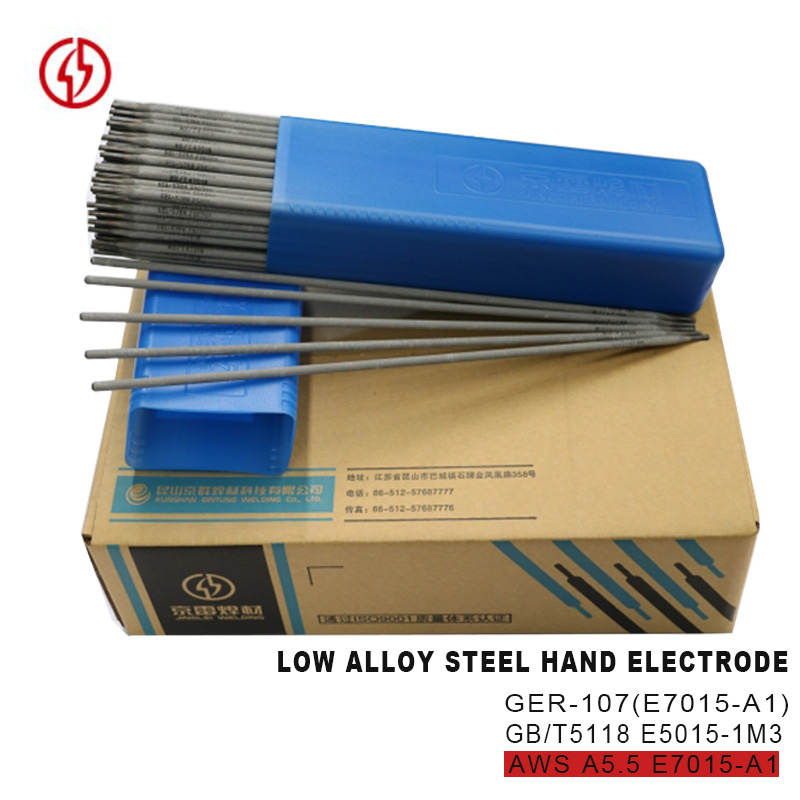

AWS E7015-A1 Low-alloy steels Manual electrode Welding accessories

Daim ntawv thov & Standard & Ceeb toom:

E7015 hom qis alloy steel tes electrode yog tsim rau vuam ua hauj lwm kub hauv qab 510 ℃ boiler yeeb nkab, tshav kub exchanger thiab lwm zaus, xws li ASTM A204 thiab A335-P1 yeeb nkab;

Cov electrode yuav tsum tau qhuav ua ntej siv, khaws lub arc luv luv, kev siv rov qab rau pem hauv ntej vuam txoj kev, zam qhov tshwm sim ntawm porosity ntawm lub arc; Tsawg hydrogen yuav tsum tau khaws cia thoob plaws hauv cov txheej txheem vuam. Tsawg alloy steel electrode xaiv, feem ntau yog raws li cov tshuaj muaj pes tsawg leeg ntawm cov hlau, cov khoom siv kho tshuab, tawg tsis kam thiab lwm yam kev xav tau, tab sis kuj los ntawm cov qauv vuam zoo, kev ua haujlwm, kev ntxhov siab thiab vuam cov cuab yeej thiab lwm yam kev xav tau. Yog tias tsim nyog, kev ntsuas kev ua haujlwm vuam yuav tsum tau ua los txiav txim siab cov electrode thiab cov txheej txheem tsim nyog yuav tsum tau ua.

Nta

1. Tsawg sodium hydrogen electrode, ntxiv 0.5% Mo los txhim kho vuam lub zog thiab corrosion kuj;

2. ruaj khov arc, tsis tshua muaj txaws, zoo tsim, yooj yim rau desagger, X-Ray kev ua tau zoo heev.

