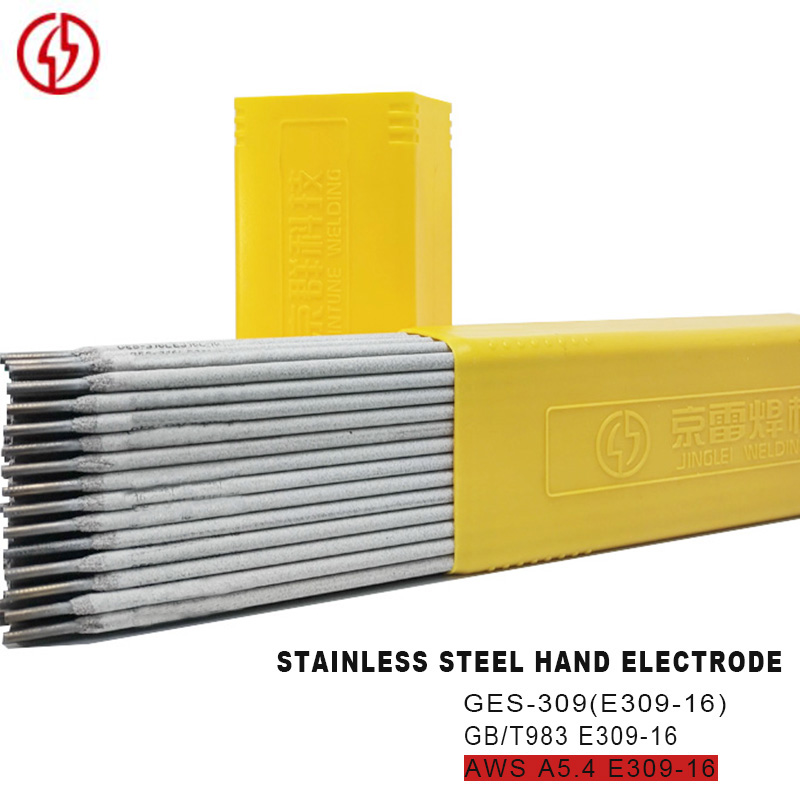

AWS E309-16 Stainless Steels Solid wire Vuam cov ntaub ntawv

Daim ntawv thov & Standard & Ceeb toom:

1. Haum rau STAINLESS STEEL THIAB CARBON STEEL LOS SIS LOW ALLOY steel DISsimilar STEEL welding, STAINLESS steel composite phaj cladding WELDING, 308 SERIES STAINLESS STEEL SURFACING Vuam ntawm carbon steel los yog tsawg alloy STEEL.

2. Tus qauv peb ntsib: GB/T983 E309-16, AWS A5.4 E309-16 & A5.4M E309-16, ISO3581-A:E(22 12) R 1 2, ISO3581-B:ES309-16

CHARACTERISTIS:

E309L-16 yog ib qho ultra-low carbon Cr23Ni13 stainless hlau electrode siv hauv rutile hom khoom siv siab. Hla - ncaj qha, tuaj yeem siv rau txhua txoj haujlwm vuam. Cov hlau tso tawm muaj cov pa roj carbon tsawg, yog li nws tuaj yeem tiv taus qhov sib txuam crystalline corrosion los ntawm carbide nag lossis daus thaum lub stabilizer xws li niobium thiab titanium tsis muaj.

Nta

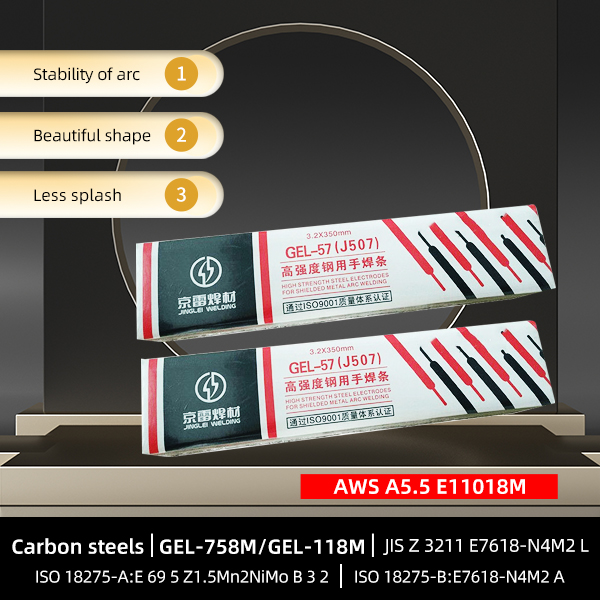

1. Titanium calcium stainless hlau electrode, lub ntsiab muaj pes tsawg leeg yog 22% CR-12% Ni;

2. ruaj khov arc, zoo nkauj sib sau, zoo ripples, ob peb splashes, yooj yim de-slagging, zoo hluav taws tsis kam ntawm cov tshuaj ntawm daim tawv nqaij, zoo stomatal kuj.

