490Mpa Tes Electrode Rau Cov Hlau Hlau

Daim ntawv thov & Standard & Note

1. Haum rau welding ntawm CARBON STEEL thiab qis ALLOY STEEL, zoo li lub zog sib xws ntawm BOILER, pipeline, tsheb, Lub tsev, BRIDGE thiab lwm yam qauv, xws li Q345.

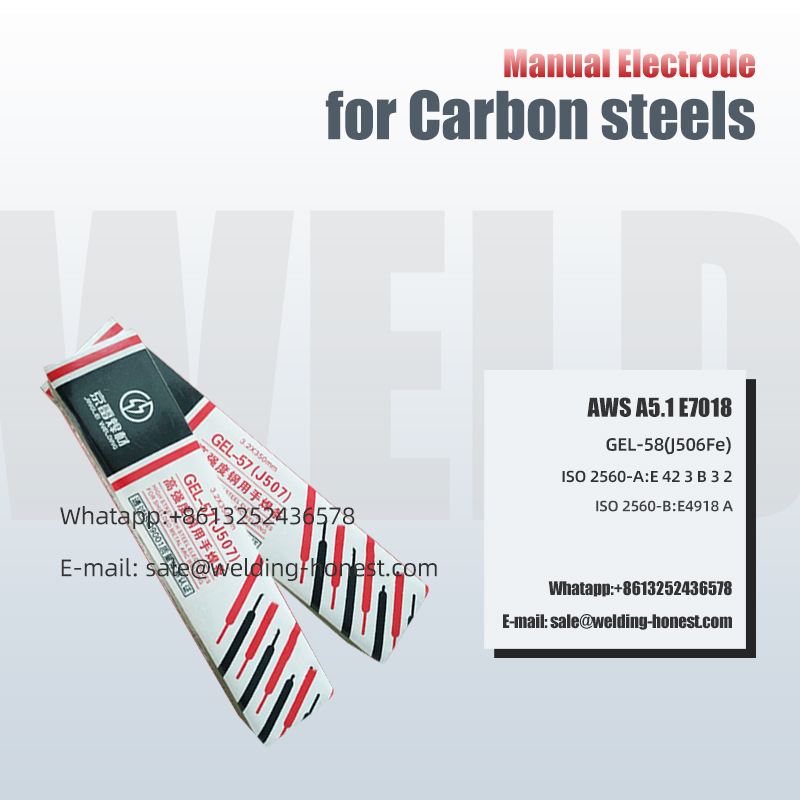

2. Tus qauv peb ntsib: GB/T5117 E5018, AWS A5.1 E7018 & A5.1M E4918, ISO2560-A:E 42 3 B 3 2, ISO 2560-B: E4918 A

Txij li thaum E7018 electrode tau yooj yim absorbs noo noo, nws yog khaws cia rau hauv qhov cub kom qhuav electrode. Cov electrode khaws cia hauv huab cua tuaj yeem rov ua dua ntawm 350 ~ 400 ℃ rau 1h ~ 2h. Nyob rau hauv thiaj li yuav restore lub zog ntawm daim tawv nqaij. Cov hlau me me tuaj yeem welded nrog unbaked E7018 electrodes, tab sis qhov kawg weld zog yuav tsis siab txaus.

Nta

Hlau hmoov tsis tshua muaj hydrogen hom tes electrode, siab vuam efficiency, ruaj khov arc, zoo nkauj sib sau, corrugations, me ntsis txaws, yooj yim de-slagging, tshuaj zoo tawv nqaij tiv taus, zoo stomatal kuj. Cov khoom siv ruaj khov, zoo plasticity thiab tsis tshua muaj kub cuam tshuam tenacity.