Feem ntau xaiv cov khoom siv electrode raws li lub zog ntawm qib steel, tib lub sijhawm kuj xav tau steel weldability, kev hloov pauv ntawm niam txiv cov khoom siv hlau, twv kom teb cov qauv loj, cov duab, zawj thiab cov ntsiab lus ntawm kev ntxhov siab, xws li kev nthuav dav. kev txiav txim siab, qhov txias ceev ntawm vuam yog loj dhau, yog lub zog siab dua, cov khoom siv vuam txoj kev yooj yim tawg cov xwm txheej tsis zoo, feem ntau tuaj yeem xaiv qee qhov tsawg dua lub zog ntawm niam txiv hlau electrode.

Tuam txhab & Hoobkas

Cov khoom muaj pes tsawg leeg thiab cov khoom siv kho tshuab kev taw qhia

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Mo | P | S |

| GB/T RULES | 0.12 | 1.00 Nws | 0.80 ib | - | 0.40-0.65 Nws | 0.03 ib | 0.030 Nws |

| AWS RULES | 0.12 | 0.90 ib | 0.60 ib | - | 0.40-0.65 Nws | 0.03 ib | 0.030 Nws |

| EXAMPLE VALUE | 0.07 ib | 0.75 ib | 0.35 Nws | 0.035 ib | 0.55 ib | 0.014 ib | 0.012 ib |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||||||

| GB/T RULES | 390 | 490 ib | 620 * 1 | - | 22 | |||||||||

| AWS RULES | 390 | 490 ib | 620 * 1 | - | 22 | |||||||||

| EXAMPLE VALUE | 477 ib | 570 ib | 620 * 1 | 150 / Qhov kub thiab txias | 28 | |||||||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 350 | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 hli | ||||||

| ELECTRICITY (Amp) | H/W | 80-110 : kuv | 100-130 Nws | 130-180 Nws | 170-210 : kuv | |||||

| O/W | 60-100 | 80-120 : kuv | 120-160 : kuv | - | ||||||

PACKING COV NTAUB NTAWV:

| 2.6mm ib | 300 hli | 48 Pcs | 2 KG | |||

| 3.2mm ib | 350 hli | 27 Pcs | 5 KG | |||

| 4.0mm ib | 350 hli | 16 Pcs | 5 KG | |||

| 5.0mm ib | 350 hli | 12 Pcs | 5 KG | |||

Cov xwm txheej

Daim ntawv pov thawj

Cov khoom muaj pes tsawg leeg thiab cov khoom siv kho tshuab kev taw qhia

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Mo | P | S |

| GB/T RULES | 0.12 | 1.00 Nws | 0.80 ib | - | 0.40-0.65 Nws | 0.03 ib | 0.030 Nws |

| AWS RULES | 0.12 | 0.90 ib | 0.60 ib | - | 0.40-0.65 Nws | 0.03 ib | 0.030 Nws |

| EXAMPLE VALUE | 0.07 ib | 0.75 ib | 0.35 Nws | 0.035 ib | 0.55 ib | 0.014 ib | 0.012 ib |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||||||

| GB/T RULES | 390 | 490 ib | 620 * 1 | - | 22 | |||||||||

| AWS RULES | 390 | 490 ib | 620 * 1 | - | 22 | |||||||||

| EXAMPLE VALUE | 477 ib | 570 ib | 620 * 1 | 150 / Qhov kub thiab txias | 28 | |||||||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 350 | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 hli | ||||||

| ELECTRICITY (Amp) | H/W | 80-110 : kuv | 100-130 Nws | 130-180 Nws | 170-210 : kuv | |||||

| O/W | 60-100 | 80-120 : kuv | 120-160 : kuv | - | ||||||

PACKING COV NTAUB NTAWV:

| 2.6mm ib | 300 hli | 48 Pcs | 2 KG | |||

| 3.2mm ib | 350 hli | 27 Pcs | 5 KG | |||

| 4.0mm ib | 350 hli | 16 Pcs | 5 KG | |||

| 5.0mm ib | 350 hli | 12 Pcs | 5 KG | |||