3. Cov hlau weld muaj ntau ferrite thiab muaj qhov tsis tshua muaj tawg.

A302 yog Cr23Ni13 stainless hlau electrode nrog titanium calcium txheej. Cov hlau molten muaj qhov zoo ntawm kev tawg thiab oxidation tsis kam. Ac-dc dual siv, cov txheej txheem kev ua haujlwm zoo. Txhawm rau txhim kho cov kab nrib pleb thiab corrosion tsis kam ntawm cov hlau molten, Mo cov ntsiab lus hauv 16 tau tsim nyog nce li ntawm 1%. Stainless hlau electrode feem ntau yog titanium calcium hom thiab tsawg hydrogen hom ob. Dc fais fab mov yog siv rau vuam tam sim no kom deb li deb tau los kov yeej redness thiab qhov tob ntawm vuam pas nrig. Titanium calcium txheej electrode tsis haum rau tag nrho txoj hauj lwm vuam, tsuas yog haum rau tiaj vuam thiab fillet vuam; Cov electrode uas tsis tshua muaj hydrogen txheej yuav siv tau rau tag nrho txoj hauj lwm vuam.

Tuam txhab & Hoobkas

Cov khoom muaj pes tsawg leeg thiab cov khoom siv kho tshuab kev taw qhia

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULES | 0.15 | 0.5-2.5 hli | 1.00 Nws | 22.0-25.0 Nws | 12.0-14.0 Nws | 0.75 ib | 0.040 ib | 0.03 ib | 0.75 ib |

| AWS RULES | 0.15 | 0.5-2.5 hli | 1.00 Nws | 22.0-25.0 Nws | 12.0-14.0 Nws | 0.75 ib | 0.040 ib | 0.03 ib | 0.75 ib |

| EXAMPLE VALUE | 0.046 ib | 1.35 Nws | 0.77 ib | 24.5 ib | 12.6 | 0.38 ib | 0.028 ib | 0.003 ib | 0.13 |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||||||

| GB/T RULES | - | 550 | - | - | 25 | |||||||||

| AWS RULES | - | 550 | - | - | 30 | |||||||||

| EXAMPLE VALUE | - | 617 ib | - | - | 38 | |||||||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.0 * 250 hli | 2.6 * 300 | 3.2 * 350 | 4.0 * 350 | 5.0 * 350 | |||||||

| ELECTRICITY (Amp) | H/W | 50-75 : kuv | 70-95 : kuv | 80-120 : kuv | 110-160 : kuv | 160-190 : kuv | ||||||

| O/W | 20-50 | 45-80 : kuv | 70-110 : kuv | 90-135 : kuv | - | |||||||

PACKING COV NTAUB NTAWV:

| SEPCIFICATION | LENGTH | PCS / 1 KG | NYIAJ / 1KG | |||

| 2.0 hli | 300 hli | 79pc ua | 2 KG | |||

| 2.6mm ib | 300 hli | 48 Pcs | 2 KG | |||

| 3.2mm ib | 350 hli | 27 Pcs | 5 KG | |||

| 4.0mm ib | 350 hli | 16 Pcs | 5 KG | |||

| 5.0mm ib | 350 hli | 12 Pcs | 5 KG | |||

CEEB TOOM:

H / W: kab rov tav txoj hauj lwm vuam

O / W: hla lub taub hau txoj hauj lwm vuam

Cov xwm txheej

Daim ntawv pov thawj

Cov khoom muaj pes tsawg leeg thiab cov khoom siv kho tshuab kev taw qhia

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULES | 0.15 | 0.5-2.5 hli | 1.00 Nws | 22.0-25.0 Nws | 12.0-14.0 Nws | 0.75 ib | 0.040 ib | 0.03 ib | 0.75 ib |

| AWS RULES | 0.15 | 0.5-2.5 hli | 1.00 Nws | 22.0-25.0 Nws | 12.0-14.0 Nws | 0.75 ib | 0.040 ib | 0.03 ib | 0.75 ib |

| EXAMPLE VALUE | 0.046 ib | 1.35 Nws | 0.77 ib | 24.5 ib | 12.6 | 0.38 ib | 0.028 ib | 0.003 ib | 0.13 |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||||||

| GB/T RULES | - | 550 | - | - | 25 | |||||||||

| AWS RULES | - | 550 | - | - | 30 | |||||||||

| EXAMPLE VALUE | - | 617 ib | - | - | 38 | |||||||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.0 * 250 hli | 2.6 * 300 | 3.2 * 350 | 4.0 * 350 | 5.0 * 350 | |||||||

| ELECTRICITY (Amp) | H/W | 50-75 : kuv | 70-95 : kuv | 80-120 : kuv | 110-160 : kuv | 160-190 : kuv | ||||||

| O/W | 20-50 | 45-80 : kuv | 70-110 : kuv | 90-135 : kuv | - | |||||||

PACKING COV NTAUB NTAWV:

| SEPCIFICATION | LENGTH | PCS / 1 KG | NYIAJ / 1KG | |||

| 2.0 hli | 300 hli | 79pc ua | 2 KG | |||

| 2.6mm ib | 300 hli | 48 Pcs | 2 KG | |||

| 3.2mm ib | 350 hli | 27 Pcs | 5 KG | |||

| 4.0mm ib | 350 hli | 16 Pcs | 5 KG | |||

| 5.0mm ib | 350 hli | 12 Pcs | 5 KG | |||

CEEB TOOM:

H / W: kab rov tav txoj hauj lwm vuam

O / W: hla lub taub hau txoj hauj lwm vuam