tshwm sim los tsim kom tau Zoo Tshaj Plaws Kub Muag Alloy Steel Vuam Electrodes E12015-G, Tam sim no, peb xav ua ntej kom muaj kev koom tes loj dua nrog cov neeg siv khoom txawv teb chaws raws li kev sib nrig sib zoo. Nco ntsoov xav tiv tauj peb kom paub meej ntxiv.

mus rau boost, ua tej yam khoom zoo nyob rau hauv txoj kab nrog kev ua lag luam thiab buyer standard xav tau. Peb lub tuam txhab muaj cov txheej txheem kev lees paub zoo heev tshwm sim los tsim rauTuam Tshoj Vuam Electrode thiab E12015-G, Raws li lub hauv paus ntsiab lus ntawm kev ua lag luam yog "ua lag luam-taw qhia, kev ntseeg zoo raws li txoj cai, yeej-yeej raws li lub hom phiaj", tuav ntawm "tus neeg siv khoom ua ntej, kev lees paub zoo, kev pabcuam ua ntej" raws li peb lub hom phiaj, mob siab rau muab qhov zoo tshaj plaws, tsim kev pabcuam zoo, peb yeej qhov kev qhuas thiab kev ntseeg siab hauv kev lag luam ntawm qhov chaw pib. Nyob rau hauv lub neej yav tom ntej, Peb yuav muab cov khoom zoo thiab cov kev pab zoo heev rov qab los rau peb cov neeg muas zaub, zoo siab txais tos cov lus qhia thiab tawm tswv yim los ntawm thoob plaws lub ntiaj teb no.

Haum rau qis alloy steel vuam ntawm tib lub zog qib hauv kev tsim kho tshuab. Nws yog tsuas yog siv los kho qhov tsis xws luag ntawm lub tsheb ciav hlau thiab lub tsheb ua los ntawm E - chav kawm hlau.

Tus qauv peb tau ntsib: GB/T32533 E8315-G, AWS A5.5 E12015-G & A5.5M E8315-G, ISO18275-A:, ISO 18275-B: E8315-G A.

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | V |

| GB/T RULES | - | ≥1.00 Nws | ≥0.80 | ≥0.30 Nws | ≥0.50 | ≥0.20 | - | - | - | ≥0.10 |

| AWS RULES | - | ≥1.00 Nws | ≥0.80 | ≥0.30 Nws | ≥0.50 | ≥0.20 | 0.030 Nws | 0.030 Nws | ≥0.20 | ≥0.10 |

| EXAMPLE VALUE | 0.072 ib | 2.20 | 0.14 ib | 0.54 ib | 0.015 ib | 0.86 ib | 0.012 ib | 0.006 ib | 0.012 ib | 0.002 ib |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||

| GB/T RULES | 740 ib | 8 30 | AW | - | 12 | |||||

| AWS RULES | 740 ib | 8 30 | AW | - | 14 | |||||

| EXAMPLE VALUE | 820 | 880 ua | AW | 85 / Qhov kub thiab txias | 16 | |||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 350 | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 hli | ||||||

| ELECTRICITY (Amp) | H/W | 80-110 : kuv | 100-130 Nws | 130-180 Nws | 180-230 : kuv | |||||

| O/W | 50-80 | 90-120 : kuv | 130-160 : kuv | - | ||||||

Stability ntawm arc

Yooj yim slagging

mus rau boost, ua tej yam khoom zoo nyob rau hauv txoj kab nrog kev ua lag luam thiab buyer standard xav tau. Peb lub tuam txhab muaj cov txheej txheem kev ruaj ntseg zoo heev tshwm sim los tsim kom tau Zoo Tshaj Plaws Kub Muag Alloy Steel Vuam Electrodes E12015-G, Tam sim no, peb xav ua ntej kom muaj kev koom tes loj dua nrog cov neeg siv khoom txawv teb chaws raws li kev sib nrig sib zoo. Nco ntsoov xav tiv tauj peb kom paub meej ntxiv.

Zoo tshaj-muagTuam Tshoj Vuam Electrode thiab E12015-G, Raws li lub hauv paus ntsiab lus ntawm kev ua lag luam yog "ua lag luam-taw qhia, kev ntseeg zoo raws li txoj cai, yeej-yeej raws li lub hom phiaj", tuav ntawm "tus neeg siv khoom ua ntej, kev lees paub zoo, kev pabcuam ua ntej" raws li peb lub hom phiaj, mob siab rau muab qhov zoo tshaj plaws, tsim kev pabcuam zoo, peb yeej qhov kev qhuas thiab kev ntseeg siab hauv kev lag luam ntawm qhov chaw pib. Nyob rau hauv lub neej yav tom ntej, Peb yuav muab cov khoom zoo thiab cov kev pab zoo heev rov qab los rau peb cov neeg muas zaub, zoo siab txais tos cov lus qhia thiab tawm tswv yim los ntawm thoob plaws lub ntiaj teb no.

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | V |

| GB/T RULES | - | ≥1.00 Nws | ≥0.80 | ≥0.30 Nws | ≥0.50 | ≥0.20 | - | - | - | ≥0.10 |

| AWS RULES | - | ≥1.00 Nws | ≥0.80 | ≥0.30 Nws | ≥0.50 | ≥0.20 | 0.030 Nws | 0.030 Nws | ≥0.20 | ≥0.10 |

| EXAMPLE VALUE | 0.072 ib | 2.20 | 0.14 ib | 0.54 ib | 0.015 ib | 0.86 ib | 0.012 ib | 0.006 ib | 0.012 ib | 0.002 ib |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||

| GB/T RULES | 740 ib | 8 30 | AW | - | 12 | |||||

| AWS RULES | 740 ib | 8 30 | AW | - | 14 | |||||

| EXAMPLE VALUE | 820 | 880 ua | AW | 85 / Qhov kub thiab txias | 16 | |||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 350 | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 hli | ||||||

| ELECTRICITY (Amp) | H/W | 80-110 : kuv | 100-130 Nws | 130-180 Nws | 180-230 : kuv | |||||

| O/W | 50-80 | 90-120 : kuv | 130-160 : kuv | - | ||||||