E7018 yog ib qho zoo carbon steel electrode nrog hlau hmoov uas tsis muaj hydrogen potassium txheej. Cov electrode muaj cov txheej txheem vuam zoo heev, arc rigidity yog qhov zoo, tsis yooj yim los tsim magnetic bias tshuab, vuam seam tsim zoo huv si thiab zoo nkauj, tsis tshua muaj txaws, slag yog ib qho yooj yim; Weld hlau muaj zoo heev thiab ruaj khov uas tsis muaj kub toughness thiab tawg kuj. Ac thiab DC dual siv, tuaj yeem nqa tag nrho txoj haujlwm vuam. Nws cov yam ntxwv yog tias cov tawv nqaij ntawm cov tshuaj muaj cov hmoov hlau, uas tuaj yeem txo cov welding txheej. Ci lub electrode ntawm 350 ~ 400 degrees Celsius rau 1 ~ 2 teev, thiab siv nrog ci. Feem ntau cov khoom siv hluav taws xob zoo no yog siv rau vuam nkoj hlau (A, B, D lossis E, A36, E36) thiab cov qauv tseem ceeb ntawm cov hlau tsis tshua muaj hlau ntawm tib qib ntawm lub zog, xws li boilers, siab hlab ntsha thiab offshore drilling platforms, lwm.

Tuam txhab & Hoobkas

Cov khoom muaj pes tsawg leeg thiab cov khoom siv kho tshuab kev taw qhia

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | 0.15 | 1.6 | 0.9 | 0.2 | 0.3 | 0.3 | 0.035 ib | 0.035 ib | 0.08 ib |

| AWS RULES | 0.15 | 1.25 | 0.9 | 0.2 | 0.3 | 0.3 | 0.035 ib | 0.035 ib | 0.08 ib |

| EXAMPLE VALUE | 0.075 ib | 1.17 | 0.5 | 0.04 ib | 0.02 ib | 0.007 ib | 0.017 ib | 0.009 ib | 0.01 ib |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | ELONGATION(%) | ||||||

| GB/T RULES | 400 | 490 ib | AW | 20 | ||||||

| AWS RULES | 400 | 490 ib | AW | 22 | ||||||

| EXAMPLE VALUE | 460 | 555 | AW | 30 | ||||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 350 | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 hli | |||||

| ELECTRICITY | H/W | 80-110 : kuv | 100-130 Nws | 130-180 Nws | 180-230 : kuv | ||||

| (Amp) | O/W | 50-80 | 90-120 : kuv | 130-160 : kuv | - | ||||

CEEB TOOM:

H / W: kab rov tav txoj hauj lwm vuam

O / W: hla lub taub hau txoj hauj lwm vuam

Cov xwm txheej

Daim ntawv pov thawj

Cov khoom muaj pes tsawg leeg thiab cov khoom siv kho tshuab kev taw qhia

CHEMICAL COMPNET:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | 0.15 | 1.6 | 0.9 | 0.2 | 0.3 | 0.3 | 0.035 ib | 0.035 ib | 0.08 ib |

| AWS RULES | 0.15 | 1.25 | 0.9 | 0.2 | 0.3 | 0.3 | 0.035 ib | 0.035 ib | 0.08 ib |

| EXAMPLE VALUE | 0.075 ib | 1.17 | 0.5 | 0.04 ib | 0.02 ib | 0.007 ib | 0.017 ib | 0.009 ib | 0.01 ib |

MECHANICAL PROPERTY:

| QHOV TSEEB | YIELD zog (MPa) | EXTENSION zog (MPa) | TUB ROG ℃ xh | ELONGATION(%) | ||||||

| GB/T RULES | 400 | 490 ib | AW | 20 | ||||||

| AWS RULES | 400 | 490 ib | AW | 22 | ||||||

| EXAMPLE VALUE | 460 | 555 | AW | 30 | ||||||

WELDING PARAMETERS pom zoo:

| DIAMETERS SPECIFICATIONS (mm) | 2.6 * 350 | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 hli | |||||

| ELECTRICITY | H/W | 80-110 : kuv | 100-130 Nws | 130-180 Nws | 180-230 : kuv | ||||

| (Amp) | O/W | 50-80 | 90-120 : kuv | 130-160 : kuv | - | ||||

CEEB TOOM:

H / W: kab rov tav txoj hauj lwm vuam

O / W: hla lub taub hau txoj hauj lwm vuam