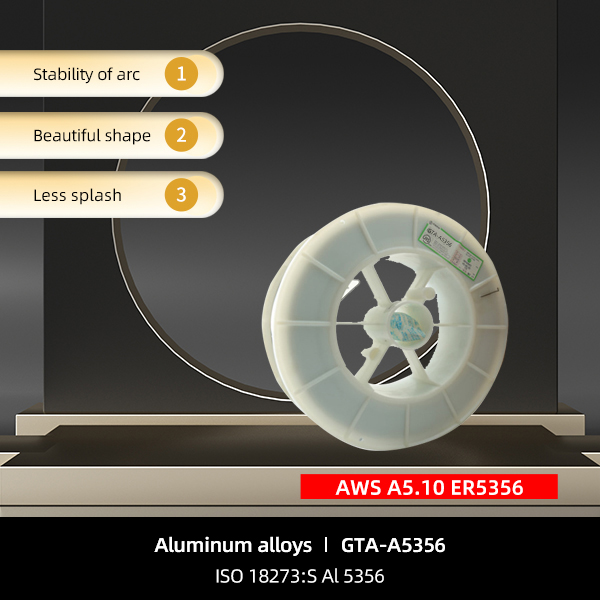

Aluminium alloys TIG ER5356 Vuam sib koom ua ke

CHEMICAL COMPNET:

| ALLOY (wt%) | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Be | S |

| GB/T RULES | 0.25 | 0.40 Nws | 0.10 | 0.05-0.2 hli | 4.5-5.5 | 0.05-0.2 hli | 0.10 | 0.06-0.2 hli | 0.0005 | Margin |

| AWS RULES | 0.25 | 0.40 Nws | 0.10 | 0.05-0.2 hli | 4.5-5.5 | 0.05-0.2 hli | 0.10 | 0.06-0.2 hli | 0.0008 | Margin |

| EXAMPLE VALUE | 0.15 | 0.10 | 0.03 ib | 0.15 | 5.2 | 0.1 | 0.05 Nws | 0.12 | 0.0003 | Margin |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | Niam txiv hlau | ELONGATION(%) | Kev kho cua sov | ||||||

| GB/T RULES | - | - | - | - | - | ||||||

| AWS RULES | - | - | - | - | - | ||||||

| EXAMPLE VALUE | 105 | 205 | Xyoo 2014-0 | 17 | AW | ||||||

Lub ntsiab tivthaiv yog ALMg5Cr.

k5% magnesium casting thiab forging aluminium alloy welding los yog nto nto, universal vuam khoom, siab zog, zoo malleability, zoo corrosion kuj.

Smooth hlau pub, ruaj khov arc combustion, txaws tsis tshua muaj kev zoo nkauj.

-

Vuam cov ntaub ntawv rau aluminium alloys

-

Polypropylene reactor

-

Gansu Lanke Petrochemical -50 ℃ propane kheej kheej tank project

CHEMICAL COMPNET:

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Be | S | |

| GB/T RULES | 0.25 | 0.40 Nws | 0.10 | 0.05-0.2 hli | 4.5-5.5 | 0.05-0.2 hli | 0.10 | 0.06-0.2 hli | 0.0005 | Margin |

| AWS RULES | 0.25 | 0.40 Nws | 0.10 | 0.05-0.2 hli | 4.5-5.5 | 0.05-0.2 hli | 0.10 | 0.06-0.2 hli | 0.0008 | Margin |

| EXAMPLE VALUE | 0.15 | 0.10 | 0.03 ib | 0.15 | 5.2 | 0.1 | 0.05 Nws | 0.12 | 0.0003 | Margin |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | Niam txiv hlau | ELONGATION(%) | Kev kho cua sov | ||||||

| GB/T RULES | - | - | - | - | - | ||||||

| AWS RULES | - | - | - | - | - | ||||||

| EXAMPLE VALUE | 105 | 205 | Xyoo 2014-0 | 17 | AW | ||||||

Sau koj cov lus ntawm no thiab xa tuaj rau peb